Simple and efficient adsorbent compounding method

An adsorbent and high-efficiency technology, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of easy loosening of adsorbents, low adsorption efficiency of adsorbents, and reduced mechanical properties, so as to improve heat transfer Mass transfer ability, improvement of material penetration performance, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

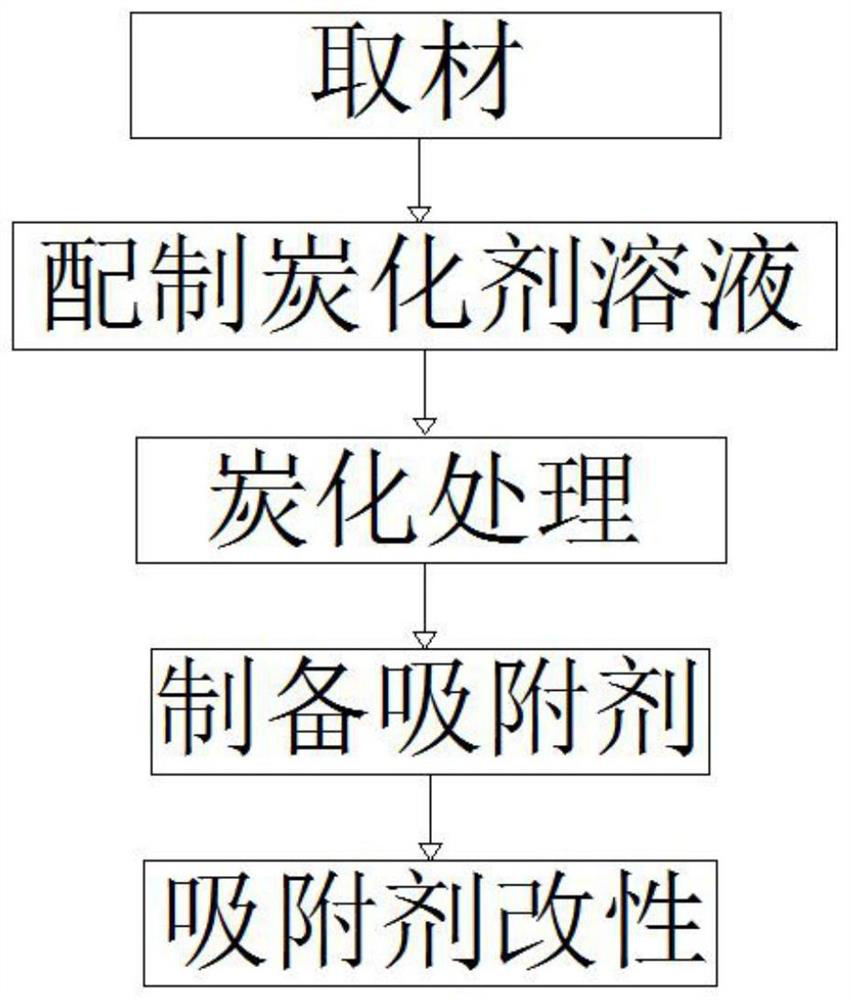

[0025] Embodiment 1, with reference to figure 1 , a simple and efficient adsorbent composite method, comprising the following steps:

[0026] S1: Materials: Use 50g-70g of diatomite, 5g-10g of activated carbon, 15g-20g of glass beads, 30g-40g of bentonite, 15g-35g of calcium chloride, 8g-16g of expanded graphite and 28g - 33 g of polyethylene oxide;

[0027] S2: Preparation of carbonizing agent solution: 10g-15g of calcium acetate, 20g-30g of citric acid and 0.5g-2g of zirconium nitrate were dissolved in 25mL of deionized water to prepare a carbonizing agent solution;

[0028] As a further improvement of the present invention, the total molar ratio of metal ions to citric acid in S2 is about 1:2, and the carbonizing agent solution in S2 needs to be stirred in a high-temperature water bath at 60°C-85°C for 1h-1.5h to ensure The solute is fully dissolved;

[0029] S3: carbonization treatment: adding the diatomite, activated carbon and bentonite prepared in S1 to the prepared ...

Embodiment 2

[0035] Embodiment 2, with reference to figure 1 , this embodiment is optimized on the basis of Example 1, specifically: a simple and efficient adsorbent composite method, which also includes the following steps:

[0036] S5: Adsorbent modification: The adsorbent particles in S4 are sequentially modified by resin, HCL, metal oxide and organic acid;

[0037] As a further improvement of the present invention, the resin modification in S5 mainly includes the synthesis of interpolymers, chloromethylation reactions, the reaction of introducing functional groups into chlorine balls, and the synthesis of adsorption resins;

[0038] More specifically: first, carry out suspension copolymerization with a certain amount of styrene, divinylbenzene and porogens of different compositions according to conventional methods, then extract the porogens, and prepare the macroporous interpolymer as Nitrobenzene is used as a swelling agent, zinc dichloride is used as a catalyst, and chloromethylati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com