Preparation method of corrosion-resistant SUS420 material

A corrosion-resistant, 2wt%-4wt% technology, used in metal processing equipment, transportation and packaging, etc., can solve problems such as poor corrosion resistance, deterioration of corrosion resistance, product failure, etc., to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

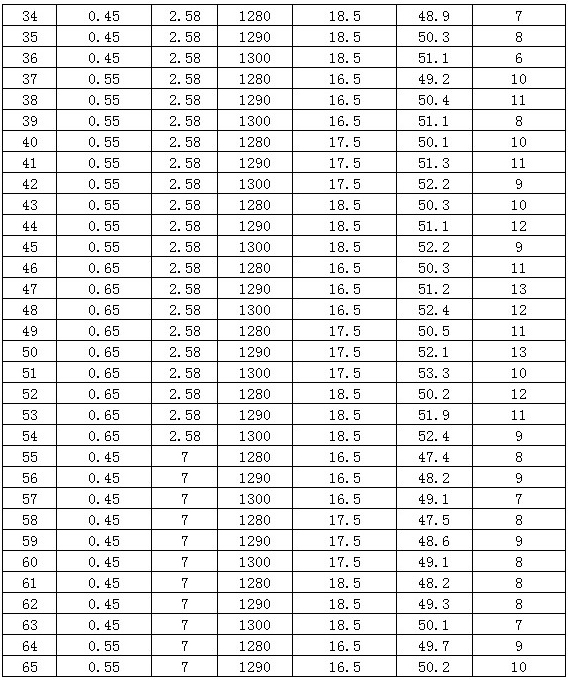

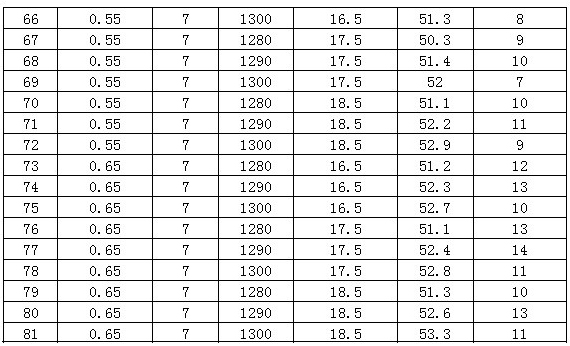

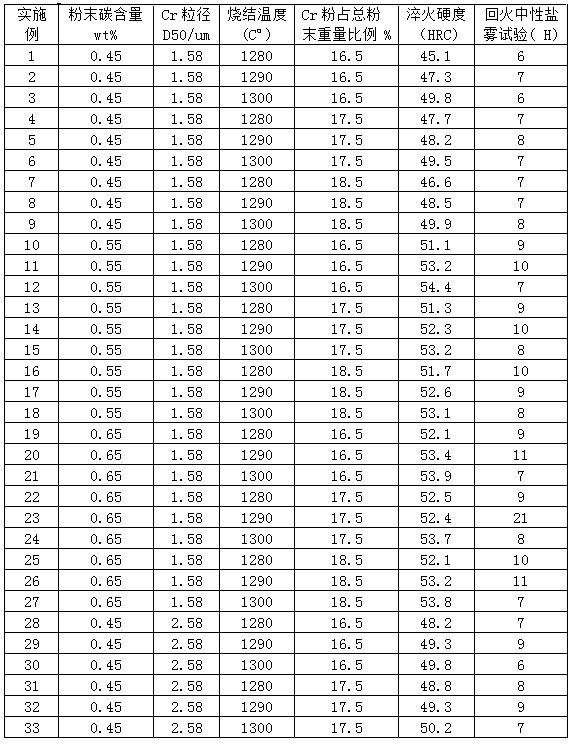

Examples

Embodiment 1

[0024] Embodiment 1: A kind of preparation method of corrosion-resistant SUS420 material, comprises the following steps: the selection of metal additive powder: MIM uses gas atomization or water atomization high-carbon alloy powder SUS420 material element composition is: carbon (C) accounts for 0.16-0.25% of the total weight of the metal powder; Manganese (Mn) ≤ 1.00% of the total weight of the metal powder; Silicon (Si) ≤ 1.00% of the total weight of the metal powder; Chromium (Cr) 12.0- 14.0%; Nickel (Ni) accounts for ≤0.75% of the total weight of the metal powder; phosphorus (P) accounts for 0.04% of the total weight of the metal powder; sulfur (S) accounts for ≤0.03% of the total weight of the metal powder; the rest of the metal powder is Fe . The elemental powder of metal chromium is selected, and the particle size D50 of the powder is 1.58 μm.

[0025] V mixing: When the carbon content of the high-carbon alloy powder SUS420 matrix metal powder used for MIM is 0.45%, add...

Embodiment 2

[0028] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated. The difference lies in: according to the preparation method in Embodiment 1, the sintering temperature is 1290°C.

Embodiment 3

[0029] Embodiment 3: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is: according to the preparation method in Embodiment 1, the sintering temperature is 1300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com