Carbon hollow sphere coated metal selenide composite material as well as preparation method and application thereof

A technology of metal selenide and composite materials, which is applied in the field of carbon hollow sphere-coated metal selenide composite materials and its preparation, can solve the problems of unfavorable kinetics and poor cycle stability, and achieve high cycle stability and excellent energy storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

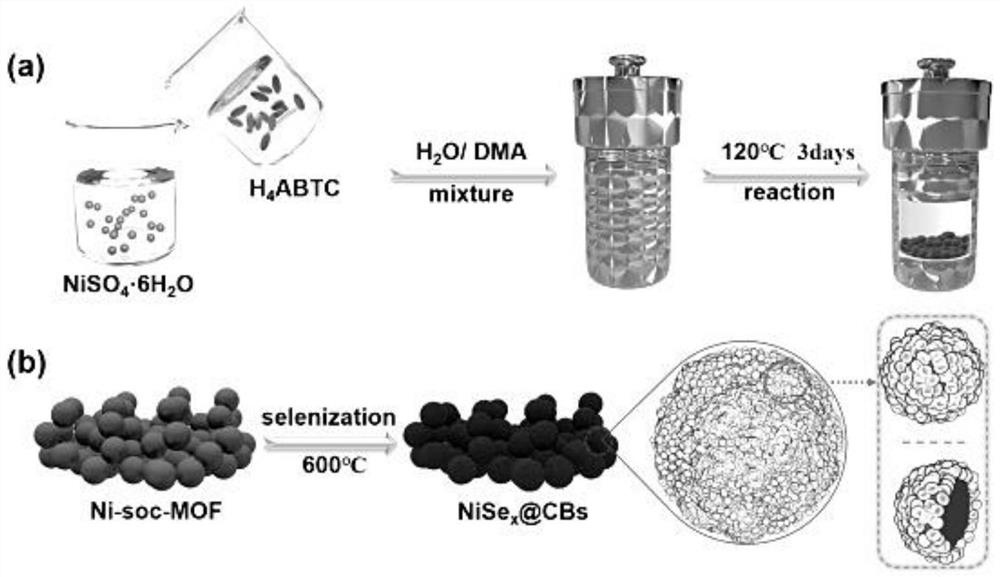

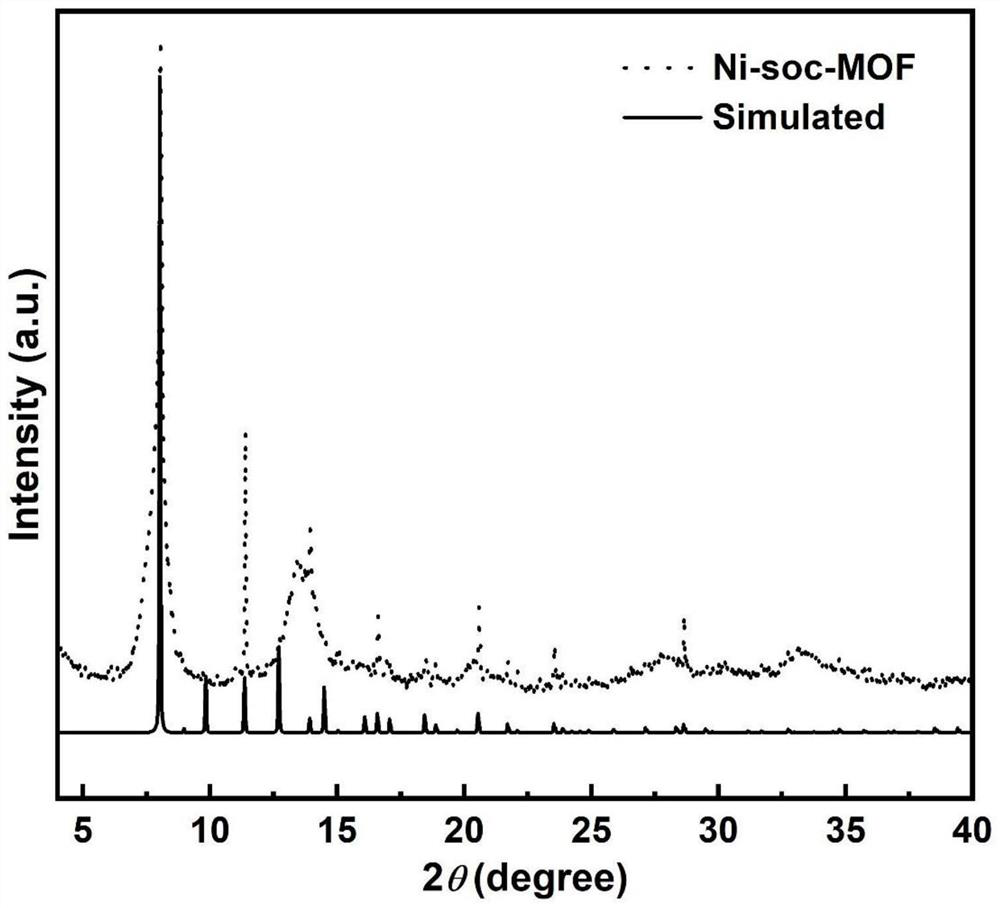

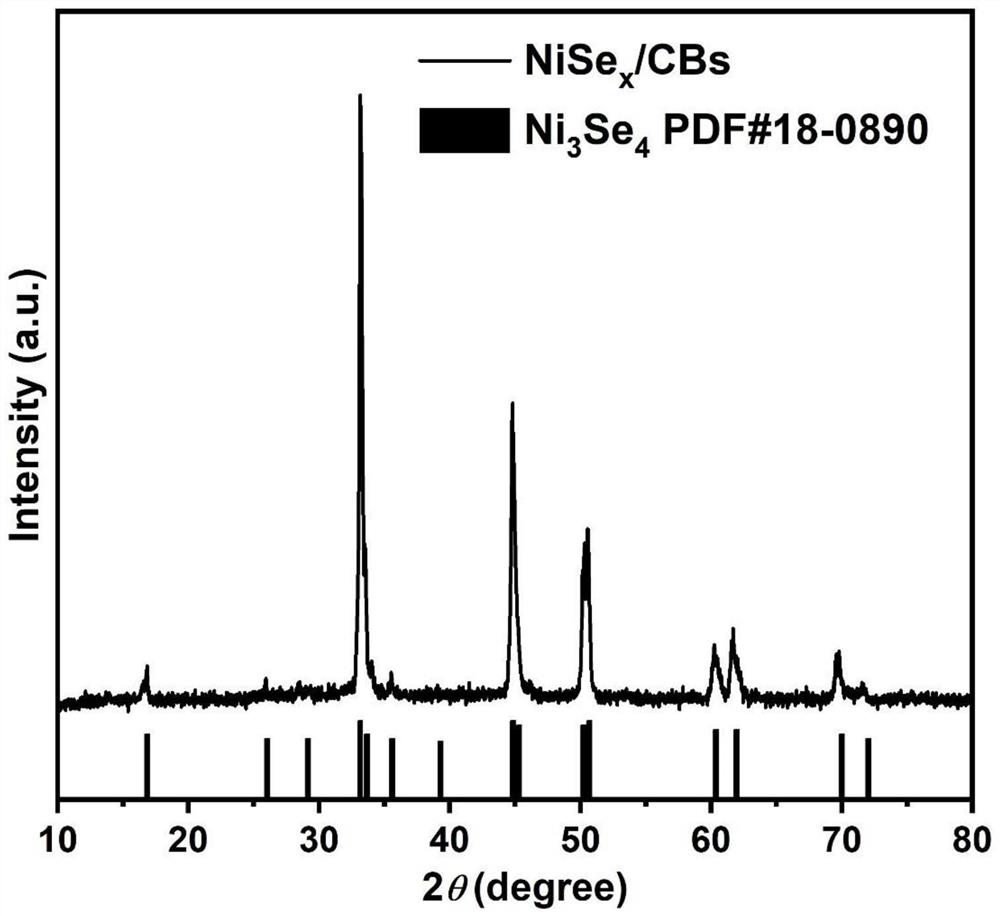

[0037] Example 1 A carbon hollow sphere coated metal selenide composite material and its preparation method

[0038] see Figure 1-13 , the invention is a carbon hollow sphere coated metal selenide composite material, the composite material is a double-layer structure, and the inner layer of the composite material is NiSe x Nanoparticles, the outer layer of the composite material is carbon hollow spheres, and the inner layer of the composite material is NiSe x Nanoparticles are evenly dispersed inside the carbon hollow spheres;

[0039] The preparation method of the carbon hollow sphere coated metal selenide composite material mainly includes the following steps:

[0040] Step 1: Ni(SO 4 ) 2 ·6H 2 O and H 4 ABTC was dissolved in 3ml N,N-dimethylacetamide, 1ml H 2 In the mixture of O and 1ml tetrafluoroboric acid, mixed solution A is obtained after stirring;

[0041] Step 2: Put the mixed solution A in a stainless steel reactor, and then place the stainless steel reacto...

Embodiment 2

[0043] Example 2 A carbon hollow sphere coated metal selenide composite material and its preparation method

[0044] The invention is a carbon hollow sphere coated metal selenide composite material, the composite material has a double-layer structure, and the inner layer of the composite material is NiSe x Nanoparticles, the outer layer of the composite material is carbon hollow spheres, and the inner layer of the composite material is NiSe x Nanoparticles are evenly dispersed inside the carbon hollow spheres;

[0045] The preparation method of the carbon hollow sphere coated metal selenide composite material mainly includes the following steps:

[0046] Step 1: Ni(SO 4 ) 2 ·6H 2 O and H 4 ABTC was dissolved in 6ml N,N-dimethylacetamide, 1ml H 2 In the mixture of O and 1ml tetrafluoroboric acid, mixed solution A is obtained after stirring;

[0047] Step 2: Put the mixed solution A in a stainless steel reactor, and then place the stainless steel reactor in an oven at 120...

Embodiment 3

[0049] Example 3 A carbon hollow sphere coated metal selenide composite material and its preparation method

[0050] The invention is a carbon hollow sphere coated metal selenide composite material, the composite material has a double-layer structure, and the inner layer of the composite material is NiSe x Nanoparticles, the outer layer of the composite material is carbon hollow spheres, and the inner layer of the composite material is NiSe x Nanoparticles are evenly dispersed inside the carbon hollow spheres;

[0051] The preparation method of the carbon hollow sphere coated metal selenide composite material mainly includes the following steps:

[0052] Step 1: Ni(SO 4 ) 2 ·6H 2 O and H 4 ABTC was dissolved in 6ml N,N-dimethylacetamide, 2ml H 2 In the mixture of O and 1ml tetrafluoroboric acid, mixed solution A is obtained after stirring;

[0053] Step 2: Put the mixed solution A in a stainless steel reactor, and then place the stainless steel reactor in an oven at 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com