Processing technology of high-strength AZ91D alloy material

An alloy material and processing technology, applied in the field of high-strength AZ91D alloy material processing technology, can solve the problems of easy oxidation during storage, poor impact resistance and tensile strength, etc., and achieve quality reduction, extended service life, and damage resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

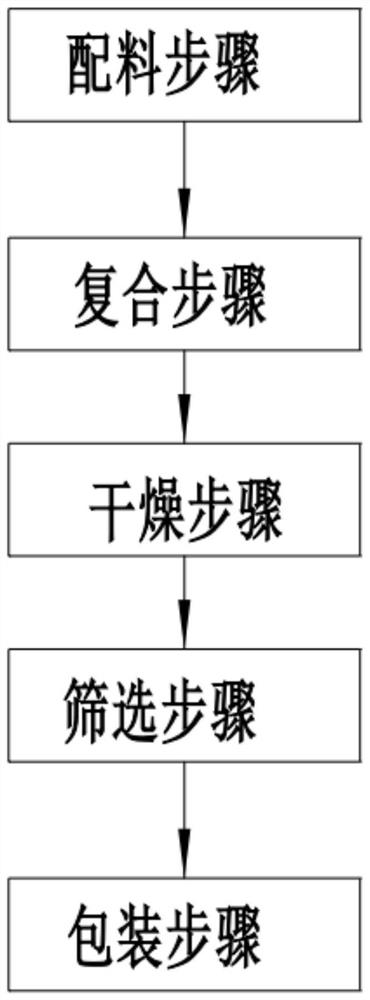

[0032] A high-strength AZ91D alloy material processing technology, comprising the following steps:

[0033] Ingredients step: preparing graphene powder, magnesium alloy powder material and attapulgite clay powder;

[0034] Composite step: composite the graphene powder, magnesium alloy powder and attapulgite clay powder in the batching step with a vertical ball mill to obtain a composite powder material;

[0035] Drying step: drying the composite powder;

[0036] Screening step: screening the dried composite powder;

[0037] Packaging step: packaging the screened composite powder.

[0038] Further, in the compounding step, the graphene powder is a graphene material with 1-10 layers.

[0039] Further, in the batching step, the mass proportion of graphene powder is 4%, the mass proportion of magnesium alloy powder material is 95%, and the mass proportion of attapulgite clay powder is 1%.

[0040] Further, in the batching step, the magnesium alloy powder material includes AZ91...

Embodiment 2

[0048] A high-strength AZ91D alloy material processing technology, comprising the following steps:

[0049] Ingredients step: preparing graphene powder, magnesium alloy powder material and attapulgite clay powder;

[0050] Composite step: composite the graphene powder, magnesium alloy powder and attapulgite clay powder in the batching step with a vertical ball mill to obtain a composite powder material;

[0051] Drying step: drying the composite powder;

[0052] Screening step: screening the dried composite powder;

[0053] Packaging step: packaging the screened composite powder.

[0054] Further, in the compounding step, the graphene powder is a graphene material with 1-10 layers.

[0055]Further, in the batching step, the mass proportion of graphene powder is 8%, the mass proportion of magnesium alloy powder material is 87%, and the mass proportion of attapulgite clay powder is 10%.

[0056] Further, in the batching step, the magnesium alloy powder material includes AZ91...

Embodiment 3

[0064] A high-strength AZ91D alloy material processing technology, comprising the following steps:

[0065] Ingredients step: preparing graphene powder, magnesium alloy powder material and attapulgite clay powder;

[0066] Composite step: composite the graphene powder, magnesium alloy powder and attapulgite clay powder in the batching step with a vertical ball mill to obtain a composite powder material;

[0067] Drying step: drying the composite powder;

[0068] Screening step: screening the dried composite powder;

[0069] Packaging step: packaging the screened composite powder.

[0070] Further, in the compounding step, the graphene powder is a graphene material with 1-10 layers.

[0071] Further, in the batching step, the mass proportion of graphene powder is 12%, the mass proportion of magnesium alloy powder material is 83%, and the mass proportion of attapulgite clay powder is 10%.

[0072] Further, in the batching step, the magnesium alloy powder material includes AZ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com