Closed radial double-rotor natural gas residual pressure power generation device

A residual pressure power generation and natural gas technology, applied in the direction of electromechanical devices, oil supply devices, electric components, etc., can solve the problems of difficult installation, commissioning and construction, and complex structural components, so as to ensure stability, increase power generation efficiency, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

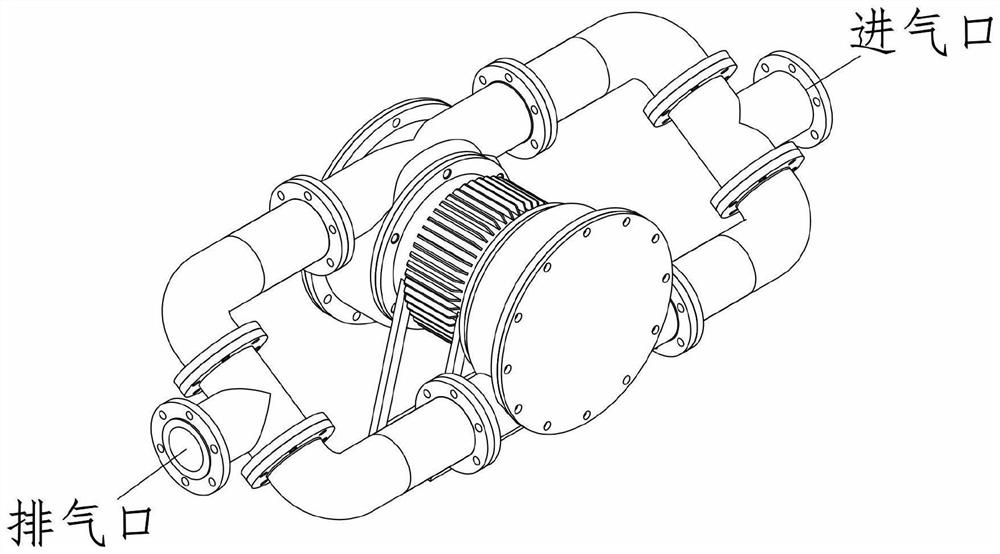

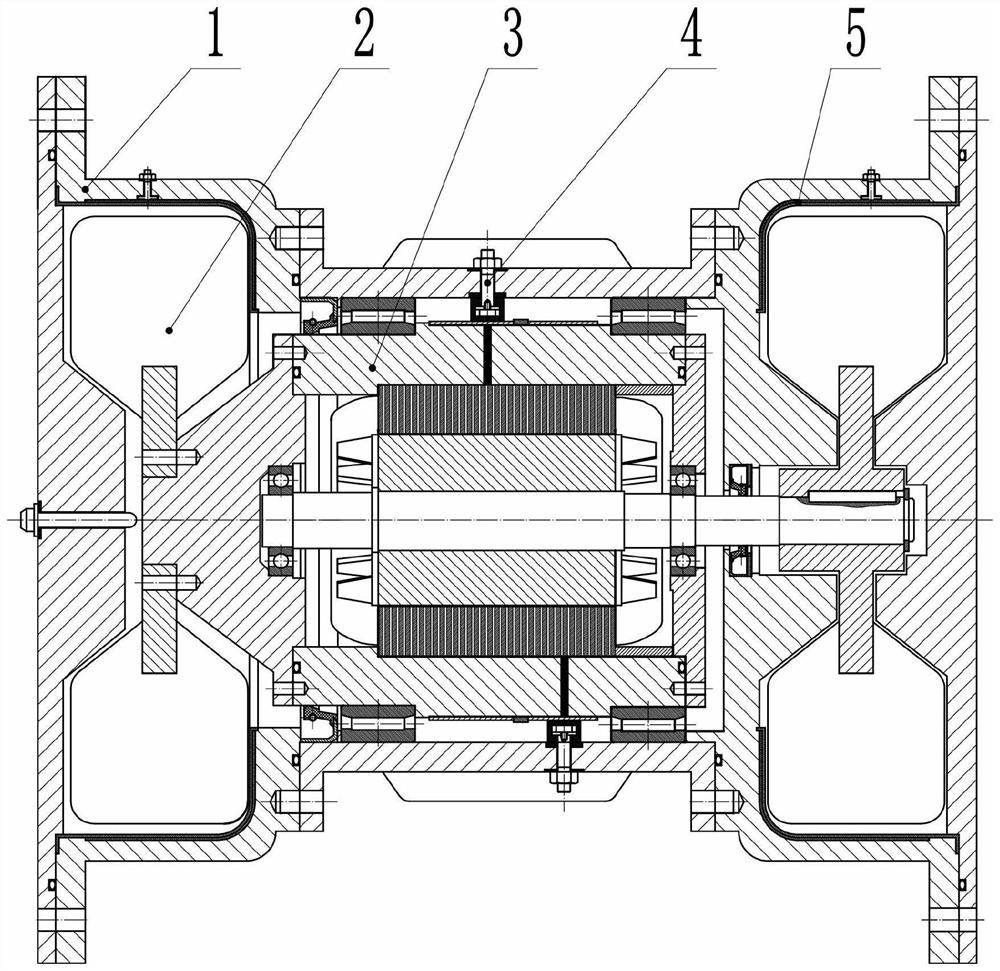

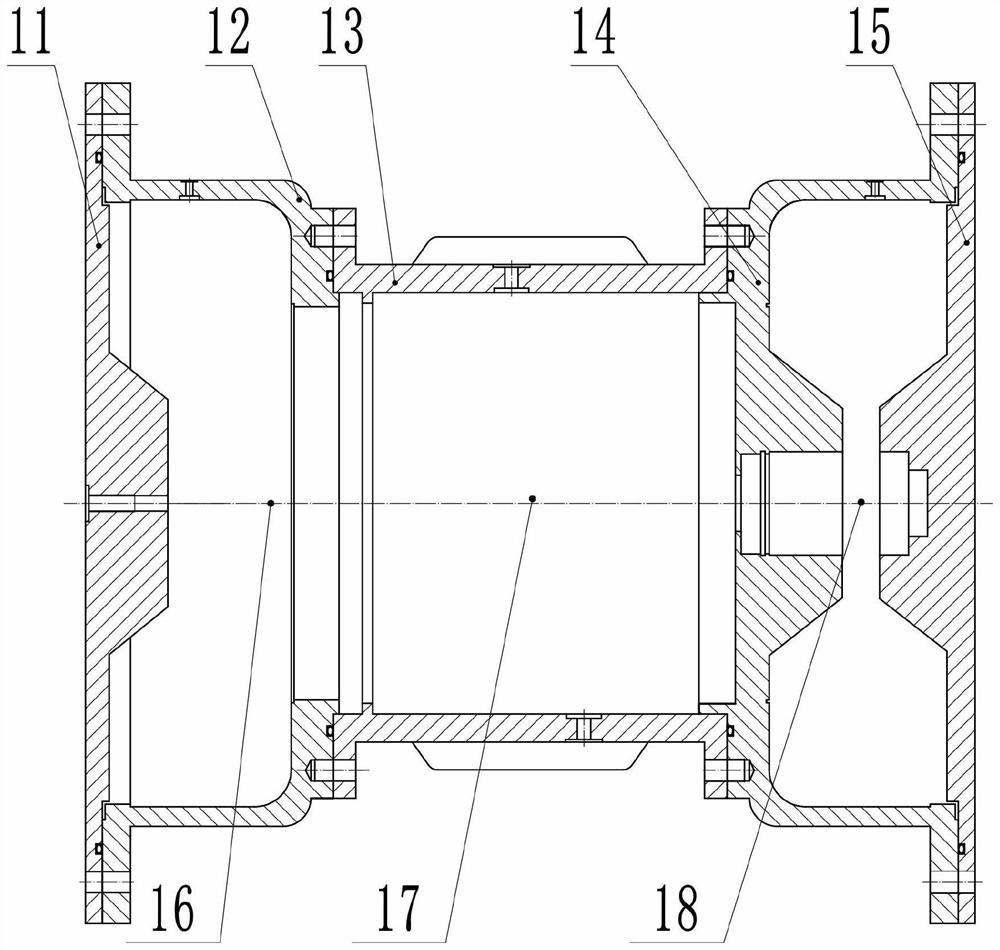

[0050] refer to Figure 1 ~ Figure 2 , a closed radial double-rotor natural gas residual pressure power generation device, consisting of a shell system 1, an energy conversion system 2, a power generation system 3, a power transmission system 4, and a heating system 5. The assembly relationship is as follows: the inside of the middle chamber 17 of the housing system 1 fixes the power generation system 3 through the outer bearing; Sliding connection; the energy conversion system 2 is fastened to the outer rotor and the inner rotor of the power generation system 3 through bolts, and installed in the left chamber 16 and the right chamber 18 respectively; the heating system 5 is installed in the left chamber by embedding. Chamber 16 and right chamber 18 inner walls. The working principle is: the high-pressure natural gas enters from the air inlet, and the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com