Beverage canning device

A canning and beverage technology, which is applied in packaging, bottling machines, liquid bottling, etc., can solve the problems of sealing, manual canning, etc., and achieve the effect of reducing investment, reducing cost, low investment, and reducing the number of placements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

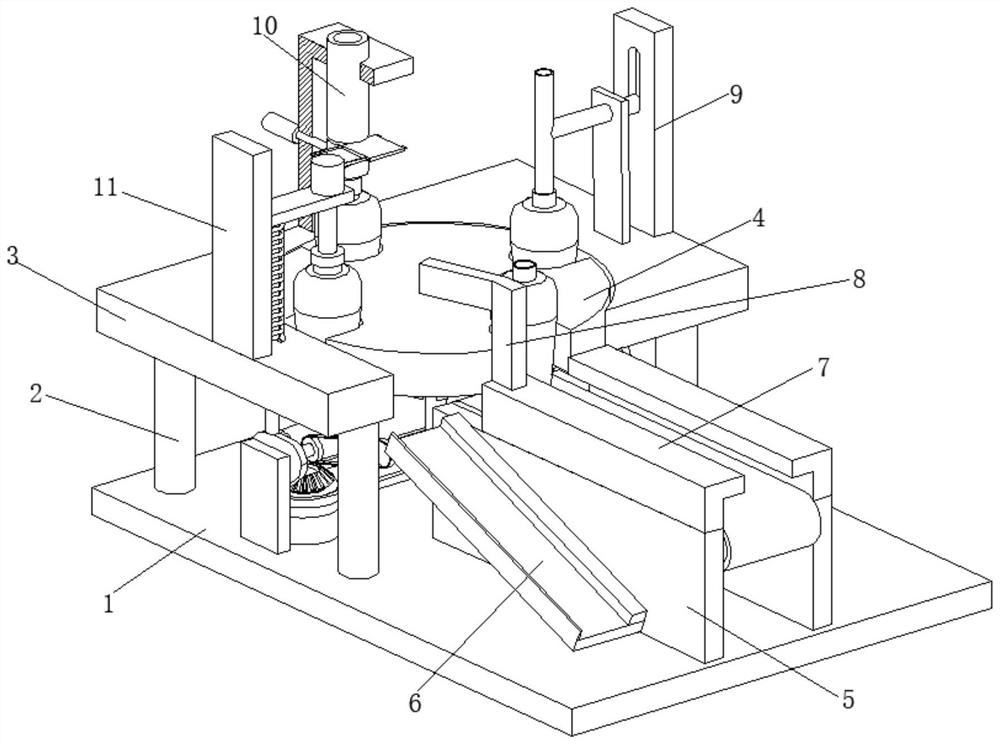

[0030] A beverage canning device, such as Figure 1-Figure 6 As shown, including the base 1, the top of the base 1 is welded with four support columns 2, the top of the support column 2 is welded with a support plate 3, the inner wall of the support plate 3 is provided with a feed mechanism 4, and the top of the base 1 is welded with two Fixed plate 5, and fixed plate 5 is positioned at the right side of support column 2, and the front portion of fixed plate 5 is welded with slide plate 6, and the top of fixed plate 5 is welded with limit plate 7, and the top of limit plate 7 is welded with dial plate 8, The top of the support plate 3 is respectively provided with a filling mechanism 9 , a placing mechanism 10 and a sealing mechanism 11 , and the placing mechanism 10 is located between the filling mechanism 9 and the sealing mechanism 11 .

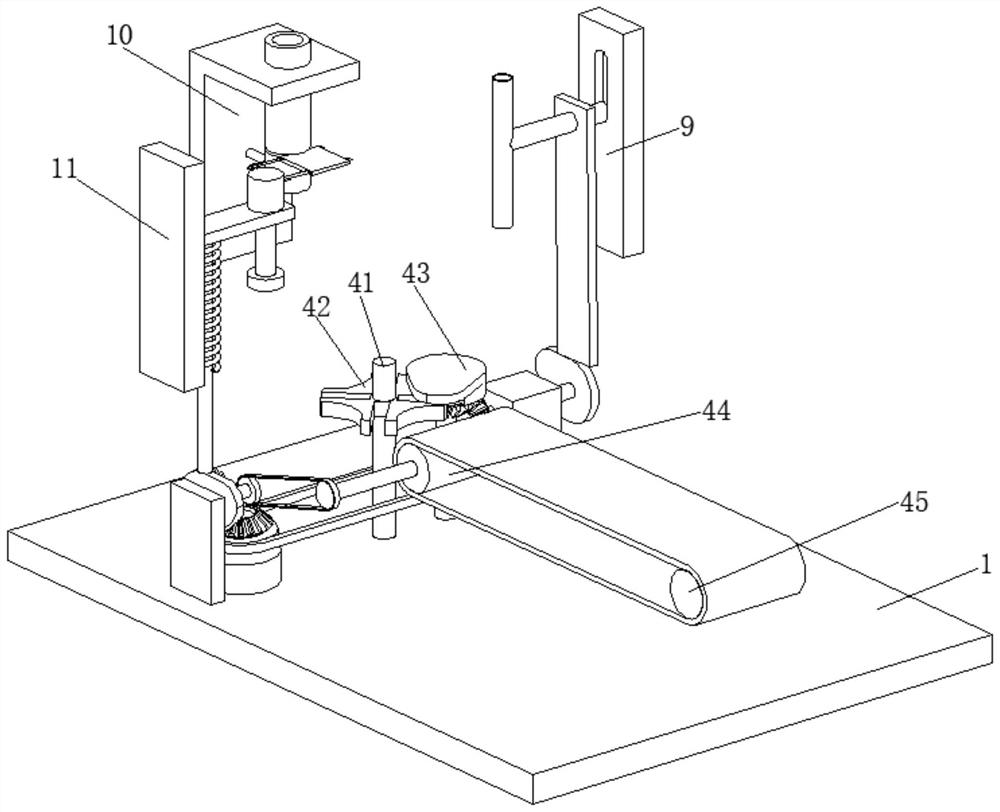

[0031] In this embodiment, the feed mechanism 4 includes a rotating shaft 41, the surface of the rotating shaft 41 is welded with a rotat...

Embodiment 2

[0041] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the bottom of the connecting block 101 is welded and fixed to the top of the support plate 3, and the output end of the electric push rod 106 is welded and fixed to the left side of the No. 2 pallet 104. The chute in the pipe 102 is not fully opened, it is only necessary to block the drop of the bottle cap when the No. 1 clamp 103 and the No. 2 clamp 104 are inserted.

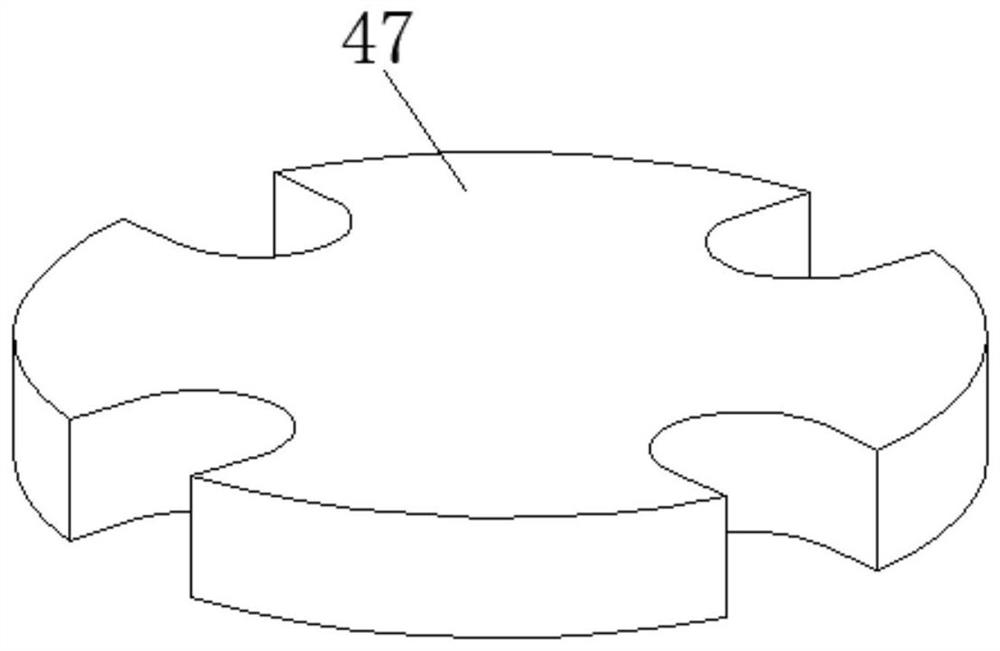

[0042] The sealing mechanism 11 includes a motor 111, the output end of the motor 111 is welded with a No. 1 pulley 112, the axis of the No. 1 pulley 112 is welded with a No. 3 bevel gear 113, and the surface of the No. 1 pulley 112 is driven by the surface of the belt and the No. 2 pulley 116. connection, the axis of the second pulley 116 is welded with a drive rod 117, the surface of the third bevel gear 113 is meshed with a fourth bevel gear 118, the axis of the fourth bevel gear 118 is welded with a third cam 119, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com