Microporous polyurethane elastomer sandwich structure and preparation method thereof

A technology of polyurethane elastomer and polyurethane elasticity, which is applied in the direction of polyurea/polyurethane adhesive, chemical instruments and methods, film/sheet without carrier, etc., can solve the problem of weak mechanical bearing capacity of unconstrained polyurethane elastomer and composite material damping Weak vibration damping performance and other issues, to reduce fatigue damage, increase interface strength, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

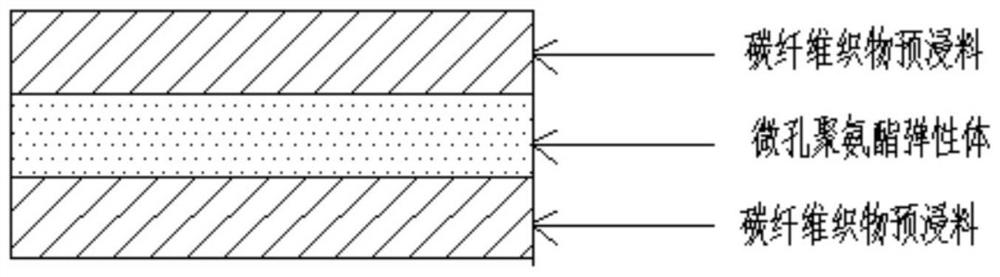

[0055] Such as figure 1 Shown, a kind of microporous polyurethane elastomer sandwich structure, this sandwich structure comprises two skins and a sandwich material, is a sandwich material between two skins;

[0056] The skin is carbon fiber prepreg, and the surface density of carbon fiber is 200g / m 2 , the fabric type is plain weave, and the matrix resin is epoxy resin;

[0057] The sandwich material is a microcellular polyurethane elastomer, and the density of the microcellular polyurethane elastomer is 350kg / cm 3 , dynamic and static stiffness ratio ≤ 1.35, static load limit ≥ 0.1N / mm 2 , the closed cell rate is ≥80%, and the thickness is 0.5mm; the two skins are the upper skin and the lower skin, the upper skin is 5 layers of carbon fiber prepreg, and the lower skin is 10 layers of carbon fiber prepreg;

[0058] The upper surface of the sandwich material is the upper skin, and the sandwich material and the upper skin are bonded with an epoxy resin film, the lower surface...

Embodiment 2

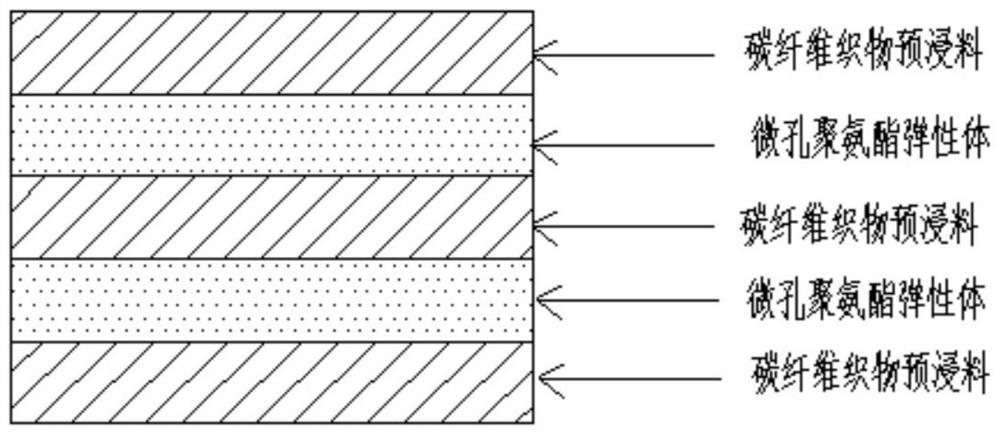

[0070] Such as figure 2 Shown, a kind of microporous polyurethane elastomer sandwich structure, this sandwich structure comprises three-layer skin and two-layer sandwich material; Between two skins is a sandwich material;

[0071] The skin is carbon fiber prepreg, and the surface density of carbon fiber is 200g / m 2 , the fabric type is plain weave, and the matrix resin is epoxy resin;

[0072] The sandwich material is a microcellular polyurethane elastomer, and the density of the microcellular polyurethane elastomer is 600kg / cm 3 , dynamic and static stiffness ratio ≤ 1.35, static load limit ≥ 0.1N / mm 2 , closed cell rate ≥ 80%, thickness 0.5mm;

[0073] The three-layer skin is the upper skin, the middle skin and the lower skin, the two-layer sandwich material is the upper sandwich material and the lower sandwich material respectively, and the upper sandwich material is between the upper skin and the middle skin. Between the middle skin and the lower skin is the lower san...

Embodiment 3

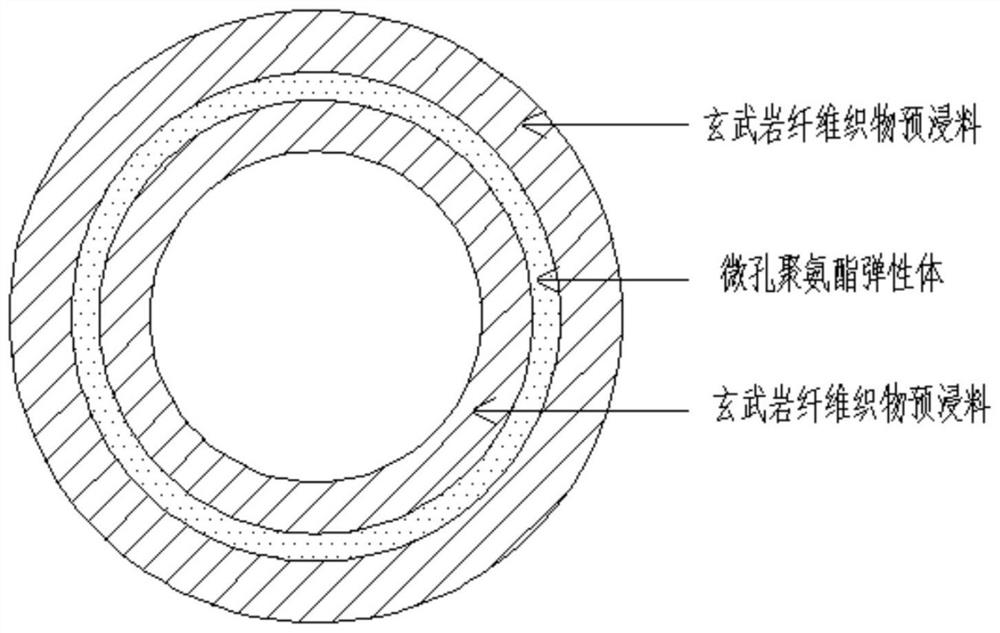

[0084] Such as image 3 As shown, a microporous polyurethane elastomer sandwich structure, the sandwich structure is a cylindrical structure, including two layers of skins and a layer of sandwich material; between the two skins is a sandwich material;

[0085] The skin is basalt fiber prepreg, and the surface density of basalt fiber is 200g / m 2 , the fabric type is plain weave, and the matrix resin is epoxy resin;

[0086] The sandwich material is a microcellular polyurethane elastomer, and the density of the microcellular polyurethane elastomer is 400kg / cm 3 , dynamic and static stiffness ratio ≤ 1.35, static load limit ≥ 0.1N / mm 2 , closed cell rate ≥ 80%, thickness 1mm;

[0087] The two skins are respectively an outer skin and an inner skin, and a sandwich material is between the outer skin and the inner skin;

[0088] The outer skin is used as the outer side of the tube wall of the cylindrical structure, and the outer side of the tube wall is 8 layers of basalt fiber p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com