Processing device for gel patch

A processing device and gel patch technology, which is applied in the direction of making medicines into special physical or taking forms, transportation and packaging, thin material processing, etc., can solve poor stability, increase the radial runout of pressure rollers, Problems such as large fluctuations in gram weight, to achieve the effect of reducing radial runout, reducing rotational vibration, and alleviating unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the present invention will be further described:

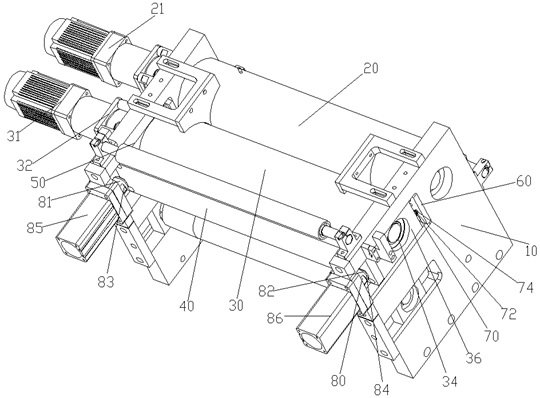

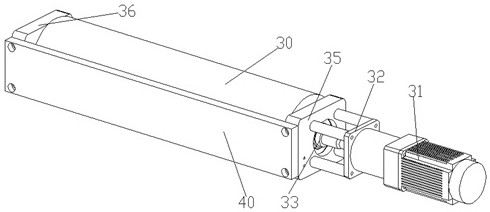

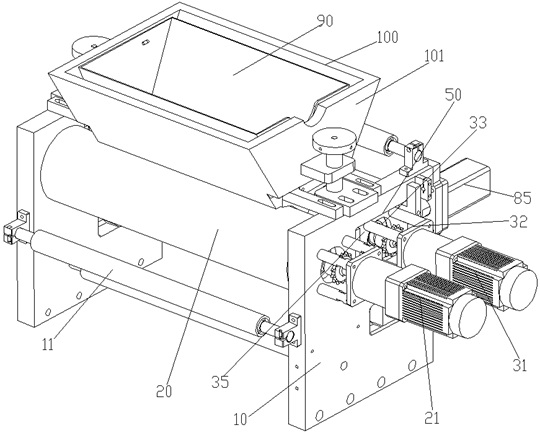

[0023] Such as Figure 1 to Figure 5Shown, the processing device of this gel patch comprises support 10, is provided with on support 10 and is used for storing and releasing the first unwinding roller 11 of base cloth, is used for storing and releasing the second unwinding of cover cloth. Roll (not shown in the drawings), the first squeeze roll 20 and the second squeeze roll 30 for extrusion molding, and the first unwind roll 11, the second unwind roll, the first squeeze roll 20 and The second squeeze roller 30 can be rotated, leaving a gap between the first squeeze roller 20 and the second squeeze roller 30, the base cloth released by the first unwinding roller 11, the cover released by the second unwinding roller The cloth and the gel paste between the first squeeze roller 20 and the second squeeze roller 30 are co-extruded by the first squeeze roller 20 and the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com