Washing-resistant alginate fiber and preparation method thereof

A seaweed fiber and washing-resistant technology, which is applied in fiber processing, textiles and papermaking, can solve the problems that affect the spinning effect and the spinning process is difficult to control, and achieve the effect of enhancing mechanical properties and washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] (1) Preparation of finishing solution:

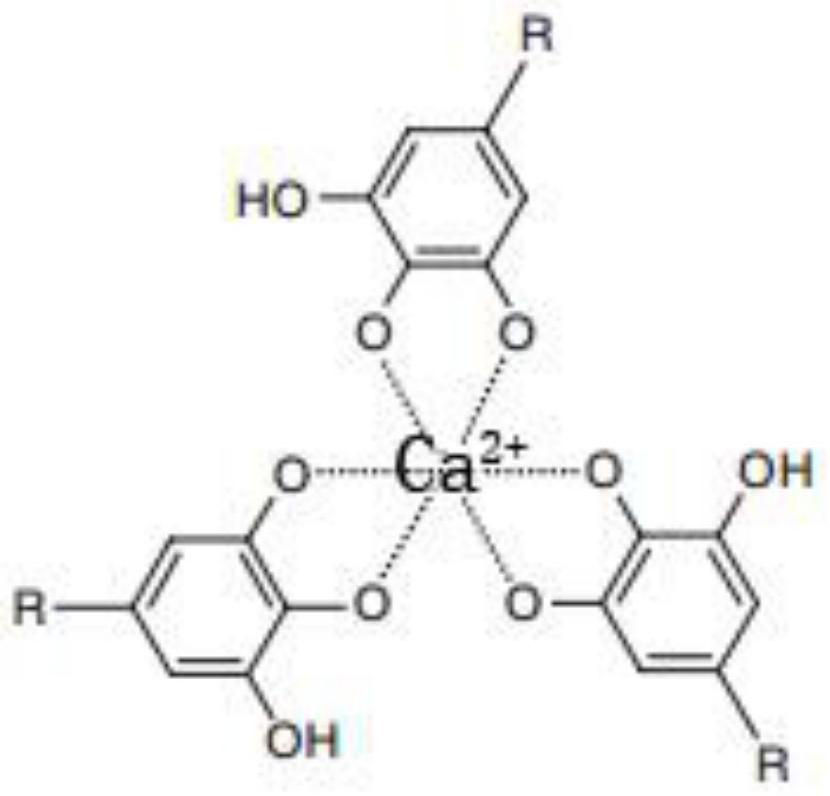

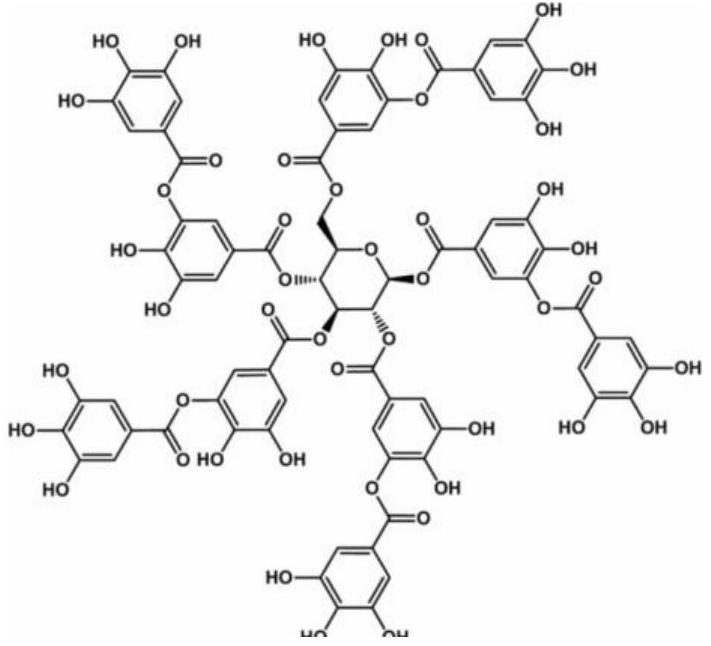

[0048] At room temperature, 1g of tannic acid was dissolved in 10wt% CaCl 2 In aqueous solution, heated to 45°C, with NaHCO concentration of 0.1035mol / L 3 The solution is used as a regulator to adjust the pH value of the finishing solution to 10;

[0049] (2) Preparation of washing-resistant seaweed fiber:

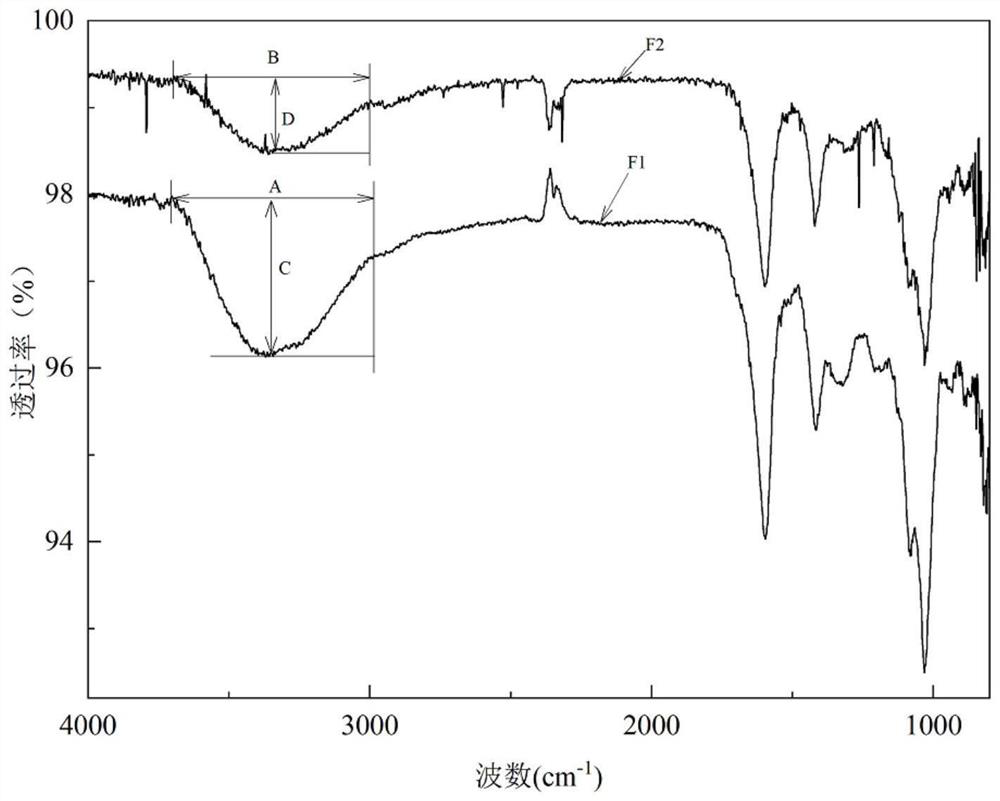

[0050] Immerse 10g of calcium alginate fibers in the finishing solution prepared in step (1) for 5 minutes. After taking it out, dry the finishing solution in the fiber, wash it repeatedly with water, and then dry it in an oven at 40°C. A washing-resistant seaweed fiber containing a five-membered ring chelate compound with a cross-linked network and a hydrogen bond cross-linked network structure is prepared. Its mechanical properties, swelling degree (soaked in NaCl solution) and alkali resistance (soaked in NaOH solution) data are shown in Table 1.

[0051] Table 1

[0052]

[0053] As can be seen from Table 1, compa...

Embodiment 2

[0055] (1) Preparation of finishing solution:

[0056] At room temperature, 1g of tannic acid was dissolved in 15wt% CaCl 2 In aqueous solution, heated to 25°C, with NaHCO concentration of 0.1697mol / L 3 The solution is used as a regulator to adjust the pH value of the finishing solution to 9;

[0057] (2) Preparation of washing-resistant seaweed fiber:

[0058] Immerse 5g of calcium alginate fibers in the finishing solution prepared in step (1) for 50 minutes. After taking it out, squeeze the finishing solution in the fibers to dry, wash them repeatedly with water, and then dry them in an oven at 45°C. A washing-resistant seaweed fiber containing a five-membered ring chelate compound with a cross-linked network and a hydrogen bond cross-linked network structure is prepared. Its mechanical properties, swelling degree (soaked in NaCl solution) and alkali resistance (soaked in NaOH solution) data are shown in Table 2.

[0059] Table 2

[0060]

[0061] As can be seen from...

Embodiment 3

[0063] (1) Preparation of finishing solution:

[0064] At room temperature, 3g of tannic acid was dissolved in 8wt% CaCl 2 In aqueous solution, heated to 55°C, with a concentration of 0.2047mol / L Na 2 CO 3 The solution is used as a regulator to adjust the pH value of the finishing solution to 9;

[0065] (2) Preparation of washing-resistant seaweed fiber:

[0066] Immerse 10g of calcium alginate fiber in the finishing solution prepared in step (1) for 200 minutes, after taking it out, squeeze the finishing solution in the fiber to dry, wash it repeatedly with water, and then dry it in an oven at 50°C. A washing-resistant seaweed fiber containing a five-membered ring chelate and a hydrogen bond crosslinked network is prepared. Its mechanical properties, swelling degree (soaked in NaCl solution) and alkali resistance (soaked in NaOH solution) data are shown in Table 3.

[0067] table 3

[0068]

[0069] It can be seen from Table 3 that the washing-resistant seaweed fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com