Thermochromic adhesive tape and preparation method thereof

A thermochromic and tape technology, applied in the direction of adhesives, other rubber adhesives, film/sheet adhesives, etc., can solve the problem of untimely temperature monitoring of thermochromic tapes, and achieve stable viscosity and temperature Perceived Precise, Easily Monitored Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

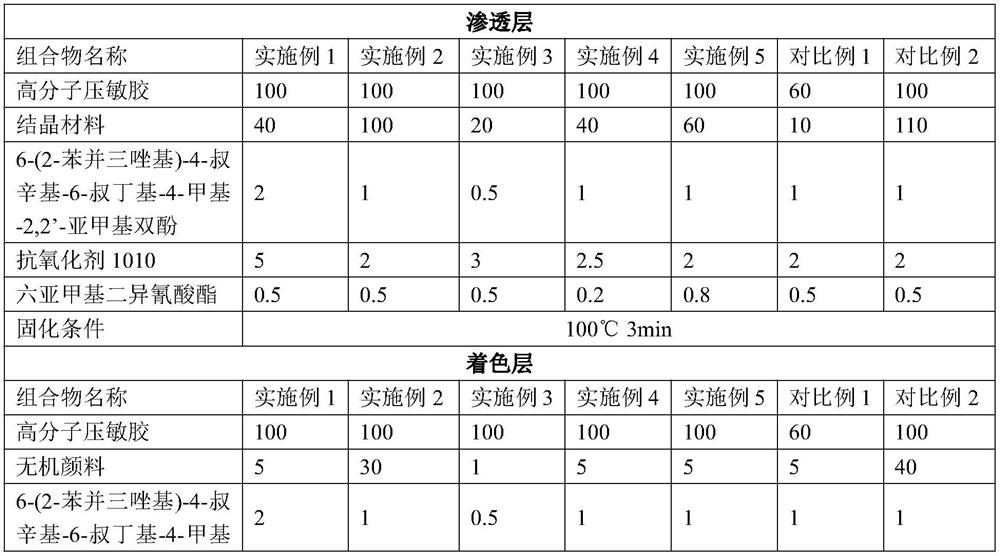

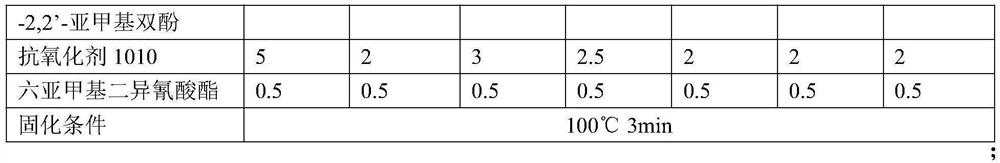

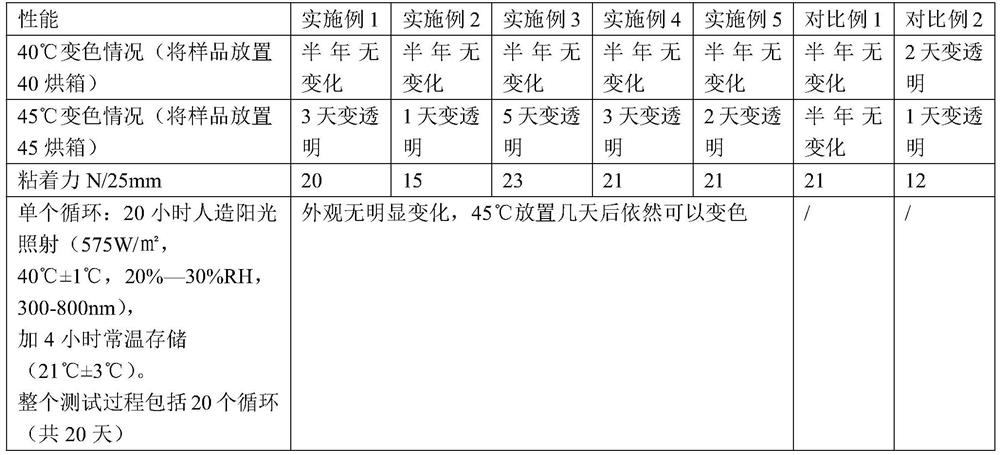

Embodiment 1

[0033] The polymer pressure-sensitive adhesive of the permeable layer in embodiment 1 is selected from rubber, and the crystallization material is selected from paraffin; the polymer pressure-sensitive adhesive of the colored layer is selected from acrylic resin; the thickness of the permeable layer is 5 μm, and the porous film is opaque PP porous The thickness of the film is 5 μm, and the thickness of the colored layer is 20 μm.

Embodiment 2

[0034] Example 2 The polymer pressure-sensitive adhesive of the permeable layer is selected from acrylic resin, and the crystal material is selected from palmitic acid; the polymer pressure-sensitive adhesive of the colored layer is selected from acrylic resin; the thickness of the permeable layer is 10 μm, and the porous membrane is white The PP porous membrane has a thickness of 25 μm, and the thickness of the colored layer is 100 μm.

Embodiment 3

[0035] Polyurethane is selected as the polymeric pressure-sensitive adhesive of the permeable layer in Example 3, and dicyclohexyl phthalate is selected as the crystalline material; polyurethane is selected as the polymeric pressure-sensitive adhesive of the colored layer; the thickness of the permeable layer is 20 μm, and the porous membrane It is a white PP porous film with a thickness of 50 μm, and the thickness of the colored layer is 100 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com