Aluminosilicate glass, preparation method thereof and cover plate glass

A technology of silicate glass and alkali aluminum, which is applied in the field of aluminosilicate glass and its preparation method and cover glass, can solve the problems of material composition, strength performance, and difficulty in industrialization, and achieve crystallization that is not easy , the effect of excellent strength performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

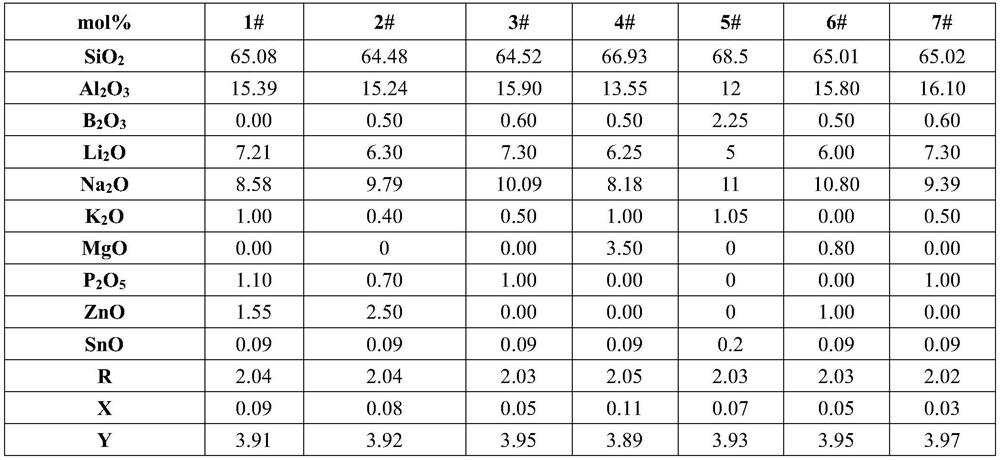

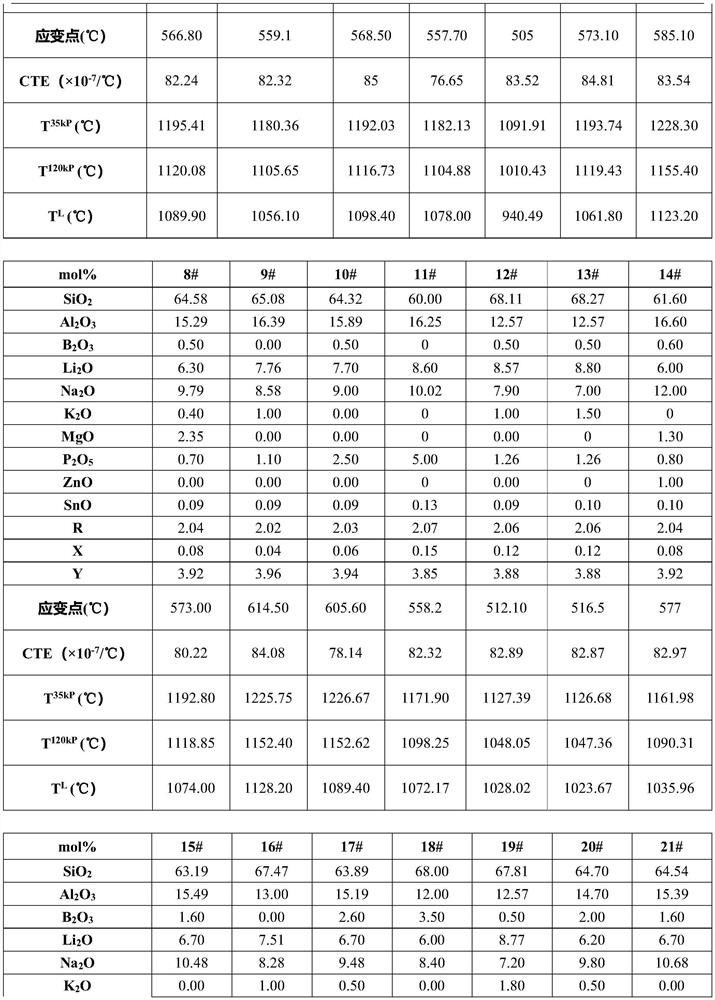

[0039] Unless otherwise stated, the coefficient of thermal expansion (CTE) in the present invention represents the measured value in the temperature range of about 25°C to 380°C, and its unit is (×10 -7 / °C).

[0040]All temperatures referred to in the present invention are expressed in degrees Celsius (° C.) unless otherwise indicated. The term "strain point" used in the present invention refers to a glass with a viscosity of about 10 13.6 Poise (P) when the temperature, the term "200P temperature (T 200P )" refers to the temperature at which the glass viscosity is 200 poise (P), and the term "35kP temperature (T 35kP )" refers to the temperature at which the glass viscosity is 35 kilopoises (kP), and the term "120kP temperature (T 120kP )" refers to the temperature at which the glass viscosity is 120 kilopoises (kP), and the term "crystallization upper limit temperature (T L )" means the temperature at which crystals first appear as the molten glass cools from the meltin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strain point | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com