Method and equipment for immersion cleaning of ternary precursor

A technology for precursors and equipment, applied in the field of immersion and washing of ternary precursors, can solve problems such as raising production costs, and achieve the effects of reducing production costs, reducing costs, and reducing wastewater treatment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

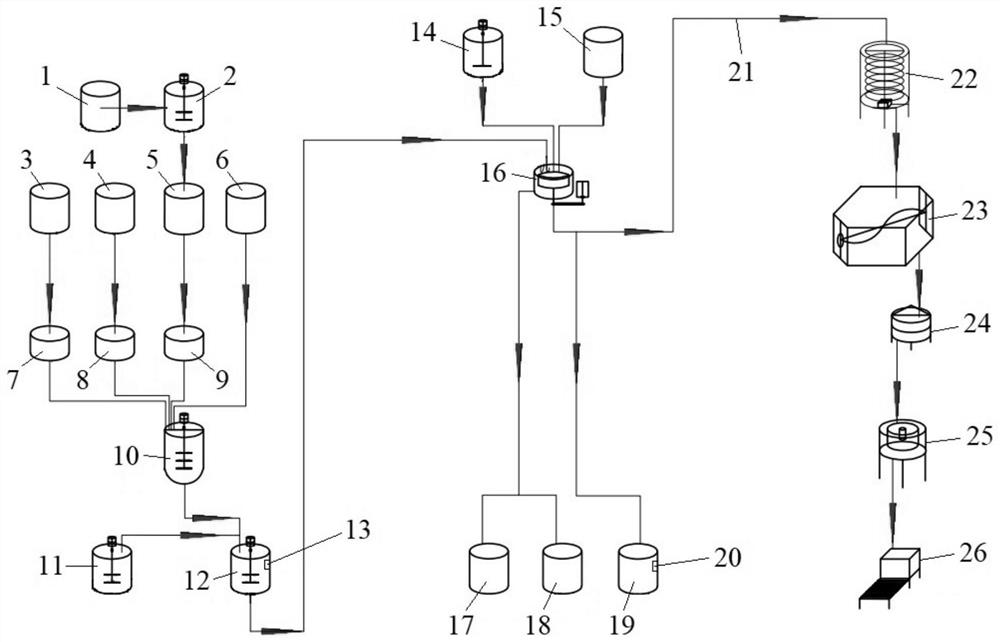

[0027] Such as figure 1 As shown, a device for immersing ternary precursors according to the present invention includes a first pure water tank 1, a feed liquid preparation tank 2, an ammonia water storage tank 3, a liquid alkali storage tank 4, a feed liquid storage tank 5, a first Second pure water tank 6, first balance tank 7, second balance tank 8, third balance tank 9, reaction kettle 10, first dilute alkali tank 11, aging tank 12, first ultrasonic vibrator 13, second dilute alkali Tank 14, third pure water tank 15, centrifuge 16, mother liquor tank 17, washing tank 18, pulping tank 19, second ultrasonic vibrator 20, conveyor belt 21, pan dryer 22, mixer 23, vibrating screen 24 , Iron remover 25 and packaging machine 26.

[0028] The first pure water tank 1 connects the feed liquid preparation tank 2, the feed liquid preparation tank 2 connects the feed liquid storage tank 5, and the feed liquid preparation tank 2 is used to prepare NCM (NiCoMn, nickel cobalt manganese) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com