Starch-based biodegradable plastic and preparation method thereof

A technology for degrading plastics and starch bases, applied in the field of degradable plastics, can solve the problems of limited improvement in mechanical properties, heat resistance and water resistance, lack of strong interaction, poor interface compatibility, etc., to achieve process and environment-friendly, Low cost and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

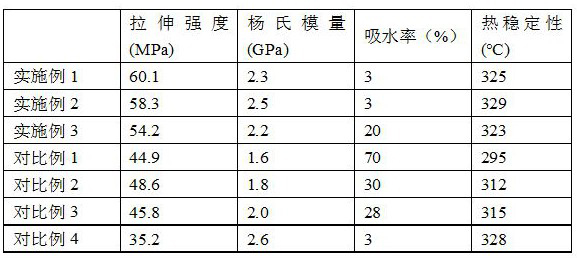

Examples

preparation example 1

[0039] A demethylated sulfonated lignin, the preparation method of which comprises: 100 mL of sodium lignosulfonate (Yates, SON-002) with a concentration of 0.1 g / mL and 20 mL of sodium lignosulfonate with a concentration of 0.7 g / mL Hydrobromic acid was added into a three-necked flask equipped with a stirring and reflux condensing device, and stirred and reacted at 100° C. for 6 h to obtain the demethylated sulfonated lignin.

[0040] The content of phenolic hydroxyl groups in the demethylated sulfonated lignin prepared in this preparation example is 6 mmol / g, and the content of sulfonic acid groups is 3 mmol / g.

preparation example 2

[0042] A kind of lignin modified nano mica, its preparation method comprises the steps:

[0043] (1) Put 100 g of muscovite (325 mesh) in a tube furnace and roast at 800 °C for 1 h to obtain roasted mica;

[0044] (2) Put 30 g of the roasted mica obtained in step (1) in 1 L of nitric acid with a concentration of 5 mol / L, and stir at 95°C for 5 h. After the reaction, cool to room temperature, filter, and deionize Washing with water several times until the filtrate is neutral to obtain mica treated with nitric acid;

[0045] (3) Add 10 g of mica obtained in step (2) into 0.1 g / mL demethylated sulfonated lignin solution (Preparation Example 1), and place it in a 325 W ultrasonic cleaner for 5 h After the treatment, centrifuge at 500 rpm to remove unstripped or larger-sized mica, and centrifuge the supernatant at 8000 rpm to obtain the lignin-modified nano-mica.

preparation example 3

[0047] A lignin-modified nano-mica, which differs from Preparation Example 2 only in that the demethylated lignin in step (3) is replaced with undemethylated sulfonated lignin (Yates, SON-002). Sulfonated lignin, other conditions and steps are the same as in Preparation Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com