Solvent separation method of phytoextraction mixture

A solvent separation and mixture technology, applied in the field of plant extraction, can solve the problems of difficult collection and reuse, and achieve the effect of simple separation method, effective recovery of solvent, and easy reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

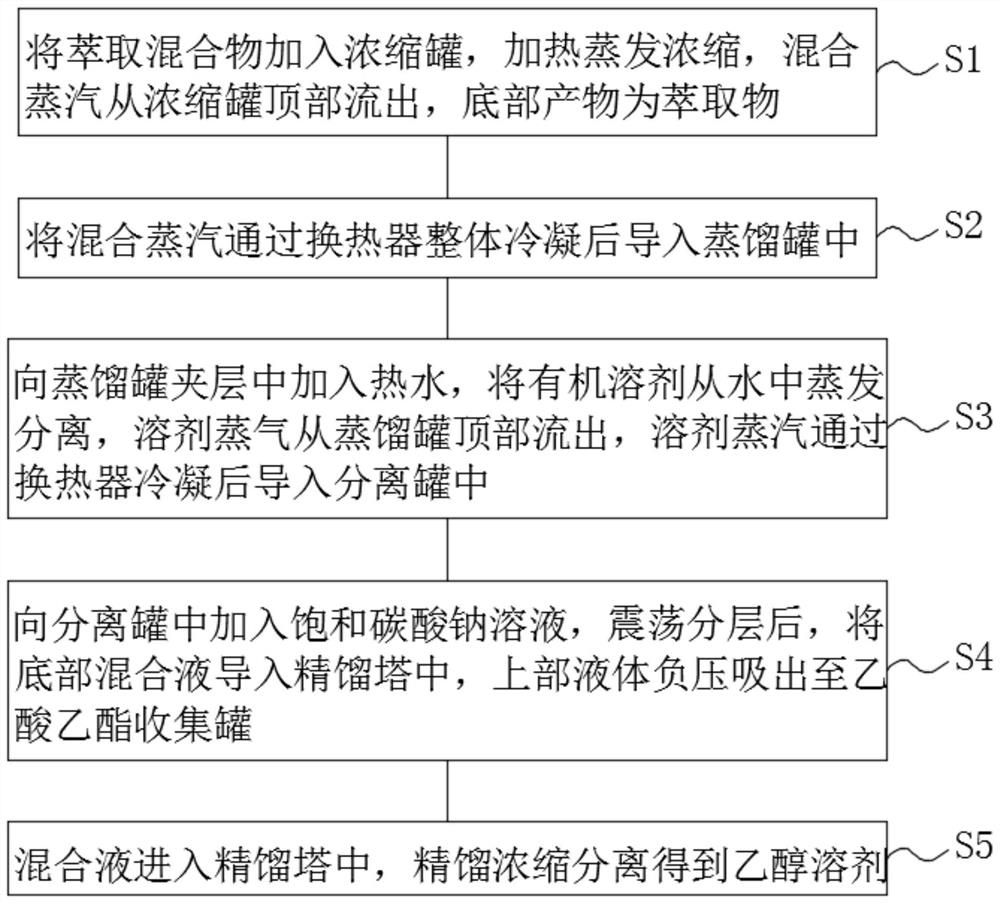

[0021] Example 1: Such as Figure 1 As shown, the present invention provides a solvent separation method for plant extraction mixtures, comprising the following steps:

[0022] S1, the overall evaporative concentration: the extraction mixture is added to the concentration tank, heated evaporation concentration, mixed steam flows out from the top of the concentration tank, and the bottom product is extractant;

[0023] S2, overall condensation: the mixed steam through the heat exchanger after the overall condensation into the distillation tank;

[0024] S3, distillation: add hot water to the sandwich of the distillation tank, evaporate and separate the organic solvent from the water, the solvent vapor flows out from the top of the distillation tank, and the solvent vapor is condensed through the heat exchanger and then introduced into the separation tank;

[0025] S4, solvent stratification: add saturated sodium carbonate solution to the separation tank, after the shock layering, t...

Embodiment 2

[0033] Example 2: Such as Figure 1 As shown, the present invention provides a solvent separation method for plant extraction mixtures, comprising the following steps:

[0034] S1, the overall evaporative concentration: the extraction mixture is added to the concentration tank, heated evaporation concentration, mixed steam flows out from the top of the concentration tank, and the bottom product is extractant;

[0035] S2, overall condensation: the mixed steam through the heat exchanger after the overall condensation into the distillation tank;

[0036] S3, distillation: add hot water to the sandwich of the distillation tank, evaporate and separate the organic solvent from the water, the solvent vapor flows out from the top of the distillation tank, and the solvent vapor is condensed through the heat exchanger and then introduced into the separation tank;

[0037] S4, solvent stratification: add saturated sodium carbonate solution to the separation tank, after the shock layering, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com