A kind of mxene/metal composite airgel, its preparation method, application and thermal interface material comprising it

A composite airgel and metal composite technology, applied in the field of thermally conductive materials, can solve problems such as limited thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

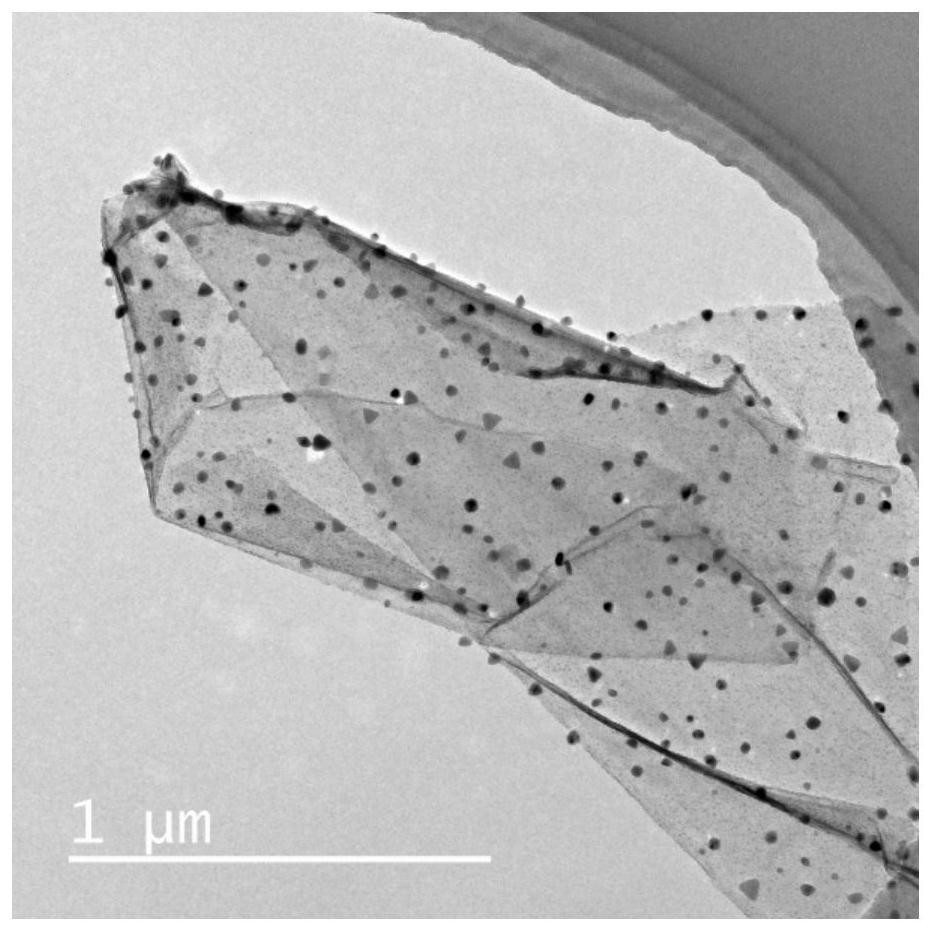

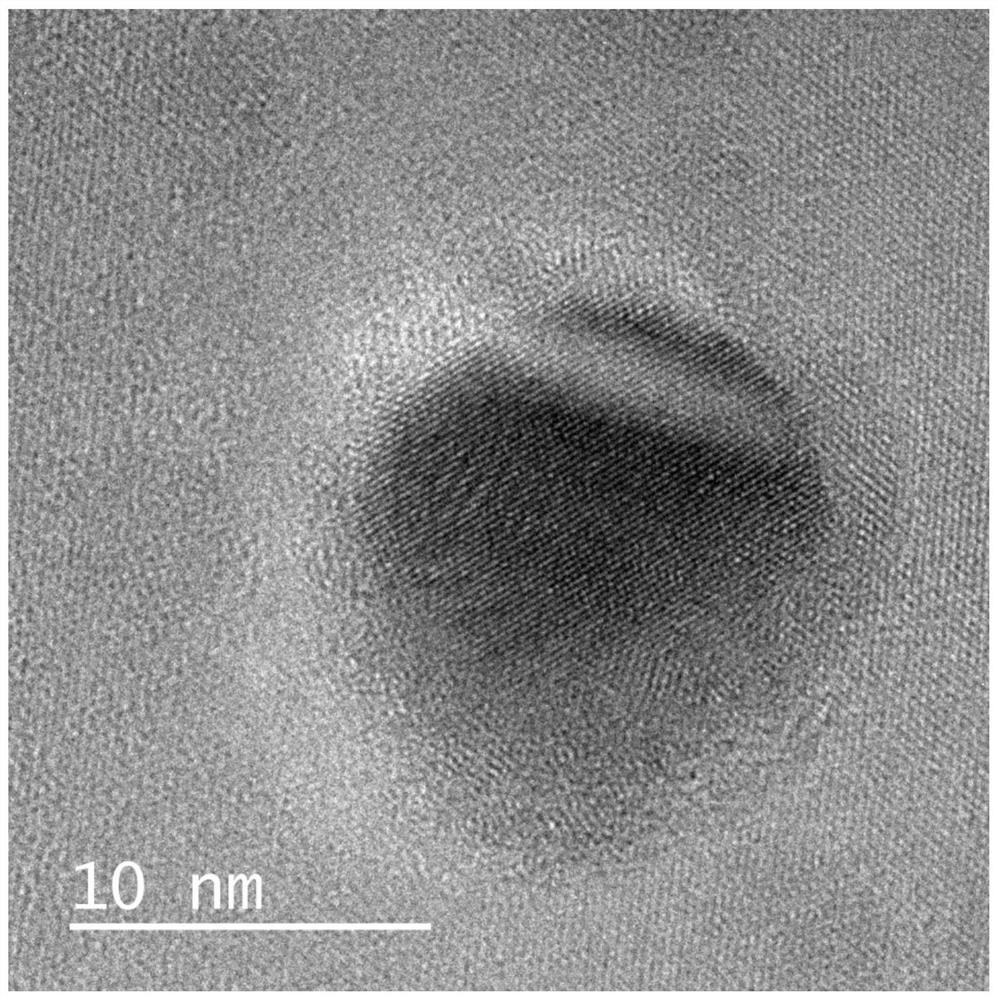

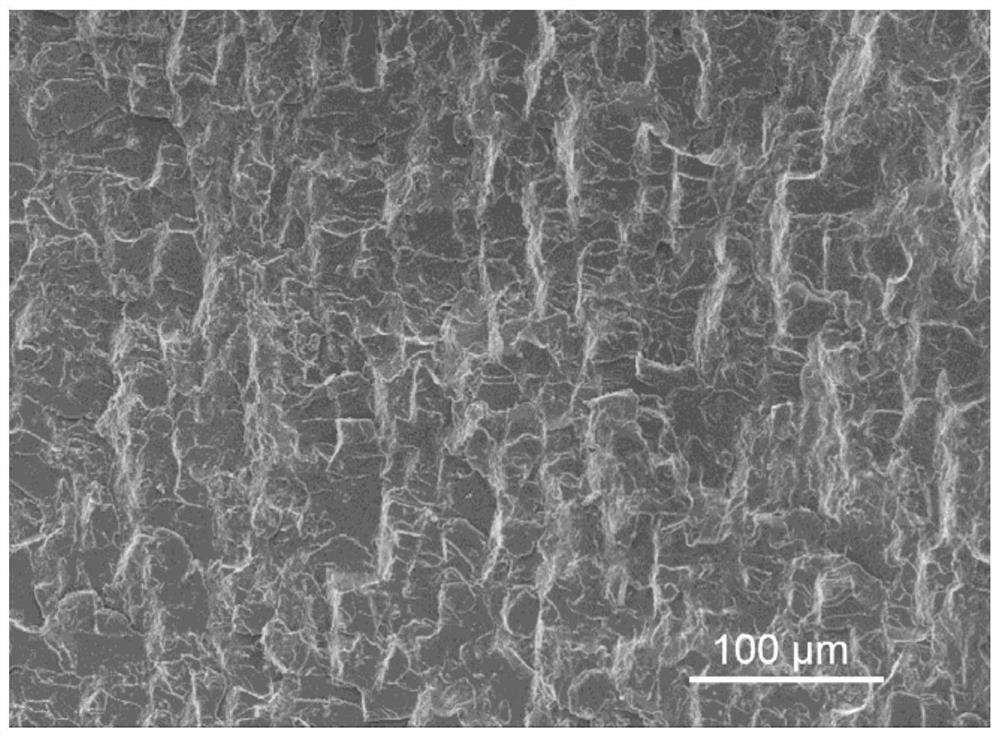

[0057] This embodiment provides an MXene / silver composite airgel, which includes an MXene skeleton and silver, and the MXene skeleton is cross-linked by silver to form a network structure.

[0058] Concrete preparation method is as follows:

[0059] (1) Dissolve 2g of lithium fluoride in 20mL of hydrochloric acid (9mol / L), then 2g of MAX(Ti 3 AlC 2 ) powder into the above solution, stirred at room temperature for 24 hours for etching, the etched sample was washed and collected by centrifugation, then dispersed in deionized water, mechanically shaken for 5 minutes, centrifuged at 3500 rpm for 30 minutes, collected Clear liquid, namely MXene(Ti 3 C 2 ) dispersion (concentration of about 0.7mg / mL);

[0060] (2) Take 200mL of the MXene dispersion obtained in step (1), drop 1mL of silver nitrate solution with a concentration of 0.5mol / L, and after fully stirring, ultrasonically vibrate the mixture in an ice bath for 30 minutes to reduce the silver ions Form silver nanoparticle...

Embodiment 2

[0065] This embodiment provides an MXene / silver composite airgel, which includes an MXene skeleton and silver, and the MXene skeleton is cross-linked by silver to form a network structure.

[0066] Concrete preparation method is as follows:

[0067] (1) Dissolve 2g of lithium fluoride in 20mL of hydrochloric acid (9mol / L), then 2g of MAX(Ti 2 AlC) powder was added to the above solution, stirred at room temperature for 24 hours for etching, the etched sample was washed and collected by centrifugation, then dispersed in deionized water, mechanically shaken for 5 minutes, centrifuged at 3500 rpm for 30 minutes, collected The supernatant is MXene(Ti 2 C) dispersion liquid;

[0068] (2) Take 200mL of the MXene dispersion obtained in step (1), drop 1mL of silver nitrate solution with a concentration of 1mol / L, and after fully stirring, ultrasonically vibrate the mixture in an ice bath for 30 minutes to reduce the silver ions to Silver nanoparticles are centrifuged to remove the s...

Embodiment 3

[0072]This embodiment provides an MXene / silver composite airgel, which includes an MXene skeleton and silver, and the MXene skeleton is cross-linked by silver to form a network structure.

[0073] Concrete preparation method is as follows:

[0074] (1) Dissolve 2g lithium fluoride in 20mL hydrochloric acid (9mol / L), then 2g MAX (V 2 AlC) powder was added to the above solution, stirred at room temperature for 24 hours for etching, the etched sample was washed and collected by centrifugation, then dispersed in deionized water, mechanically shaken for 5 minutes, centrifuged at 3500 rpm for 30 minutes, collected The supernatant is MXene (V 2 C) dispersion liquid;

[0075] (2) Take 200mL of the MXene dispersion obtained in step (1), drop 1mL of silver nitrate solution with a concentration of 2mol / L, and after fully stirring, ultrasonically vibrate the mixture in an ice bath for 30 minutes to reduce the silver ions to Silver nanoparticles are centrifuged to remove the supernatant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com