Preparation method of high-heating electric shock curing concrete structure

A technology for concrete structure and heat generation, which is applied to clay preparation devices, chemical instruments and methods, and manufacturing tools, etc., can solve the problems of waste of electric power resources, less research on the electric and heat performance of concrete structures, and limitation of the effect of electric excitation maintenance, etc., so as to save energy. The effect of construction cost, high curing temperature and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention provides a kind of preparation method (abbreviation method) of high-heat electric excitation curing concrete structure, it is characterized in that, this method comprises the following steps:

[0026] Step 1, preparation of dry material:

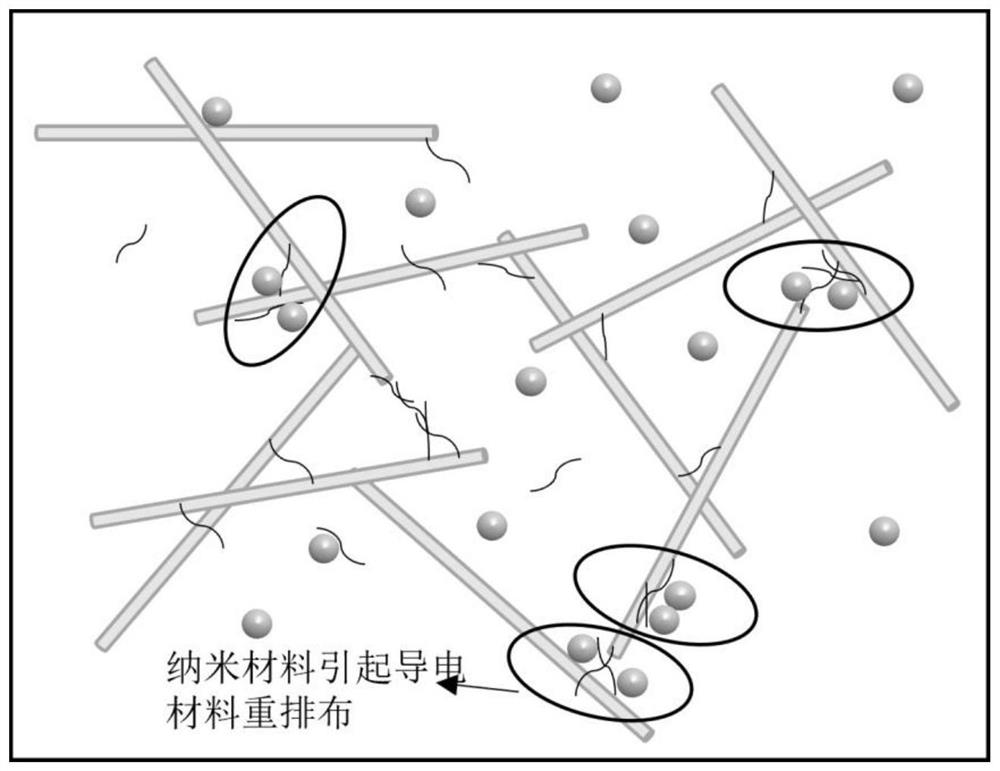

[0027] Mixing fine aggregate, non-conductive nanomaterials and conductive nanomaterials and fully stirring to obtain dry material A;

[0028] Mix the gelling material and the conductive filler and stir well to obtain the dry material B;

[0029] Preferably, in step 1, the fine aggregate includes at least one of standard sand, quartz sand, tailings sand or waste concrete aggregate, and the particle size of the fine aggregate is not greater than 2.5mm;

[0030] Preferably, in step 1, the non-conductive nanomaterial includes at least one of nano-silicon dioxide, nano-titanium dioxide, nano-calcium carbonate, nano-alumina or nano-aluminum nitride; more preferably, the non-conductive nano-material includes nano-scale...

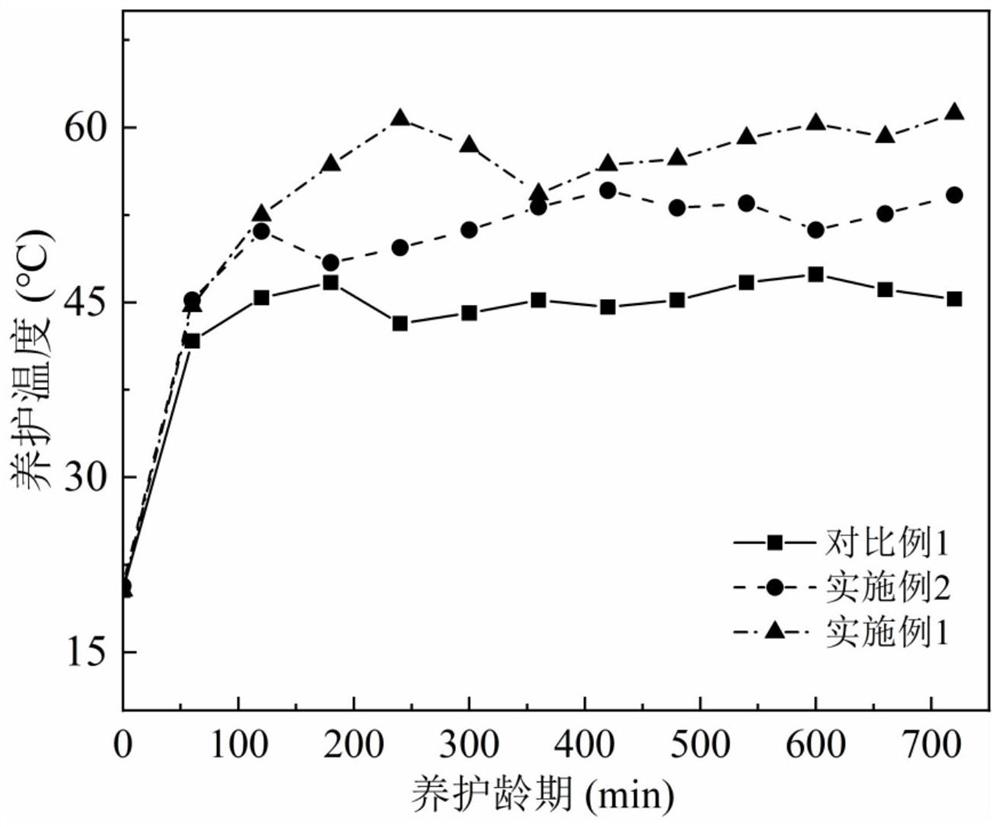

Embodiment 1

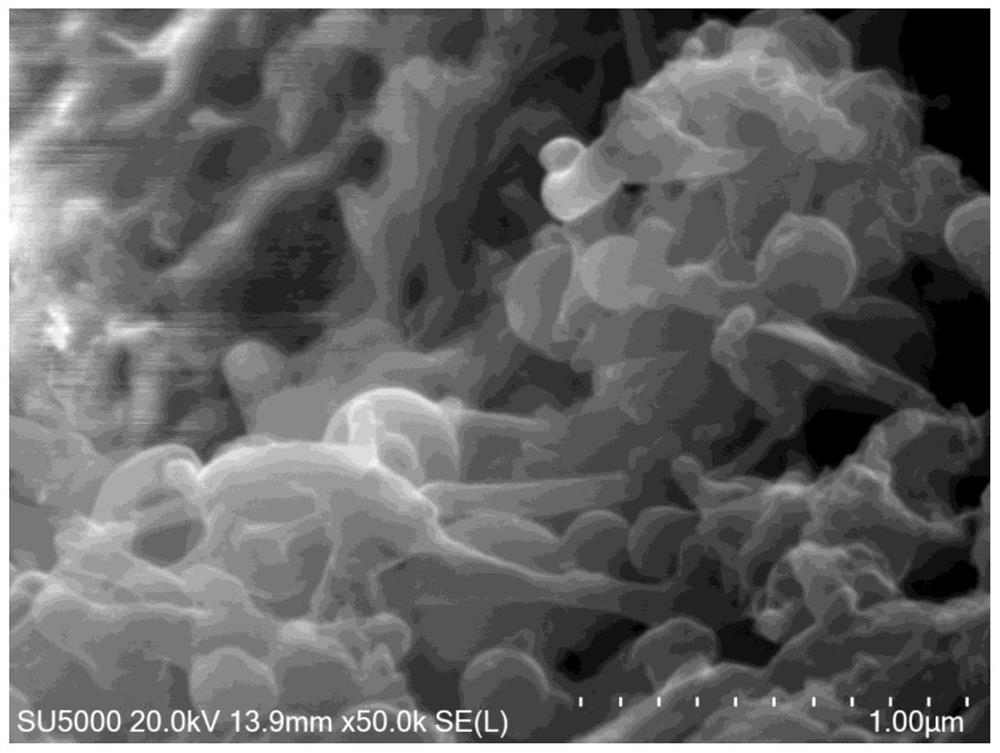

[0056] (1) Preparation of dry material: mix standard sand, nano-silica and nano-carbon fiber and stir for 15 minutes to obtain dry material A; mix cement and carbon fiber and stir for 4 minutes to obtain dry material B;

[0057] (2) Preparation of non-conductive nanomaterial-modified concrete material: Mix dry material A and dry material B, stir slowly for 3 minutes, then stir quickly for 5 minutes until uniform, then add water and water reducer and stir quickly for 8 minutes until uniform, and get Non-conductive nanomaterials modified concrete materials;

[0058] The mass ratio of cement to standard sand is 1:1, nano-silica accounts for 0.8wt% of the cement mass, nano-carbon fiber accounts for 0.2vol% of the volume of the non-conductive nanomaterial-modified concrete material, and carbon fiber accounts for 0.2vol% of the volume of the non-conductive nano-material-modified concrete The volume of the material is 0.75vol%, the water-binder ratio is 0.3, and the water reducing ag...

Embodiment 2

[0062] It is exactly the same as Example 1, the difference is that nano-silica accounts for 0.4wt% of the mass of the gelled material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com