Gas chromatography system and method for detecting detailed composition of automotive gasoline

A technology for detecting cars and gasoline, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as large deviations in quantitative results, and achieve the effect of compact system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

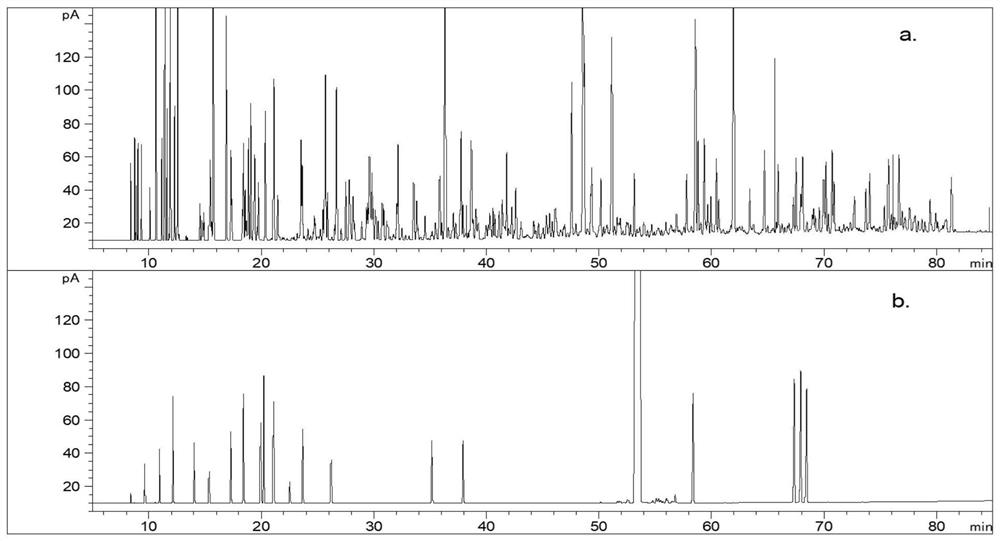

[0051] According to a specific embodiment of the present invention, the method may also include: according to the retention time or retention index of the chromatographic peak in the first chromatogram, compare it with the retention time or retention index of the components in the known database, identify The chromatographic peak in the first chromatogram, that is, to qualitatively identify the chromatographic peak and determine the difficult-to-separate components in the gasoline sample to be tested.

[0052] Exemplarily, in the first chromatogram, according to the chromatographic retention time or retention index, compared with the known qualitative database, 2,3,3-trimethylpentane and toluene have the same retention time, and the two are co-eluting Difficult to separate components.

[0053] According to one embodiment of the present invention, within a preset period of time, the target difficult-to-separate components in the continuous effluent components are sequentially e...

Embodiment approach

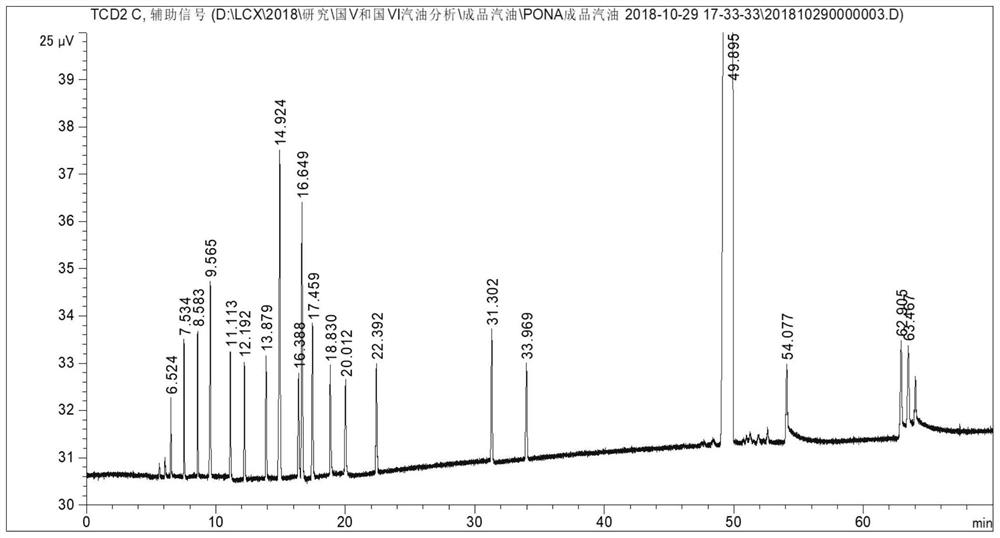

[0055] According to an embodiment of the present invention, the method may include: determining a preset time period. For example, a standard sample containing difficult-to-separate components is used to determine the preset time period.

[0056] Exemplary embodiment: prepare the alkane solution containing the target difficult-to-separate component as a standard sample, or take the actual typical gasoline sample containing the target difficult-to-separate component as the standard sample, and make the standard sample flow into the second nonpolar column, damping The column and the second detector are used to obtain the second chromatogram; the preset time period is determined according to the second chromatogram; wherein, the chromatographic column resistance of the damping column is equal to the chromatographic resistance of the polar chromatographic column.

[0057] In a further embodiment, the standard sample can also contain a reference substance, which is a component that...

Embodiment 1

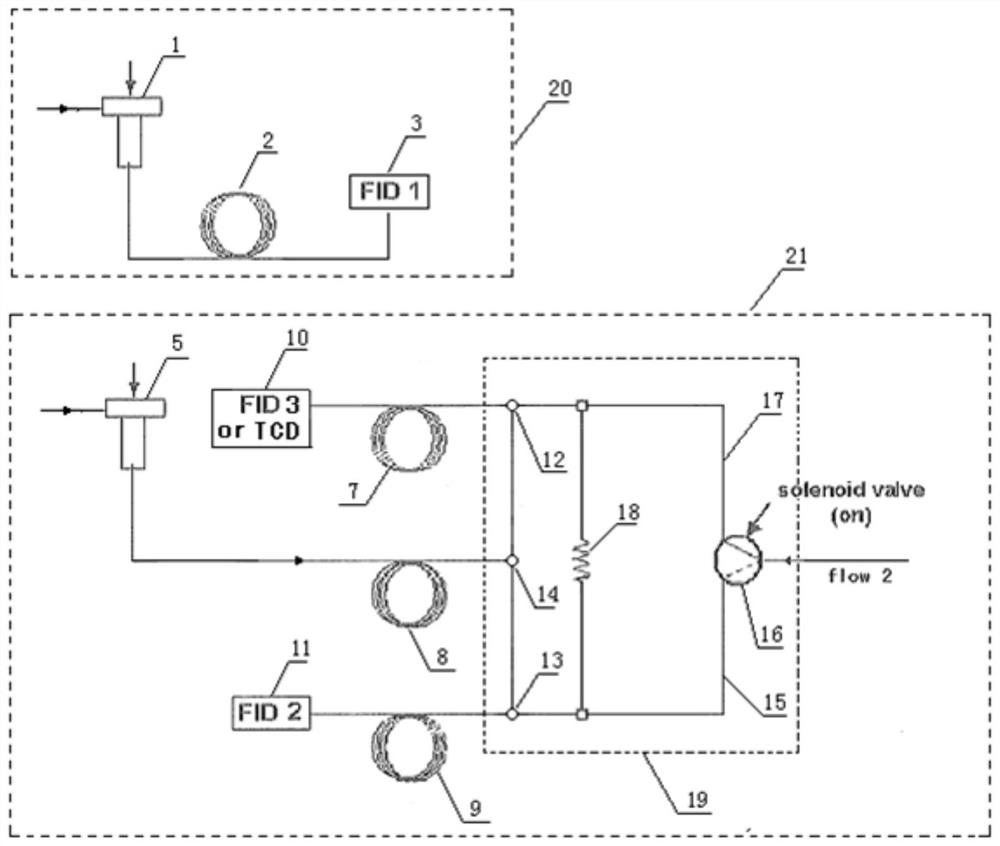

[0077] The structure of the present embodiment gas chromatograph system is as follows:

[0078] Such as figure 1 As shown, the first detection channel 20 comprises a first sample inlet 1, a first non-polar chromatographic column 2 (the HP-PONA chromatographic column of Agilent Company, the stationary phase is 100% methylpolysiloxane, and the column length is 50m , inner diameter of 0.20mm), hydrogen flame ionization detector. The inlet of the first non-polar chromatographic column 2 communicates with the first sample inlet 1, and the outlet of the first non-polar chromatographic column 2 communicates with the inlet of the first hydrogen flame ionization detector.

[0079] The second detection channel 21 comprises a second sample inlet 5, a second non-polar chromatographic column 8 (the HP-PONA chromatographic column of Agilent Corporation, the stationary phase is 100% methyl polysiloxane, the column length is 50m, and the inner diameter is 0.20mm), center cutting assembly 19...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com