Composite layer resistant to damp-heat aging as well as preparation method and application of composite layer

A composite layer and moisture-resistant technology, which is applied in chemical instruments and methods, applications, and other household appliances, can solve the problems of complicated and lengthy preparation procedures, complicated preparation processes, and complex functional layer structures of multi-layer laminated structures, and achieve superior durability. Humid heat aging performance, excellent tensile strength, and low implementation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preferably, this embodiment proposes a method for preparing a composite layer resistant to moisture and heat aging as described above. The dip-melt composite molding process includes at least the following steps:

[0034] S10), coating the thermoplastic polymer on the fiber fabric layer by film impregnation or powder impregnation or electrostatic fluidized bed impregnation to obtain a pre-impregnated composite layer; it should be noted that the film impregnation or powder impregnation or electrostatic fluidized bed impregnation involved in this application The fluidized bed impregnation method is a conventional impregnation process used in the field of composite materials. Specifically, film impregnation usually refers to heating the thermoplastic polymer to a molten state, and impregnating the fiber fabric layer in the molten thermoplastic polymer; powder impregnation It refers to coating the powdery thermoplastic polymer on the fiber fabric layer by spraying or brushin...

Embodiment 1

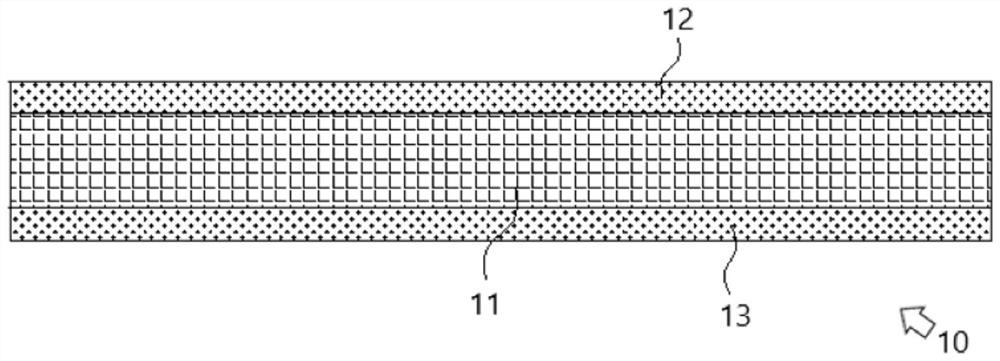

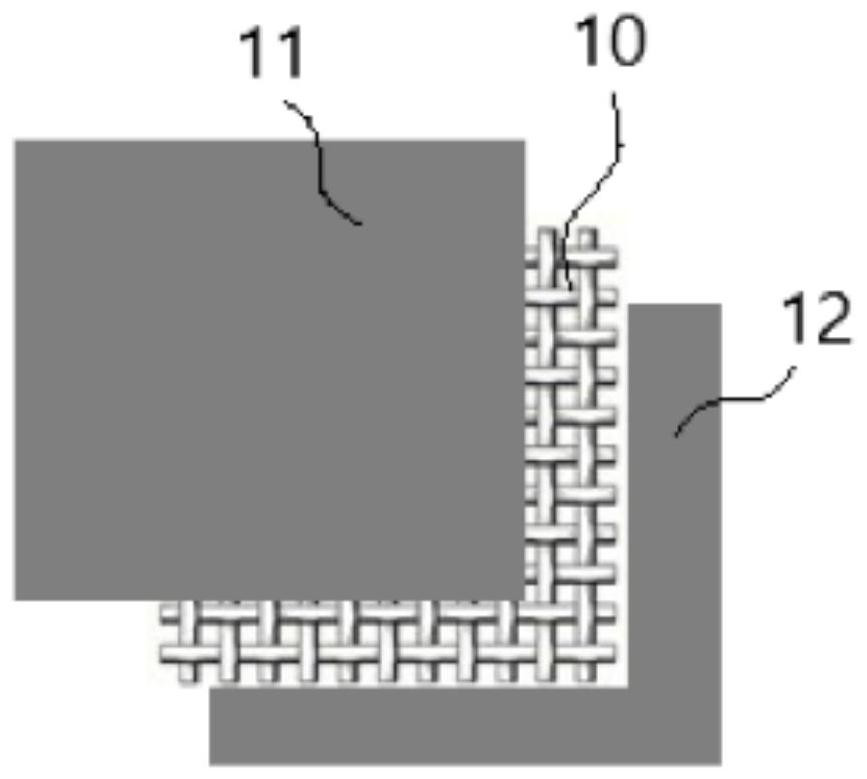

[0041] Example 1: see figure 1 and figure 2 As shown, a composite layer 10 resistant to moisture and heat aging includes a fiber fabric layer 11, and a first thermoplastic film layer 12 and a second thermoplastic film layer 13 compounded on the upper and lower surfaces of the fiber fabric layer 11, wherein each The thermoplastic film layers 12, 13 are combined on the upper and lower surfaces of the fiber fabric layer 11 by dipping and melting composite molding process, each thermoplastic film layer 12, 13 is made of polypropylene, and the fiber fabric layer 11 is made of glass fiber, in a twill shape.

[0042] During preparation, polypropylene is coated on the fiber fabric layer 11 by film impregnation to obtain a pre-impregnated composite layer; then the pre-impregnated composite layer is heated and pressurized by a rolling laminating machine at a heating temperature of 200-220°C, The pressing pressure is 0.1-0.25Mpa; the molten polypropylene is extruded on the fiber fabric...

Embodiment 2

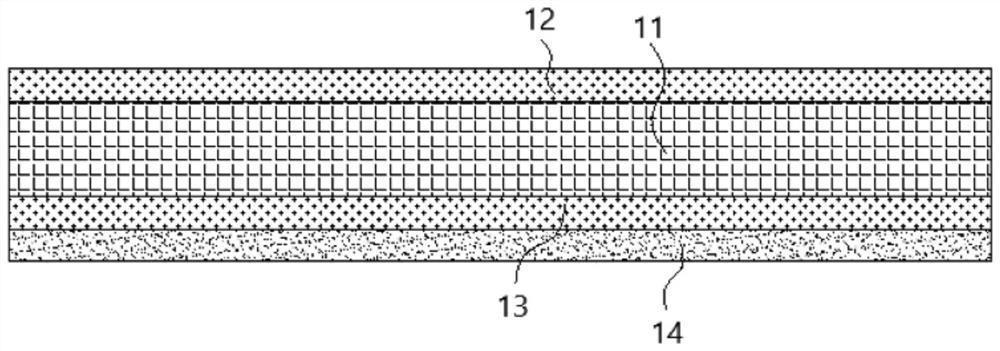

[0045] Embodiment 2: The remaining technical solutions of this embodiment 2 are the same as those of embodiment 1, the difference is that in this embodiment 2, please refer to image 3 As shown, the surface of the composite layer 10 in Example 1 is corona treated, and then the outer surface of the second thermoplastic film layer 13 is further coated with a fluorocarbon weather-resistant coating 14 .

[0046] After testing, in the composite layer obtained in the present embodiment 2, the tensile strength is 200MPa, the shrinkage rate is 0%, and the tensile strength attenuation after PCT aging is 35%; the barrier water vapor permeability is 0.21g / (m 2 24h).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com