LED display device and preparation method and application thereof

A technology for display devices and light-emitting devices, applied in semiconductor devices, electrical components, coatings, etc., can solve the problems of long molding process cycle, single conductive modeling, unfavorable mass production, etc., and achieve industrial mass production, high thermal conductivity, etc. rate, reducing the effect of phonon scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] This embodiment is an LED display device and a manufacturing method thereof.

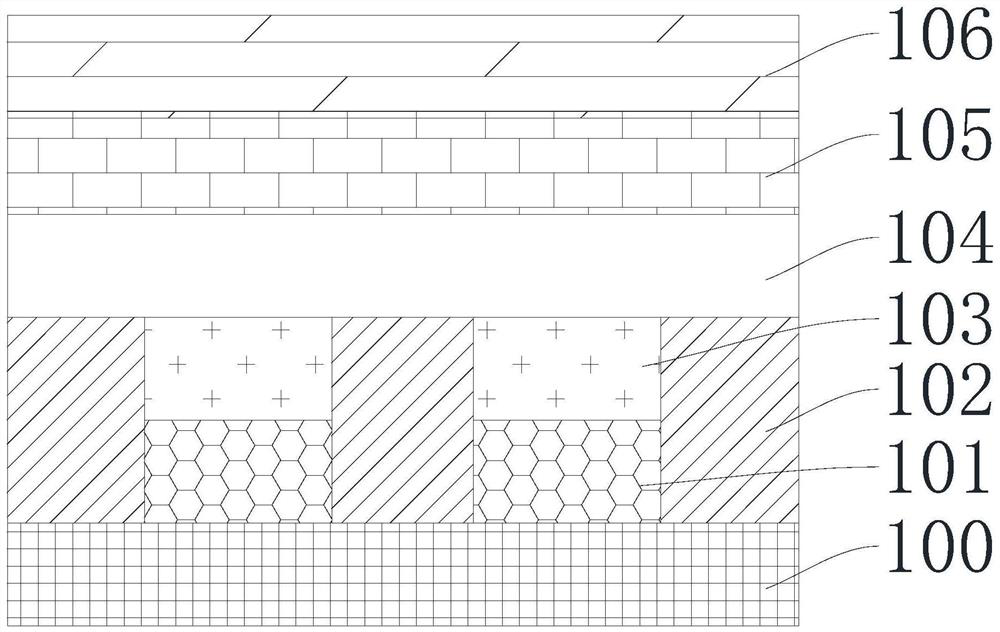

[0077] In this embodiment, the LED display device consists of figure 1 The structure shown consists of:

[0078] Including a driving circuit substrate 100;

[0079] Partial areas of the surface of the drive circuit substrate 100 are provided with electrode pins 101;

[0080] The surface of the electrode pin 101 is provided with an LED light emitting device 103;

[0081] The remaining area of the surface of the driving circuit substrate 100 is provided with a first heat dissipation layer 102;

[0082] A second heat dissipation layer 104 is provided on the surface of the first heat dissipation layer 102 and the surface of the LED light emitting device 103;

[0083] The surface of the second heat dissipation layer 104 is provided with a third heat dissipation layer 105;

[0084] The surface of the third heat dissipation layer 105 is provided with a fourth heat dissipation layer 106;

[0...

Embodiment 2

[0102] This embodiment is an LED display device and a manufacturing method thereof.

[0103] In this embodiment, the LED display device consists of figure 1 The structure shown consists of:

[0104] Including a driving circuit substrate 100;

[0105] Partial areas of the surface of the drive circuit substrate 100 are provided with electrode pins 101;

[0106] The surface of the electrode pin 101 is provided with an LED light emitting device 103;

[0107] The remaining area of the surface of the driving circuit substrate 100 is provided with a first heat dissipation layer 102;

[0108] A second heat dissipation layer 104 is provided on the surface of the first heat dissipation layer 102 and the surface of the LED light emitting device 103;

[0109] The surface of the second heat dissipation layer 104 is provided with a third heat dissipation layer 105;

[0110] The surface of the third heat dissipation layer 105 is provided with a fourth heat dissipation layer 106;

[0...

Embodiment 3

[0128] This embodiment is an LED display device and a manufacturing method thereof.

[0129] In this embodiment, the LED display device consists of figure 1 The structure shown consists of:

[0130] Including a driving circuit substrate 100;

[0131] Partial areas of the surface of the drive circuit substrate 100 are provided with electrode pins 101;

[0132] The surface of the electrode pin 101 is provided with an LED light emitting device 103;

[0133] The remaining area of the surface of the driving circuit substrate 100 is provided with a first heat dissipation layer 102;

[0134] A second heat dissipation layer 104 is provided on the surface of the first heat dissipation layer 102 and the surface of the LED light emitting device 103;

[0135] The surface of the second heat dissipation layer 104 is provided with a third heat dissipation layer 105;

[0136] The surface of the third heat dissipation layer 105 is provided with a fourth heat dissipation layer 106;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com