Method for evaluating reaction performance of cellulose pulp and application thereof

A technology for the reaction performance of cellulose pulp, which is applied in the field of evaluation of the reaction performance of cellulose pulp, can solve the problems of lower product yield, poor quality and reaction performance, and influence on solvent recovery, so as to achieve both product quality and production cost , Ensure high quality and high performance, and solve the problem of raw material restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

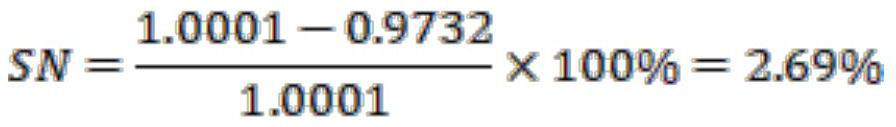

[0049] In the present embodiment, the specific steps for evaluating the reaction performance of cellulose pulp (a certain sulfite process softwood pulp) are as follows:

[0050] Pretreatment steps: Tear the wood pulp for testing into 5mm×5mm pieces, dry it to constant weight at 105°C, and balance the moisture in the desiccator for later use; configure the mass ratio of water to NMMO as 1:4 The NMMO aqueous solution was pre-equilibrated in a constant temperature water bath at 80°C.

[0051] Step (1): Submerge 1g of the above-mentioned wood pulp fragments in 10g of the above-mentioned NMMO aqueous solution, and place them in a water bath at 80°C for 10s to obtain a mixed solution of wood pulp-NMMO aqueous solution, and put a magnetic rotor into the mixed solution , adjust the rotational speed to 1000r / min, stir at 80°C for 2min, then add 10g of NMMO aqueous solution, the mass ratio of water to NMMO in the NMMO aqueous solution is 1:4, and adjust the rotational speed to 1500r / min...

Embodiment 2

[0055] In the present embodiment, the specific steps for evaluating the reaction performance of cellulose pulp (a certain sulfite process softwood pulp) are as follows:

[0056] Pretreatment steps: Tear the wood pulp used for testing into 5mm×5mm pieces, dry it to constant weight at 105°C, and balance the moisture in the desiccator for later use; configure the mass ratio of water to NMMO as 1:3 The NMMO aqueous solution was pre-equilibrated in a constant temperature water bath at 80°C.

[0057] Step (1): Submerge 1g of the above-mentioned wood pulp fragments in 25g of the above-mentioned NMMO aqueous solution, place them in a water bath at 90°C for 30s to obtain a mixed solution of wood pulp-NMMO aqueous solution, and put a magnetic rotor into the mixed solution , adjust the rotational speed to 1000r / min, stir at 90°C for 2min, then add 25g of NMMO aqueous solution, the mass ratio of water to NMMO in the NMMO aqueous solution is 1:3, and adjust the rotational speed to 1500r / mi...

Embodiment 3

[0061] In the present embodiment, the specific steps for evaluating the reaction performance of cellulose pulp (a certain sulfite process hardwood pulp) are as follows:

[0062] Pretreatment steps: Tear the wood pulp for testing into 5mm×5mm pieces, dry it to constant weight at 105°C, and balance the moisture in the desiccator for later use; configure the mass ratio of water to NMMO as 1:4 The NMMO aqueous solution was pre-equilibrated in a constant temperature water bath at 80°C.

[0063] Step (1): Submerge 1g of the above-mentioned wood pulp fragments in 10g of the above-mentioned NMMO aqueous solution, and place them in a water bath at 80°C for 10s to obtain a mixed solution of wood pulp-NMMO aqueous solution, and put a magnetic rotor into the mixed solution , adjust the rotational speed to 1000r / min, stir at 80°C for 2min, then add 10g of NMMO aqueous solution, the mass ratio of water to NMMO in the NMMO aqueous solution is 1:4, and adjust the rotational speed to 1500r / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com