Hydrodynamic force capturing, collecting and energy converting device

An energy conversion device and fluid power technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of high energy loss, no energy collection, long conversion process, etc., to improve efficiency, reduce resistance, reduce The effect of intermittent window periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

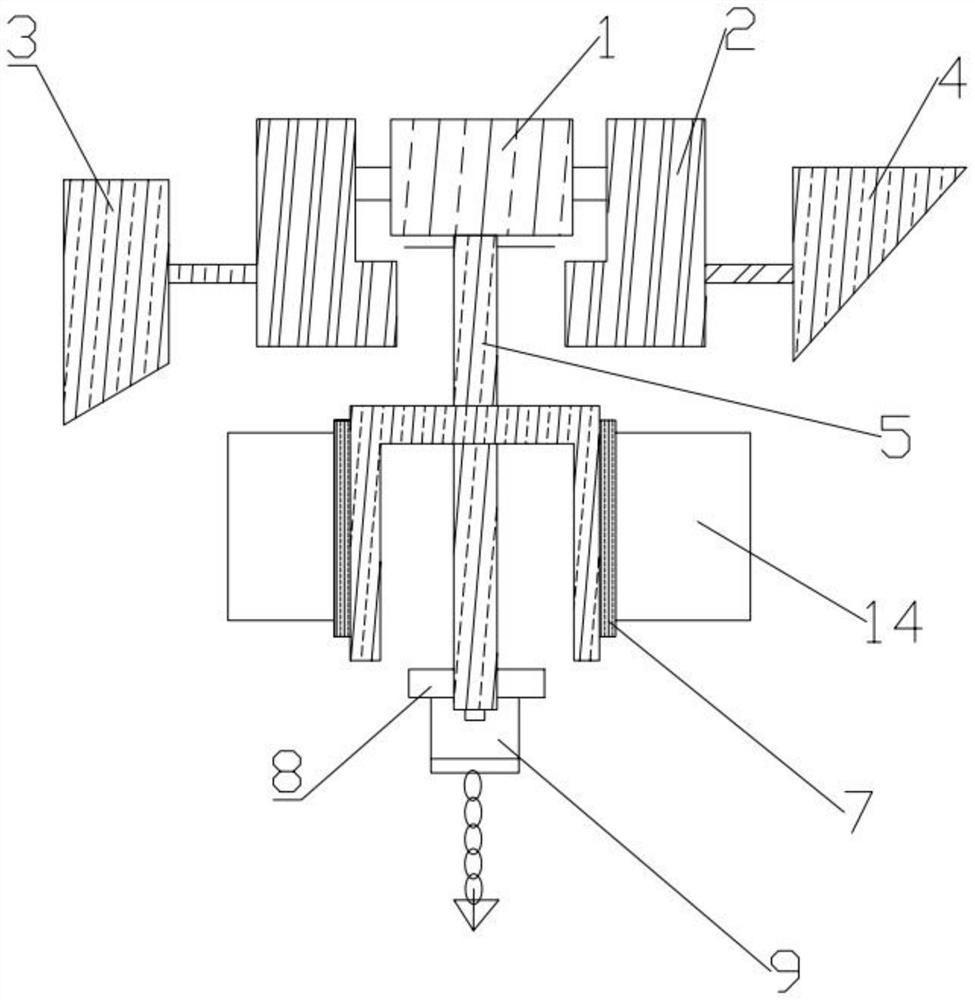

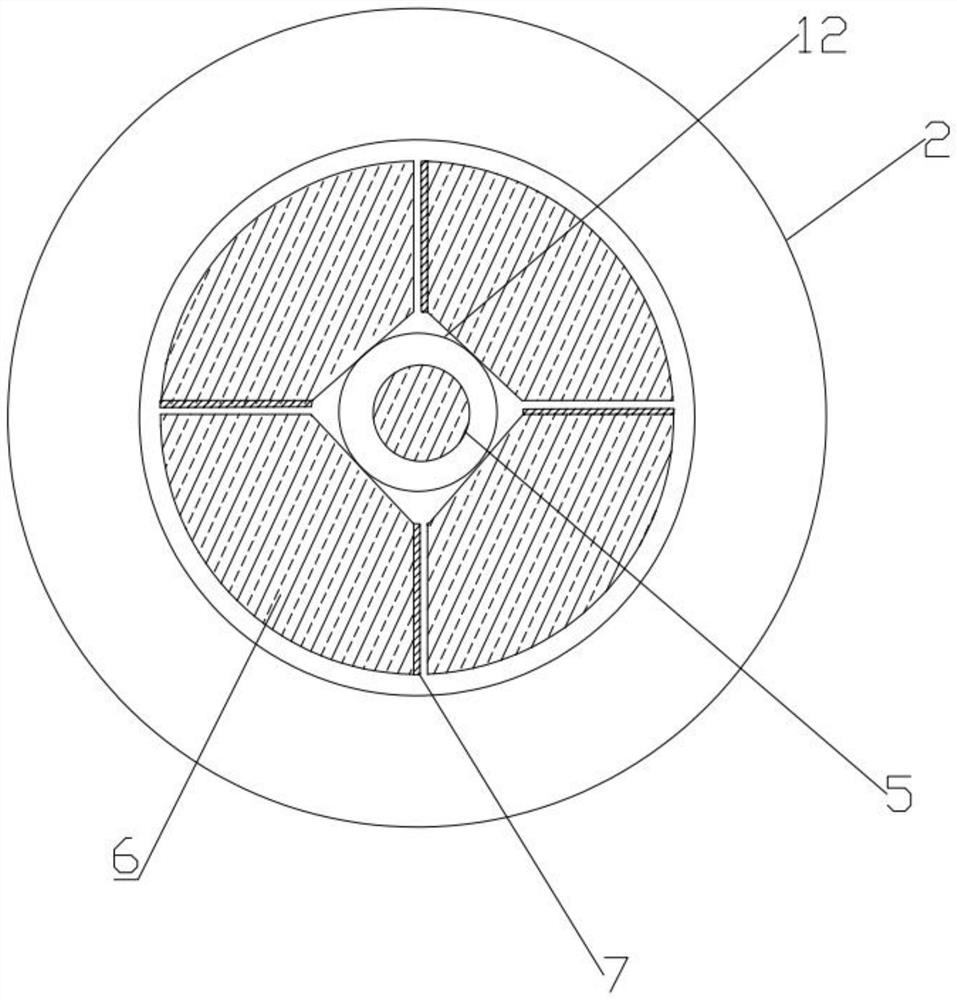

[0027] see figure 1 , the present invention relates to a fluid power capture and collection energy conversion device, the fluid power capture and collection energy conversion device includes a generator 1 and a buoy 2, the generator includes a stator and a rotor, in this device, the power generation The rotor of the machine is the rotating shaft 5, the buoy is fixed on the periphery of the generator, the buoy is fixed on the stator of the generator, one side of the buoy is provided with a tail rudder 3 in one direction, and the other side is provided with a rudder head 4, The tail rudder is fixed under the action of the water flow, and the buoy is always along the direction of the water flow, so that the buoy and the stator of the generator will not rotate with the rotor.

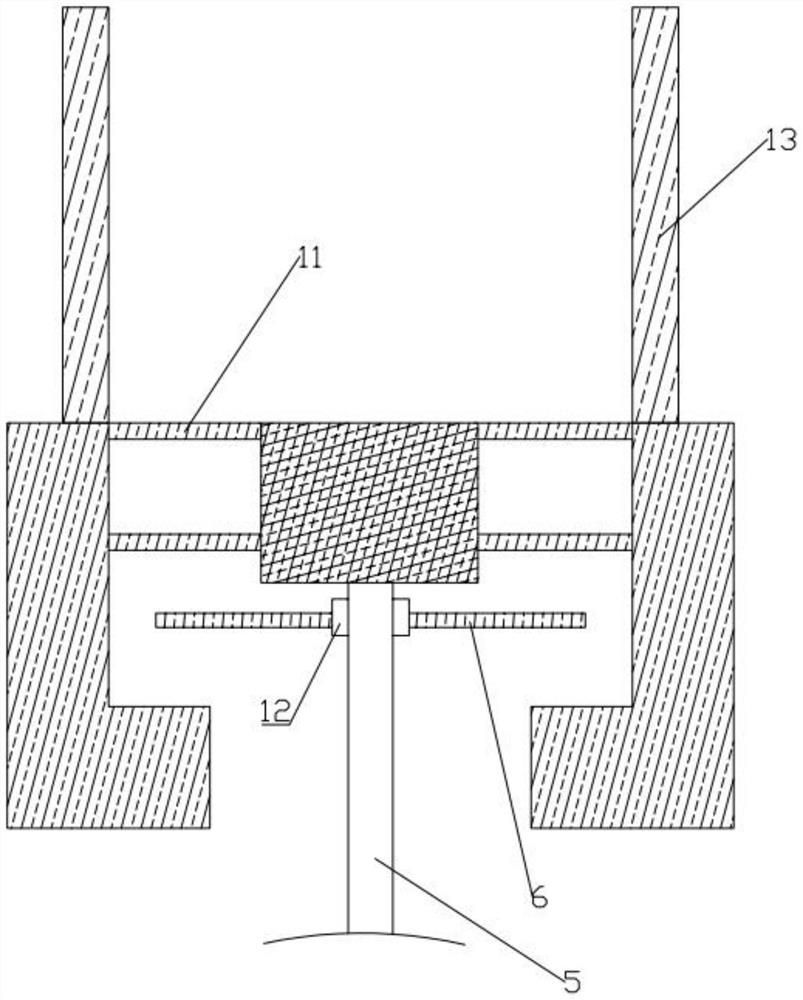

[0028] exist figure 2 and Figure 6 As shown, the float is connected to the generator through the mounting frame 11, and the generator is provided with mounting frames in four directions: up, down, left,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com