Prepreg prepared from boron nitride modified by continuous method and high-thermal-conductivity thermosetting high-frequency copper-clad plate

A prepreg, boron nitride technology, applied in the field of communication materials, can solve problems such as poor thermal conductivity and heat dissipation, and achieve the effects of reducing environmental protection pressure, reducing production costs, and improving bending strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

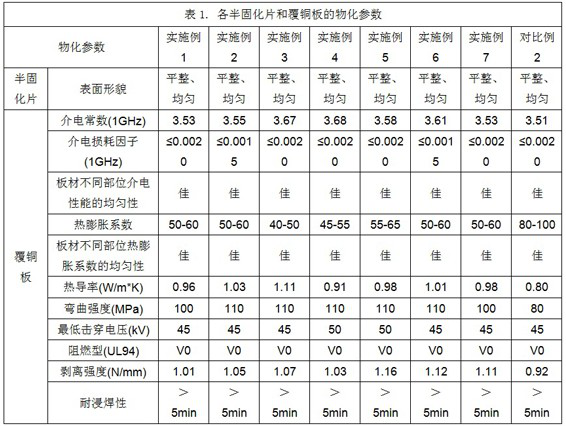

Image

Examples

Synthetic example 1

[0055] Take 120 parts of boron nitride (BN, D50=10um) and mix it in 3500 parts of pure water. After ball milling and dispersing for 30 minutes, add 70 parts of NaOH to it. After 8 hours of ultrasound-assisted reaction at 80°C, add acetic acid to adjust the pH Values between 6-7 give a homogeneous dispersion of activated boron nitride.

[0056] Configuration 2wt%H 2 100 parts of O / ethanol mixed solution, add 0.7 parts of coupling agent KH550 and 2.3 parts of coupling agent KH570, after stirring at 55°C for 5 minutes, adjust the pH value of the system to between 3-5, and continue stirring for 15 minutes to obtain Activated coupling reagent solution.

[0057] Pour the activated coupling agent solution into the uniform dispersion of activated boron nitride, continue to stir at 60°C for 4 hours, filter and wash the product with water several times until the pH value of the filtrate is between 7-8 ; Finally, after the filter cake was rinsed with ethanol and toluene in turn, the ...

Synthetic example 2

[0060] Take 120 parts of BN (D50=20um) and mix them in 3500 parts of pure water. After ball milling and dispersing for 30 minutes, add 80 parts of NaOH to it. After 12 hours of ultrasound-assisted reaction at 80°C, add acetic acid to adjust the pH value at 6- 7, a uniform dispersion of activated boron nitride was obtained.

[0061] Configuration 2wt%H 2 100 parts of O / ethanol mixed solution, add 0.8 parts of coupling agent KH550 and 3.5 parts of coupling agent KH570, stir at 50°C for 10 minutes, adjust the pH value of the system to between 3-5, and continue stirring for 20 minutes to obtain Activated coupling reagent solution.

[0062] Pour the activated coupling agent solution into the uniform dispersion of activated boron nitride, continue to stir at 60°C for 5 hours, filter and wash the product with water several times until the pH value of the filtrate is between 7-8; finally, put After the filter cake was rinsed with ethanol and toluene in sequence, the modified BN co-m...

Synthetic example 3

[0065] Take 120 parts of BN (D50=30um) and mix them in 3500 parts of pure water. After ball milling and dispersing for 30 minutes, add 70 parts of NaOH to it. After 12 hours of ultrasound-assisted reaction at 90°C, add hydrochloric acid to adjust the pH value at 5- 6, a uniform dispersion of activated boron nitride was obtained.

[0066] Configuration 2wt%H 2 100 parts of O / ethanol mixed solution, add 1 part of coupling agent KH550 and 2.3 parts of coupling agent KH570, and stir at 60°C for 5 minutes, adjust the pH value of the system to between 3-4, and continue stirring for 20 minutes, An activated coupling agent solution is obtained.

[0067] Pour the activated coupling agent solution into the uniform dispersion of activated boron nitride, continue to stir at 70°C for 6 hours, filter and wash the product with water several times until the pH value of the filtrate is between 7-8; finally, put After the filter cake was rinsed with ethanol and toluene in sequence, the modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com