Anti-splashing pin shearing equipment for processing pins of electronic integrated circuit board

An integrated circuit, anti-splash technology, applied in the field of anti-splash foot clipping equipment, can solve the problems of poor pin restriction, scratched circuit boards, poor environmental protection, etc., to improve environmental protection and reliability, secure contact, avoid pin splash effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

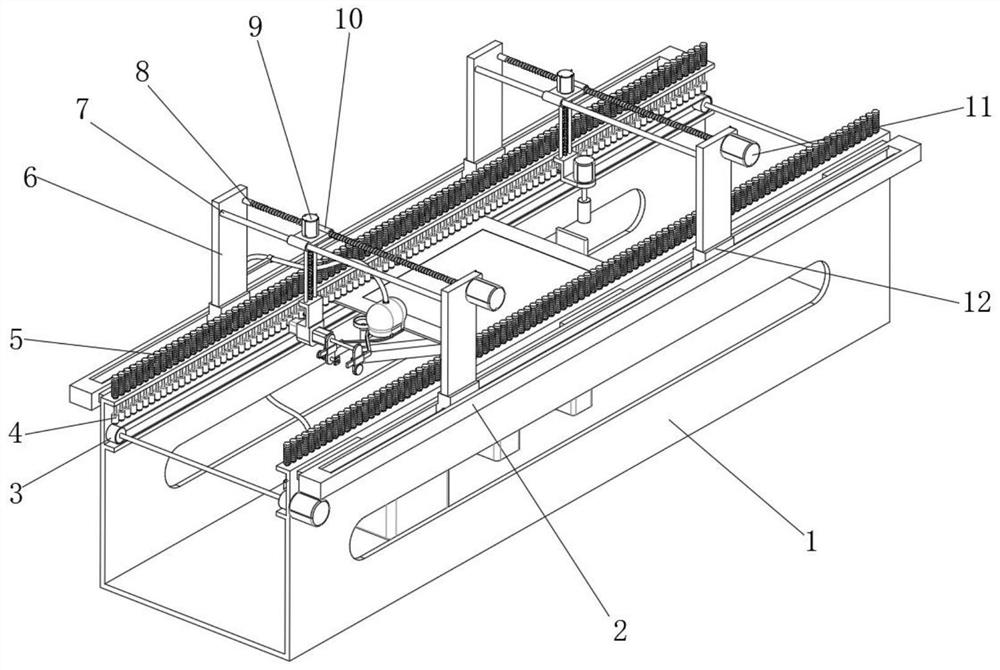

[0088] An anti-splash pin cutting device for pin processing of electronic integrated circuit boards, such as Figure 1-8 shown, including:

[0089] Conveying platform 1, the outer walls of both sides of the top of the conveying platform 1 are fixed with electric moving rails 2;

[0090] Conveyor belt 3, the conveyor belt 3 is installed on the inner walls of both sides of the conveyor table 1;

[0091] Circuit board carrier 13, circuit board carrier 13 is placed on conveyor belt 3 top, is used for installing and carrying the circuit board to be cut off;

[0092] A mobile adjustment mechanism, the mobile adjustment mechanism is installed on two electric moving rails 2;

[0093] Foot cutting mechanism, the foot cutting mechanism is installed on a mobile adjustment mechanism;

[0094] Grinding mechanism, the grinding mechanism is installed on another mobile adjustment mechanism;

[0095] Wherein, the foot cutting mechanism includes:

[0096] The first mounting frame 29, the f...

Embodiment 2

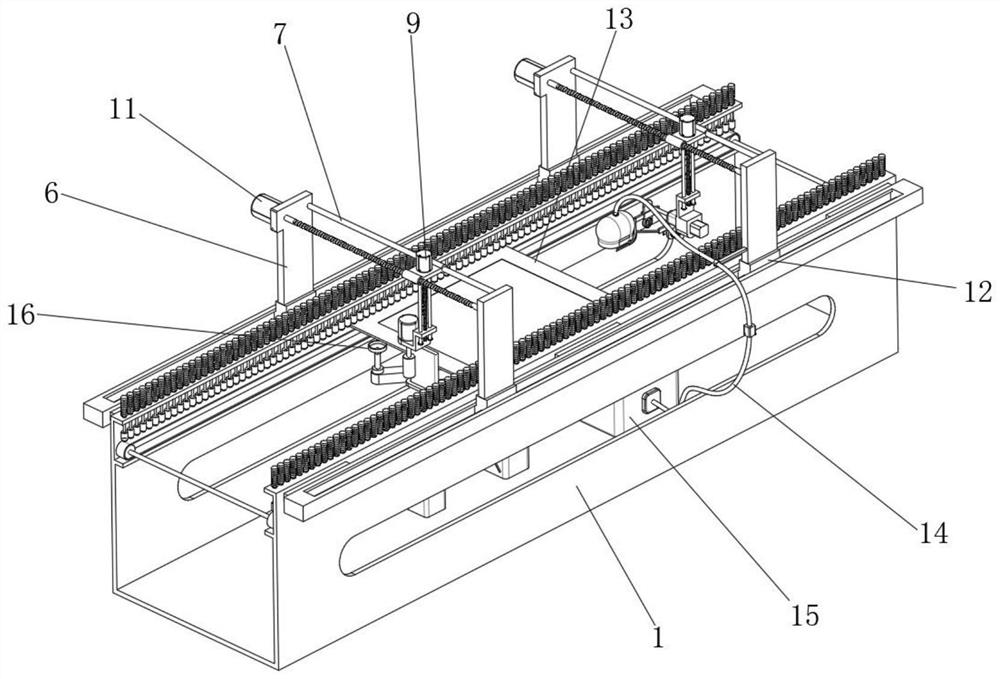

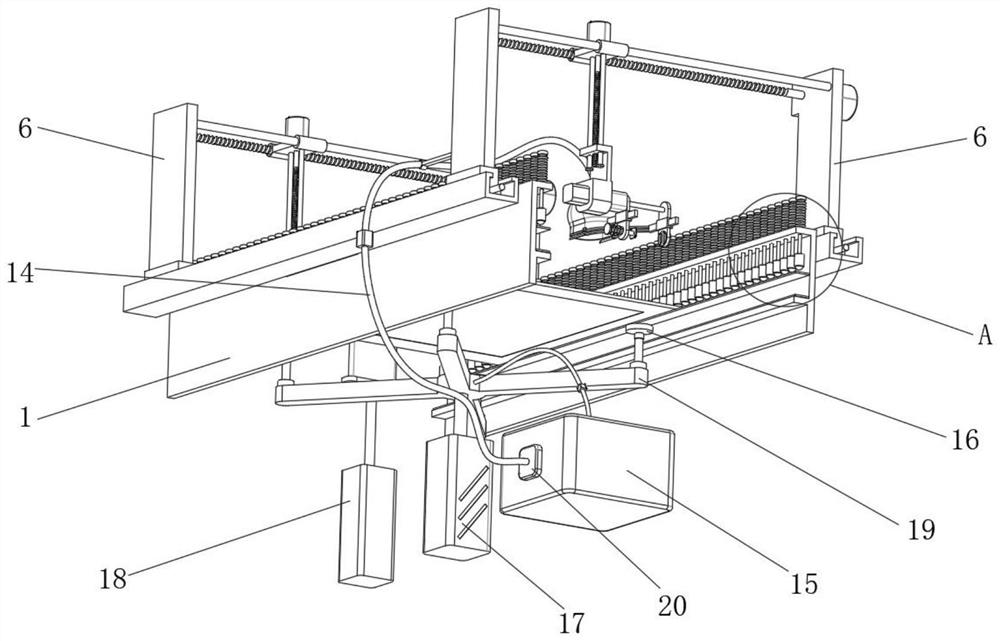

[0149] An anti-splash pin cutting device for pin processing of electronic integrated circuit boards, such as figure 2 , image 3 , Figure 6 As shown, in order to improve the positioning effect of the circuit board and the circuit board carrier 13; this embodiment makes the following improvements on the basis of embodiment 1: a negative pressure fixing mechanism is installed on the conveying table 1, and the negative pressure fixing Agencies include:

[0150] The second electric telescopic cylinder 17, the second electric telescopic cylinder 17 is fixed on the bottom inner wall of the conveying table 1 by screws;

[0151] Jacking frame 19, the jacking frame 19 is fixed on the output end of the second electric telescopic cylinder 17, and the jacking frame 19 is a hollow structure;

[0152] Suction cup 16, the suction cup 16 is fixed on the top four corners of the jacking frame 19;

[0153] The second negative pressure generating device 28, the second negative pressure gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com