Thaflavin composition, preparation method and application

A theaflavin and composition technology, applied in the field of theaflavin composition and preparation, can solve the problems of oral flora imbalance, obvious side effects, excessive intake of fluorine, etc., achieve antibacterial taste, improve extraction effect, increase yield rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

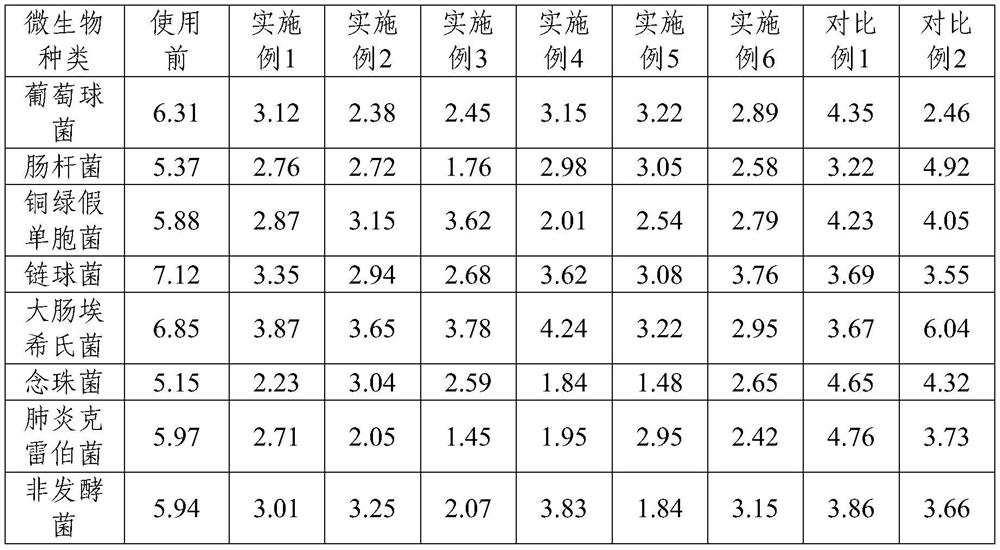

Examples

Embodiment 1

[0027]The theaflavin composition comprises the following components: 5 parts of theaflavins, 80 parts of black plum extract, 60 parts of honeysuckle extract, 90 parts of cassia seed extract and 4 parts of licorice extract. The preparation method of the ebony extract includes the steps of extraction, filtration, re-extraction, re-filtration, concentration, and drying; the extraction step is as follows: remove the core and pulverize the ebony, dry it at 15°C for 1 hour to constant weight, and add water It is 8 times of the dry weight of black plum, and boiled for 25 minutes; the re-extraction step is: adding water to the filter cake obtained in the filtering step and boiling for 15 minutes, and the amount of water added is 5 times of the dry weight of black plum; the concentration step is: filtering and re-extracting The filtrates obtained in the filtration step were combined and concentrated, and the concentration was stopped when the solid content reached 92%, and the obtained ...

Embodiment 2

[0029] The theaflavin composition comprises the following components: 25 parts of theaflavins, 120 parts of black plum extract, 80 parts of honeysuckle extract, 110 parts of cassia seed extract and 15 parts of licorice extract. The preparation method of the ebony extract includes the steps of extraction, filtration, re-extraction, re-filtration, concentration, and drying; the extraction step is as follows: the ebony is denuclearized and pulverized, dried at 25°C for 3 hours to constant weight, and the amount of water added It is 15 times of the dry weight of black plum, and boiled for 65 minutes; the re-extraction step is: adding water to the filter cake obtained in the filtering step and boiling for 60 minutes, and the amount of water added is 12 times of the dry weight of black plum; the concentration step is: filtering and re- The filtrates obtained in the filtration step were combined and concentrated, and when the solid content reached 98%, the concentration was stopped, a...

Embodiment 3

[0031] The theaflavin composition comprises the following components: 10 parts of theaflavins, 100 parts of black plum extract, 70 parts of honeysuckle extract, 100 parts of cassia seed extract and 10 parts of licorice extract. The preparation method of the ebony extract includes the steps of extraction, filtration, re-extraction, re-filtration, concentration, and drying; the operation of the extraction step is: remove the core and pulverize the ebony, dry it at 20°C for 2 hours to constant weight, and add water It is 10 times of the dry weight of black plum, and boiled for 30 minutes; the re-extraction step is: adding water to the filter cake obtained in the filtering step and boiling for 30 minutes, and the amount of water added is 10 times of the dry weight of black plum; the concentration step is: filtering and re- The filtrates obtained in the filtration step were combined and concentrated, and the concentration was stopped when the solid content was 95%, and the obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com