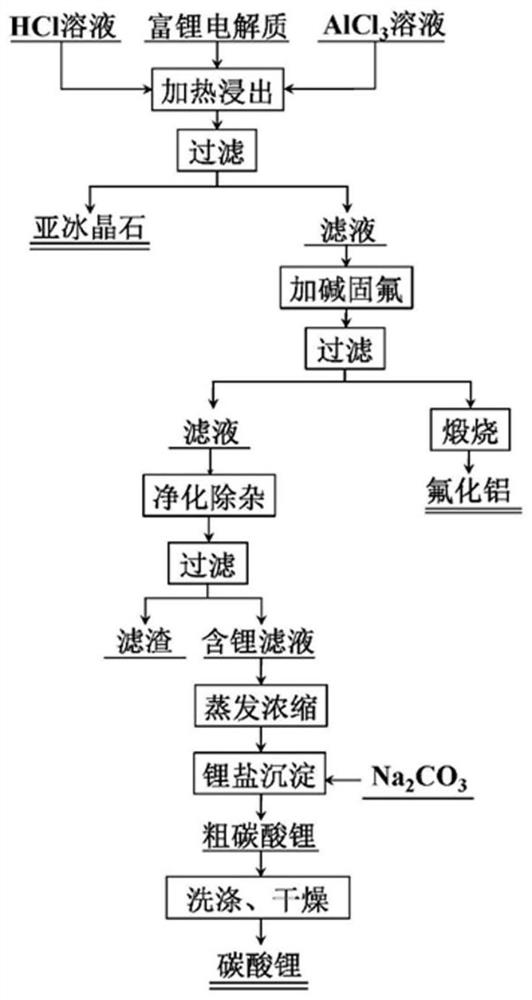

Comprehensive recovery method of waste electrolyte containing lithium and aluminum

A recovery method and electrolyte technology, applied in the direction of aluminum fluoride, aluminum halide, lithium carbonate; Low element leaching rate and other problems, to achieve efficient resource utilization, realize harmless, and solve the effect of low leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The comprehensive recovery method of waste lithium-containing aluminum electrolyte of the present invention, the detailed steps of this recovery method are as follows:

[0038] a. Sequentially crush and finely grind 100 g of the discarded lithium-containing aluminum electrolyte (the content of lithium element is 1.9%) to obtain 100-200 mesh electrolyte powder;

[0039]b. Use hydrochloric acid and water to prepare an acid solution with a concentration of 1.0 mol / L, and add 200 g of a leaching enhancer aluminum chloride hexahydrate to the prepared acid solution; then add the electrolyte powder obtained in step a into 1000 mL of the prepared acid solution , heating and stirring leaching in a constant temperature water bath under normal pressure for 2 hours, during the heating and stirring leaching process, the temperature was controlled at room temperature 25°C, and filtered after leaching to obtain filter residue A and filtrate A;

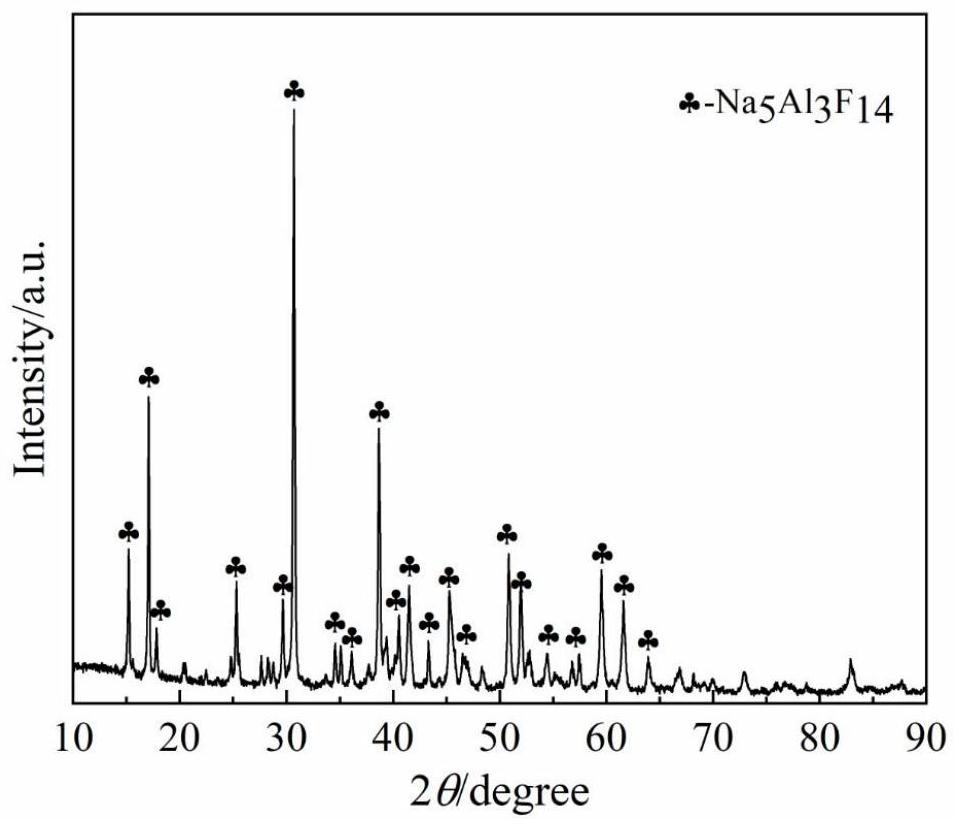

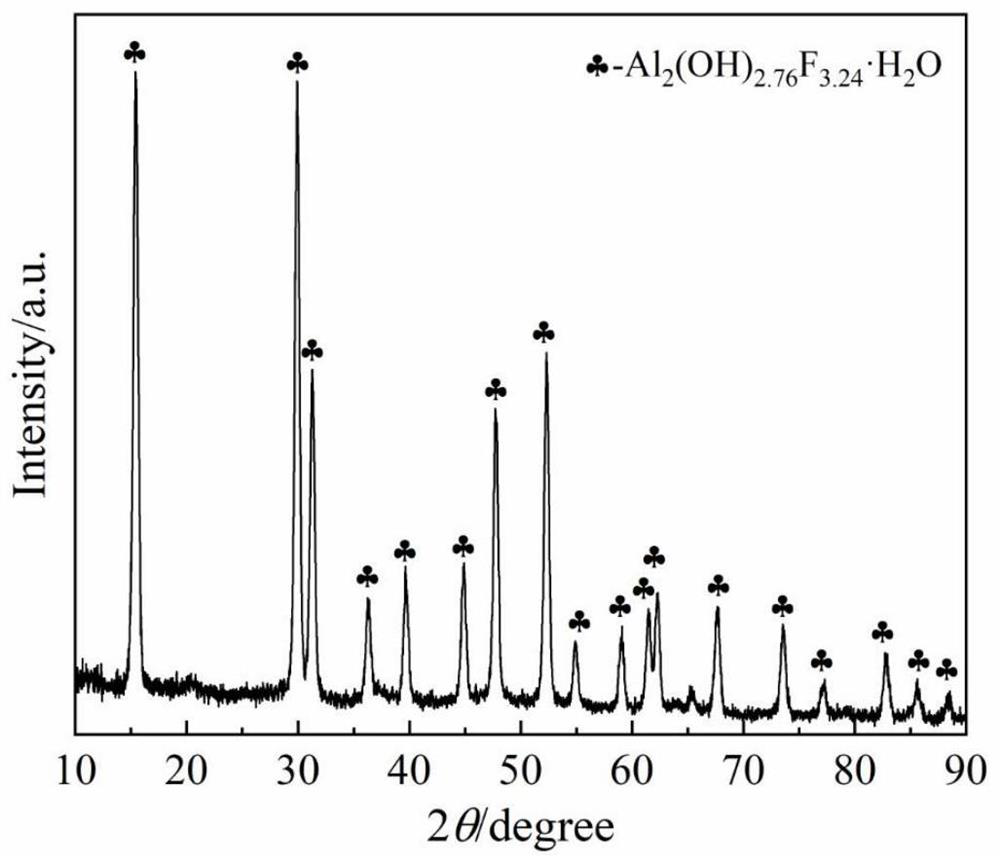

[0040] c. Wash the obtained filter resi...

Embodiment 2

[0047] The comprehensive recovery method of waste lithium-containing aluminum electrolyte of the present invention, the detailed steps of this recovery method are as follows:

[0048] a. Sequentially crush and finely grind 500 g of the waste lithium-containing aluminum electrolyte (the lithium element content is 1.5%) to obtain 200-400 mesh electrolyte powder;

[0049] b. Use hydrochloric acid to add water to prepare an acid solution with a concentration of 1.0 mol / L, and add 100 g of a leaching enhancer aluminum chloride hexahydrate to the prepared acid solution; then add the electrolyte powder obtained in step a to 700 mL of the prepared acid solution , heating and stirring leaching in a constant temperature water bath under normal pressure for 2 hours, the temperature during the heating and stirring leaching process was controlled at 80°C, and filtering was carried out after leaching to obtain filter residue A and filtrate A;

[0050] c. Wash the obtained filter residue A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com