Composite yeast agent for fermentation production of alcohol and application of composite yeast agent

A technology of compound yeast and beer yeast, applied in the field of microorganisms, can solve the problems of lager beer monotonous flavor, increase beer ester aroma content, limit practicality, etc., and achieve the effect of retaining nutrients, rich ester aroma and unique style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11 and comparative example 1-5

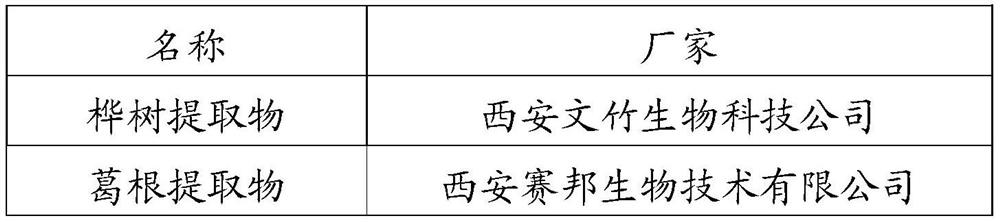

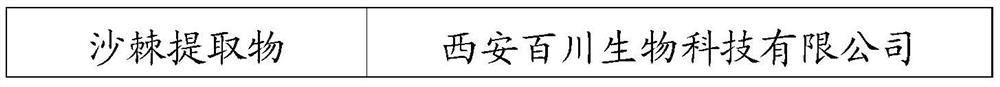

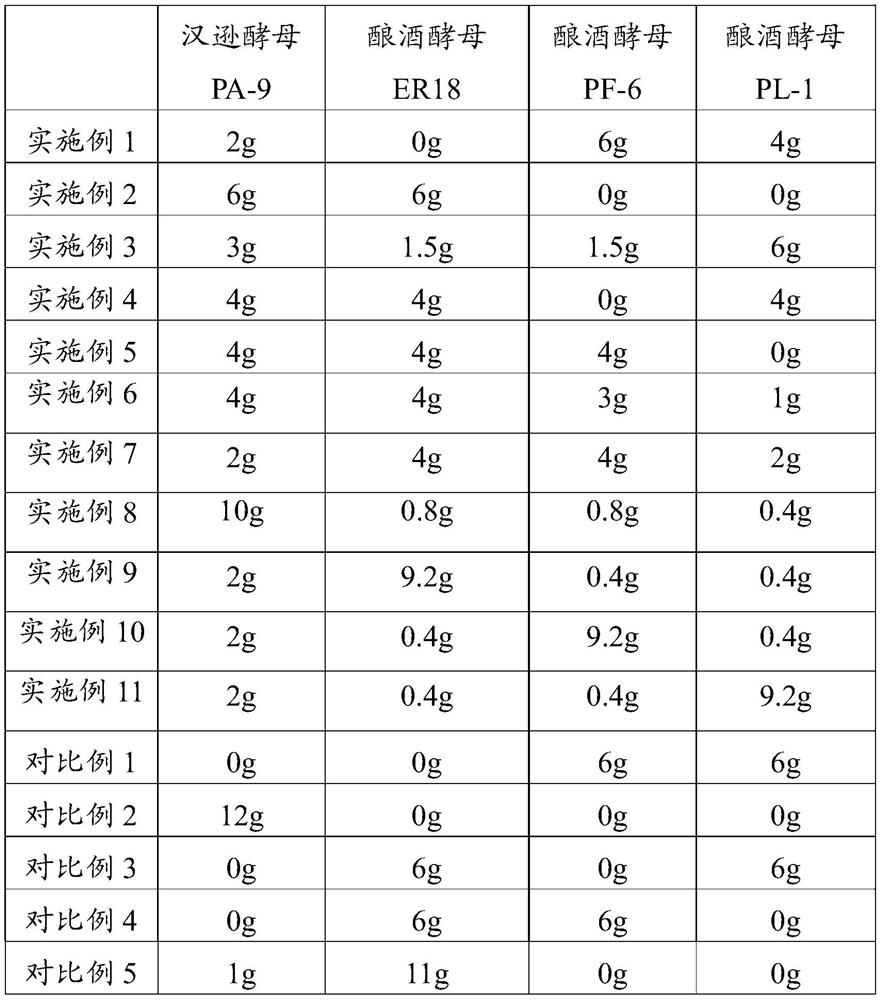

[0071] Weigh Hansenulae PA-9, Saccharomyces cerevisiae ER18, Saccharomyces cerevisiae PF-6 and Saccharomyces cerevisiae PL-1 as shown in Table 2, and mix well to obtain the composite bacteria of Examples 1-11 and Comparative Examples 1-5 agent.

[0072] Table 2

[0073]

Embodiment 12

[0074] Example 12 Composite yeast agent fermented birch juice wine

[0075] (1) Yeast activation: before fermentation, Hansenula PA-9, Saccharomyces ER18, Saccharomyces PF-6 and Saccharomyces PL-1 were mixed according to Example 1-11 groups and Comparative Example 1-5 groups, and the mixed Sprinkle the dry yeast in 120g of sterile saline at 28°C, let it stand for 10 minutes, and stir gently for 5-10 minutes until it is completely dissolved.

[0076] (2) Fermentation medium adjustment: 18 L of birch sap concentrate. Add 22% sucrose and 2% yeast extract powder to the concentrated juice, and adjust the pH value of the medium to 3.50 with citric acid.

[0077] (3) Fermentation: Put the activated mixed yeast liquid into the treated birch sap, and control the main fermentation temperature at 25°C. When the residual sugar in the fermentation liquid reaches below 4g / L, seal the tank and post-ferment for 30 days , into the aging tank, aging for 3 months.

[0078] The alcohol content...

Embodiment 13

[0081] Example 13 Composite yeast agent fermented low-alcohol kudzu root drink

[0082] (1) Yeast activation: before fermentation, Hansenula PA-9, Saccharomyces ER18, Saccharomyces PF-6 and Saccharomyces PL-1 were mixed according to Example 1-11 groups and Comparative Example 1-5 groups, and the mixed Sprinkle the dry yeast in 120g of sterile saline at 28°C, let it stand for 10 minutes, and stir gently for 5-10 minutes until it is completely dissolved.

[0083] (2) Adjustment of fermentation medium: dilute the extracted and concentrated Pueraria root liquid to 10 times, add 3% sucrose and 0.5% yeast extract powder to the Pueraria root extract, and adjust the pH of the medium to 5.20 with citric acid.

[0084] (3) Fermentation: The activated mixed yeast liquid reaches the treated plant extract, the main fermentation temperature is controlled at 20°C for 2 days, the tank is sealed and the pressure is increased, and the pressure is kept at 0.11MPa, and post-fermentation is carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com