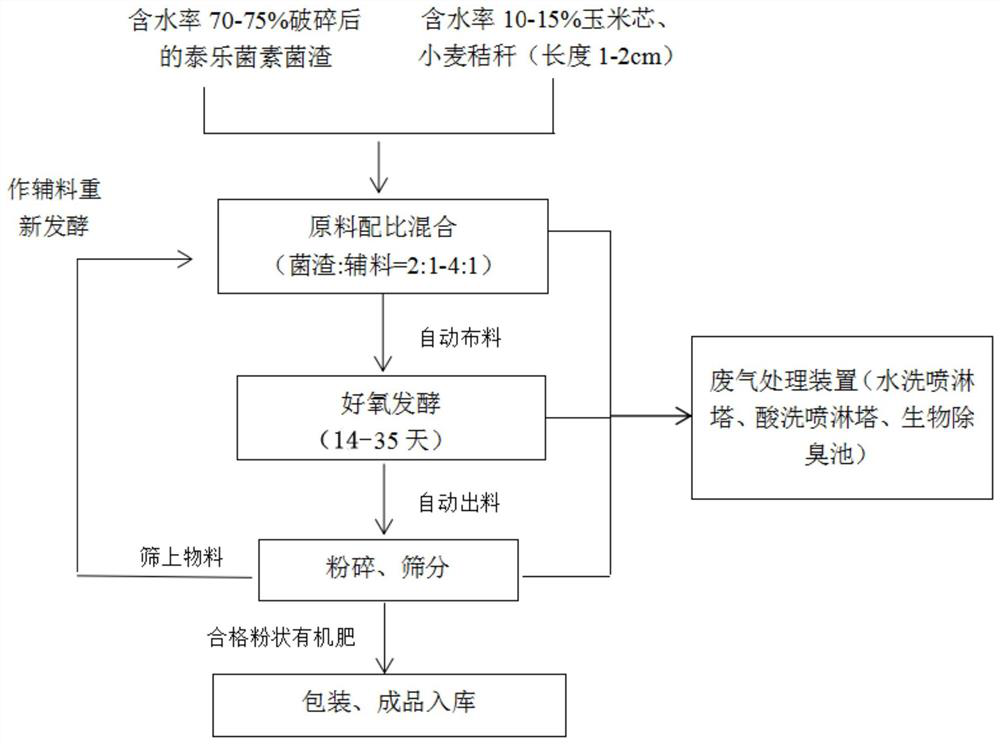

Tylosin mushroom dreg composting fermentation process

A technology of tylosin bacteria residue and fermentation process, which is applied to fertilization equipment, organic fertilizers, fertilizers made from biological waste, etc., can solve the problems of bacterial strains containing drug-resistant genes and low antibiotic removal rate, and save manpower , Improve labor productivity, and remove drug-resistant genes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

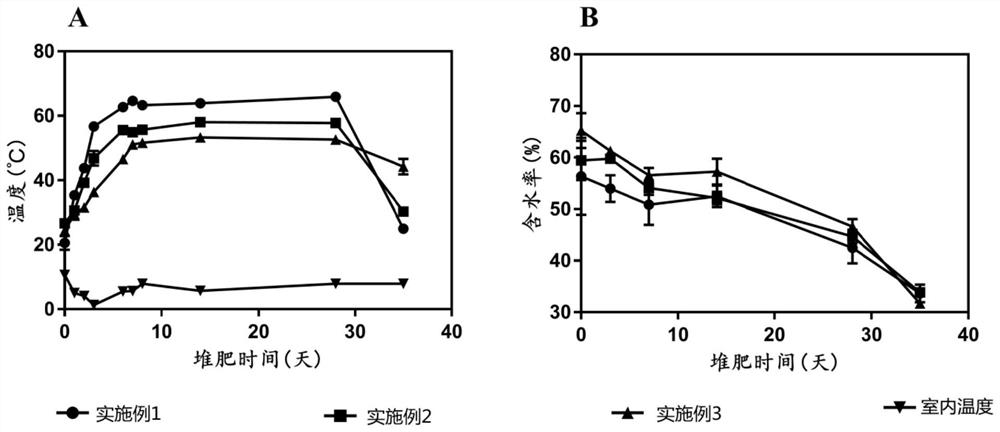

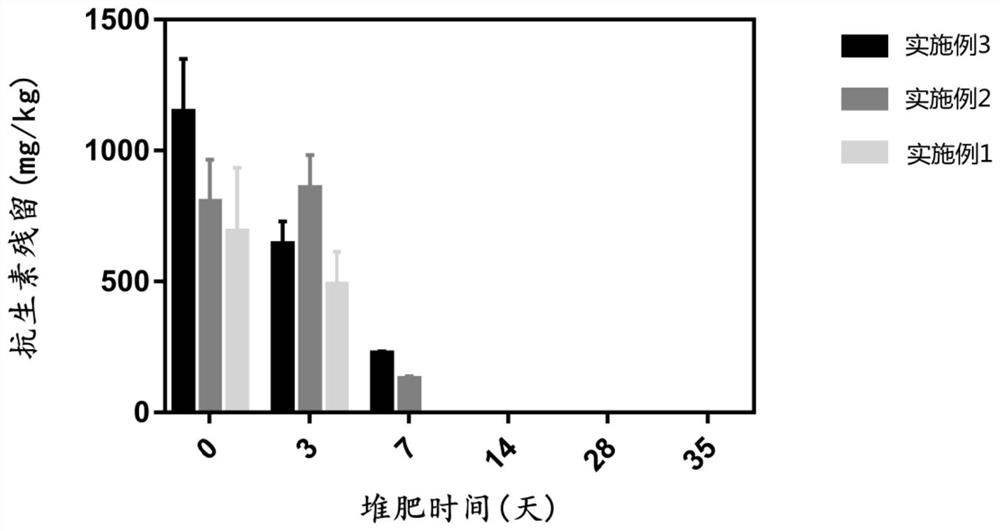

[0027] Mix the tylosin residue and wheat straw uniformly at a weight ratio of 2:1 to obtain a mixture, wherein the moisture content of the tylosin residue is 70% to 75%, and the moisture content of the wheat straw is 10% to 15%. The length of wheat straw is 1cm, and it is composted after mixing according to the above ratio. The moisture content of the mixture is kept at about 57%. The pile is not turned over for the first 3 days. ~70°C and keep it for 23 days, then lower the temperature to ferment, turn the compost once every two days, and ferment for a total of 35 days. After fermentation, the organic fertilizer is obtained by crushing and sieving, and the materials on the sieve are used as auxiliary materials for re-fermentation.

[0028] The gas generated during the mixing process of tylosin bacteria residue and auxiliary materials, the aerobic fermentation process and the pulverization and screening process is collected and passed to the waste gas treatment device for trea...

Embodiment 2

[0030] Mix the tylosin residue and corncob evenly in a weight ratio of 2:1 to obtain a mixture, wherein the moisture content of the tylosin residue is 70% to 75%, and the moisture content of the corncob is 10% to 15%. The length of the corn cob is 2cm, and it is composted after mixing according to the above ratio. The moisture content of the mixture is kept at about 60%, and the compost is not turned over for the first 3 days. ~70°C and keep the temperature down for 22 days to ferment, turn the compost once every two days, and ferment for a total of 35 days. After fermentation, the organic fertilizer is obtained by crushing and sieving, and the materials on the sieve are used as auxiliary materials for re-fermentation.

[0031] The gas generated during the mixing process of tylosin bacteria residue and auxiliary materials, the aerobic fermentation process and the pulverization and screening process is collected and passed to the waste gas treatment device for treatment, and th...

Embodiment 3

[0033] Mix the tylosin residue and corncob evenly in a weight ratio of 4:1 to obtain a mixture, wherein the moisture content of the tylosin residue is 70% to 75%, and the moisture content of the corncob is 10% to 15%. The length of the corn cob is 2cm, and it is composted after mixing according to the above ratio. The moisture content of the mixture is kept at about 65%. The compost is not turned over for the first 3 days. After the temperature rises to 55-60°C, the compost is turned over for fermentation. ~70°C and keep the temperature down for 21 days to ferment, turn the compost once every two days, and ferment for a total of 35 days. After fermentation, the organic fertilizer is obtained by crushing and sieving, and the materials on the sieve are used as auxiliary materials for re-fermentation.

[0034] The gas generated during the mixing process of tylosin slag and auxiliary materials, the aerobic fermentation process and the crushing and screening process is collected an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com