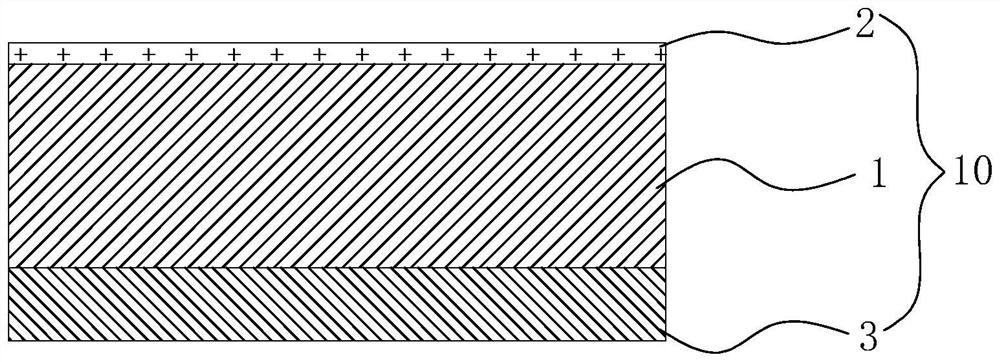

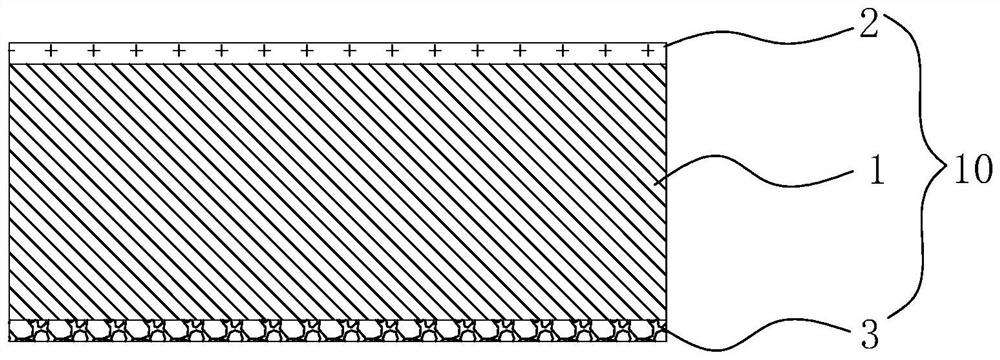

High-transmittance flexible composite front plate and preparation method thereof

A front-sheet and flexible technology, which is applied in the field of high light-transmitting flexible composite front-sheet and its preparation, can solve the problems that limit the development of flexible solar modules, and achieve the effects of facilitating promotion and application, high yield rate, and simple packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

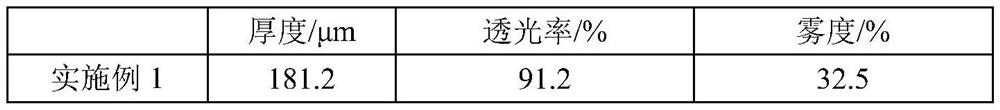

Examples

preparation example 1

[0057] The modified resin is prepared from the following raw materials in mass percentage: 15% polytrifluorochloroethylene resin, 80% tetrafluoroethylene-hexafluoropropylene resin, and 5% plastic filling master batch. The plastic filling masterbatch is AY-T80 special masterbatch, the refractive index is 1.57, and the MFR is 10g / 10min, Foshan Anyi Nano Materials Co., Ltd. The polytrifluorochloroethylene resin is Japan Daikin PCTFEM-300P, the processing grade is extrusion grade, and the characteristic grade is transparent grade. Tetrafluoroethylene-hexafluoropropylene resin is Japan Daikin NP20, MFR is 4.5-8.5g / 10min.

[0058] The preparation method of modified resin comprises the following steps:

[0059] Step 1, polytrifluorochloroethylene resin is placed at 120°C, dried for 4 hours for later use, tetrafluoroethylene-hexafluoropropylene resin is placed at 140°C, and dried for 4 hours for later use;

[0060] In step 2, place 150g of polychlorotrifluoroethylene resin, 800g of ...

preparation example 2

[0064] The difference between Preparation Example 2 and Preparation Example 1 is that the modified resin is prepared from the following raw materials in mass percentage: 10% polychlorotrifluoroethylene resin, 85% tetrafluoroethylene-hexafluoropropylene resin, 5% plastic Filler masterbatch.

preparation example 3

[0065] Preparation example 3 (comparative example)

[0066] The difference between Preparation Example 3 and Preparation Example 1 is that the modified resin is prepared from the following raw materials in mass percentage: 5% polychlorotrifluoroethylene resin, 90% tetrafluoroethylene-hexafluoropropylene resin, 5% plastic Filler masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com