Method for adsorbing nitrosodiethylamine in water based on modified activated carbon

A nitrosodiethylamine, activated carbon adsorption technology, applied in adsorption water/sewage treatment, chemical instruments and methods, water pollutants and other directions, can solve problems such as low adsorption rate, achieve high adsorption efficiency, save follow-up work, Effects without toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

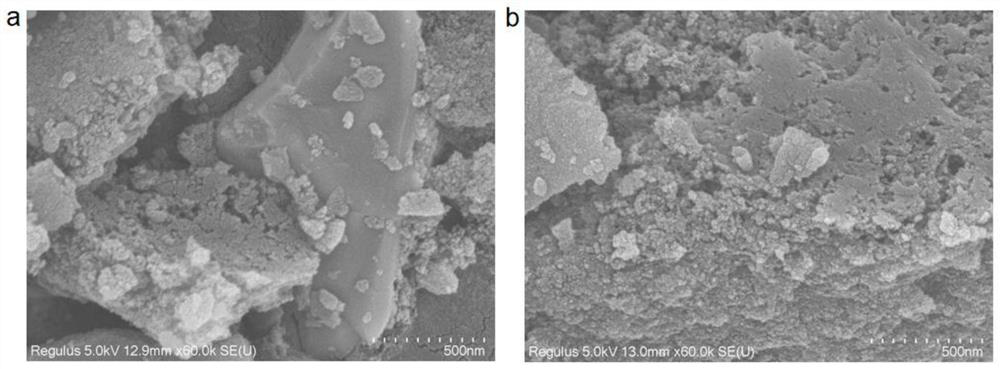

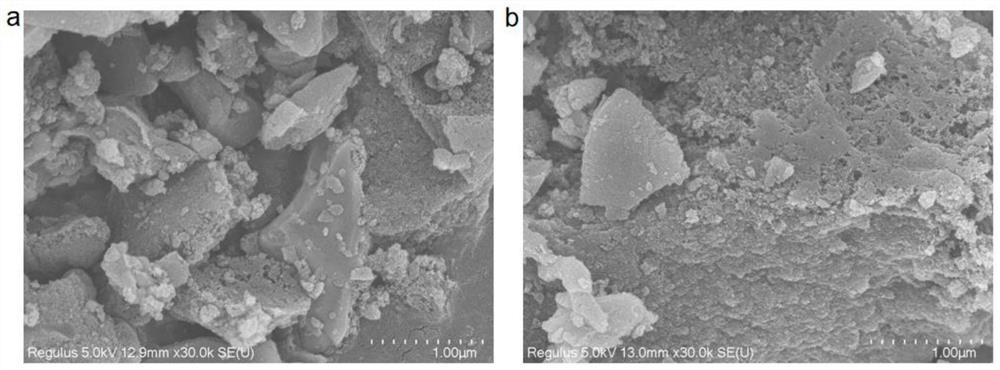

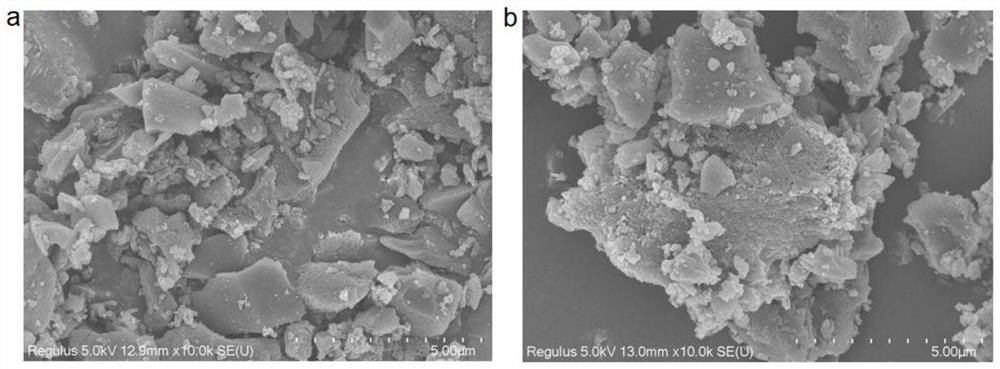

Image

Examples

Embodiment 1

[0035] Embodiment 1: Activated carbon modification condition screening

[0036] Weigh a certain amount of activated carbon washed with deionized water and dried, and mainly consider the influence of three factors including permanganate concentration, roasting temperature and roasting time on the adsorption performance. A total of 18 groups of screening tests for activated carbon modification conditions were carried out. At pH = 7, three groups of single-factor level tests were set up through the single-factor control method. Permanganate presoaking, in which the roasting temperature was set to 200°C, 300°C, 400°C, 500°C, 600°C, 800°C, a total of six sets of tests, and the roasting time was set to 1h, 2h, 3h, 4h, 5h, 7h A total of six groups of tests were carried out, and a total of 18 groups of modified activated carbons were prepared through the above steps.

[0037] Weigh 0.5g of the above-mentioned 18 kinds of modified activated carbon and original powdered activated carbo...

Embodiment 2

[0046] Embodiment 2: the screening of adsorption reaction condition

[0047] This embodiment mainly considers the influence of adsorption time, pH and dosage on the adsorption effect. Take different amounts of modified activated carbon and add them to pH 3, 4, 5 with the amount of 0.2g / L, 0.4g / L, 0.6g / L, 0.8g / L, 1g / L, 1.2g / L respectively. , 6, 7, 8, 9 in 500mL water containing nitrosodiethylamine at the same concentration (50mg / L), after reacting for 0.5h, 1h, 2h, 3h, 4h, 5h, 6h, calculate the NDEA Adsorption effect.

[0048] The results show that when the dosage of modified activated carbon is 0.6g / L, 0.8g / L, 1g / L, the reaction time is 2 h, 5h and 6h, and the pH of the solution is 6, 8, 9, the adsorption effect on NDEA is better it is good. Therefore, according to the above results, a three-factor three-level orthogonal test was carried out to screen the adsorption reaction conditions with the best adsorption effect on nitrosodiethylamine. Among them, the factors and leve...

Embodiment 3

[0057] A method for adsorbing nitrosodiethylamine in water based on modified activated carbon, comprising the following specific steps:

[0058] S1. Modification of activated carbon: Wash the original activated carbon with deionized water, filter, and then bake in an oven at 80°C for 8 hours. Take 100 g of the dried activated carbon and place it in 1 L of permanganate with a concentration of 0.8 mol / L. Pre-soak in salt solution for 24 hours, and then place the pre-soaked activated carbon in a muffle furnace with a temperature of 400 °C for 7 hours to obtain modified activated carbon;

[0059] S2. Adsorption of nitrosodiethylamine: Add the modified activated carbon obtained in S1 to the water body containing nitrosodiethylamine at a dosage of 0.8g / L, control the pH of the water body to 6, and measure the water body after 6 hours of reaction The content of nitrosodiethylamine in the medium was calculated to obtain the adsorption rate of modified activated carbon to nitrosodiethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com