Simulated Mars soil formula and preparation method thereof

A mars and soil technology, applied in the fields of agriculture, scientific research, and aerospace, can solve the problems of difficult to obtain ingredients, complex preparation methods, and many types of raw materials, and achieve the effects of not easy composition deviation, simple preparation equipment, and single composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

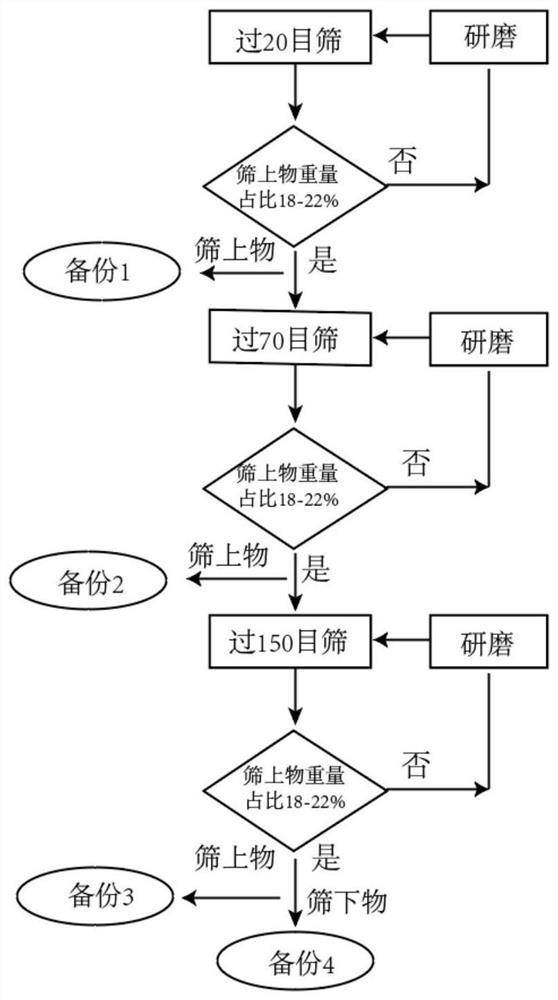

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares 100 kilograms of simulated Martian soil

[0027] Prepare 20 kg of ultramafic volcanic lava, or 20 kg of mafic volcanic lava. Among them, those with a particle diameter of more than one millimeter account for no less than 20% of the total weight. 20 kg of albite raw ore is selected, of which the particle size of more than one millimeter accounts for no less than 20% of the total weight. Select 15 kg each of diopside raw ore, forsterite raw ore and quartz stone. Among them, those with a particle size of more than one millimeter account for no less than 15% of the total weight. Choose 10 kg of calcite raw ore. Among them, those with a particle size of more than one millimeter account for no less than 20% of the total weight. Prepare 2 kg each of hematite, magnetite and anhydrite. Among them, those with a particle size of more than one millimeter account for no less than 20% of the total weight. Prepare 4 kg of industrial grade anhydrous magnesiu...

Embodiment 2

[0036] Prepare the simulated Martian soil according to the method described in Example 1, the types of raw materials are the same, but the weight parts are different, and the weight parts proportioning is as follows:

[0037] Volcanic lava 15 parts, albite 15 parts, diopside 12 parts, forsterite 12 parts, quartzite 12 parts, calcite 5 parts, anhydrous magnesium sulfate 3 parts, hematite 1 part, magnetite 1 part , 1 part of anhydrite.

Embodiment 3

[0039] Prepare the simulated Martian soil according to the method described in Example 1, the types of raw materials are different, but the parts by weight are different, and the proportioning of parts by weight is as follows:

[0040]Volcanic lava 25 parts, albite 25 parts, diopside 18 parts, forsterite 18 parts, quartzite 18 parts, calcite 10 parts, anhydrous magnesium sulfate 6 parts, hematite 4 parts, magnetite 4 parts , 2 parts of anhydrite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com