Preparation method of low-GI tea polyphenol-starch compound with bacteriostatic effect

A technology of antibacterial effect and tea polyphenols is applied in the field of preparation of low GI tea polyphenols-starch complexes, and can solve the problems of reducing the edible quality of products, poor taste, and unripe products, and achieves low production cost, simple operation, and low cost. Highly feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of the low GI tea polyphenol-starch compound with bacteriostasis, the steps are as follows:

[0034] 1) Weigh 100g high amylose cornstarch, add 0.05M sodium phosphate buffer solution with pH 7.5 until the volume of starch milk is 1000mL;

[0035] 2) After the starch milk was preheated in a water bath shaker at 50°C for 15 minutes, 3 mL of branching enzyme was added to it, and continued to be enzymolyzed in a water bath shaker at 50°C for 10 hours, then the enzyme activity was inactivated in a boiling water bath for 10 minutes, and cooled to room temperature to obtain the enzyme Solution;

[0036] 3) Add tea polyphenols with 6% substrate mass to the enzymolysis solution, react in a water-bath shaker at 30° C. for 2 hours; then centrifuge at 4000 r / min for 10 minutes to obtain a precipitate.

[0037] 4) Add 3 times the volume of 50% (volume concentration, the same below) ethanol to the precipitate, and centrifuge at 4000r / min for 10 minutes t...

Embodiment 2

[0042] 1) Weigh 100g high amylose cornstarch, add 0.05M sodium phosphate buffer solution with pH 7.5 until the volume of starch milk is 1000mL;

[0043]2) Starch milk was preheated in a water-bath shaker at 50°C for 15 minutes, then 2 mL of branching enzyme was added to it, and continued to be enzymolyzed in a water-bath shaker at 50°C for 10 hours, then in a boiling water bath for 10 minutes to inactivate the enzyme activity, and cooled to room temperature to obtain enzymatic solution;

[0044] 3) Add tea polyphenols with a substrate mass of 6% to the enzymolysis solution, react in a water-bath shaker at 30°C for 2 hours; then centrifuge at 4000r / min for 10min to obtain a precipitate;

[0045] 4) Same as step 4) of Example 1 to obtain the tea polyphenol-starch complex.

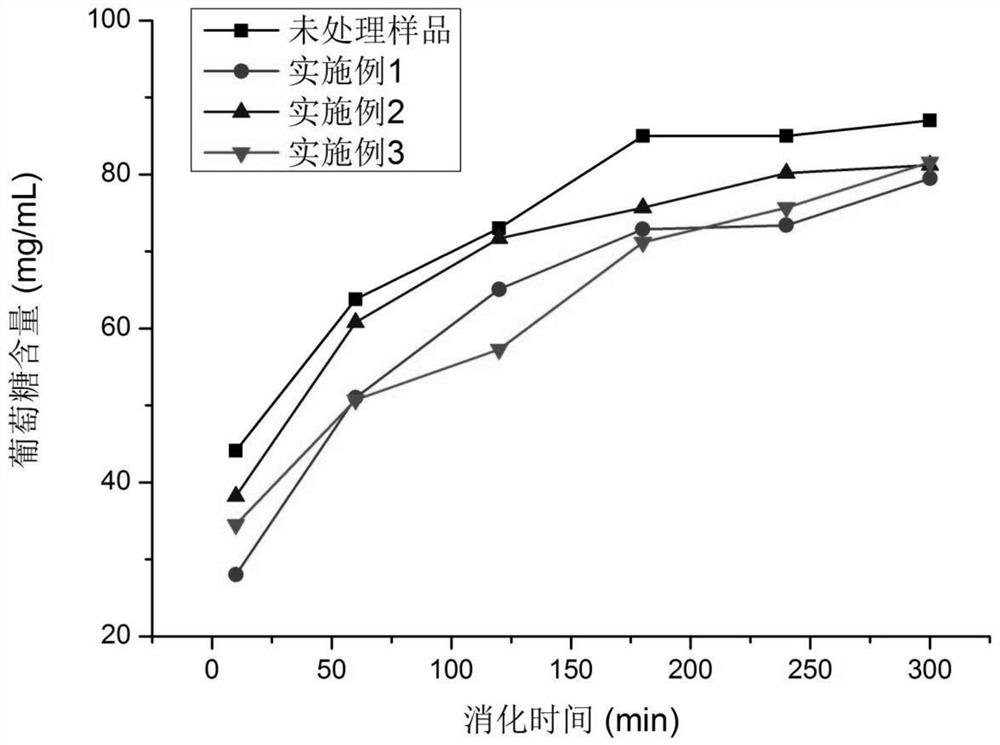

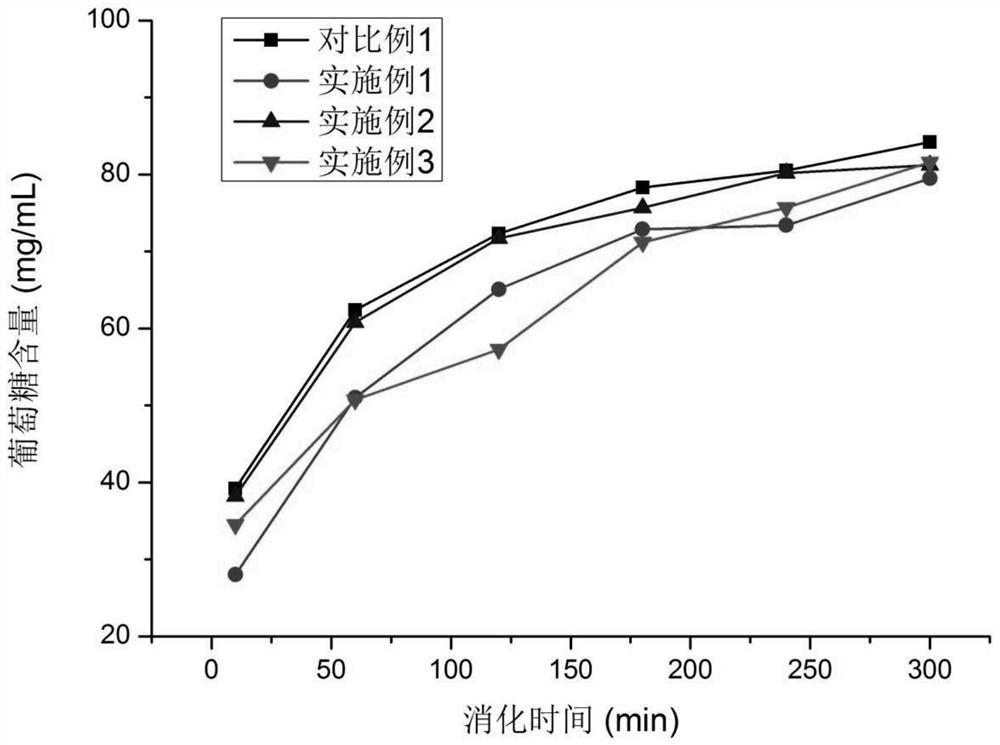

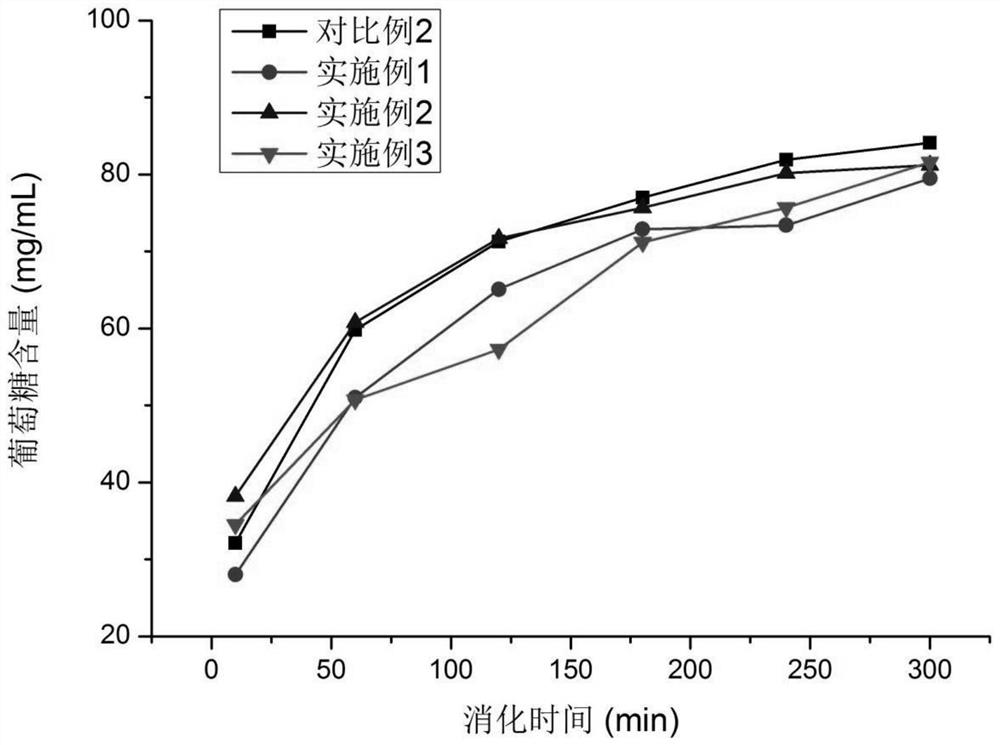

[0046] The compound obtained in this example was subjected to an in vitro digestion simulation experiment, and the glucose content changes in the in vitro digestion process were as follows: figure 1 As show...

Embodiment 3

[0050] 1) Weigh 100g high amylose cornstarch, add 0.05M sodium phosphate buffer solution with a pH of 7.5 until the starch milk volume is 1000mL;

[0051] 2) Starch milk was preheated in a water-bath shaker at 50°C for 15 minutes, then 3 mL of branching enzyme was added to it, and continued to be enzymatically hydrolyzed in a water-bath shaker at 50°C for 10 hours, then in a boiling water bath for 10 minutes to inactivate the enzyme activity, and cooled to room temperature to obtain enzymatic solution;

[0052] 3) Add tea polyphenols with 4% substrate mass to the enzymolysis solution, react in a water-bath shaker at 30° C. for 2 hours; then centrifuge at 4000 r / min for 10 minutes to obtain a precipitate.

[0053] 4) Same as step 4) of Example 1 to obtain the tea polyphenol-starch complex.

[0054] The compound obtained in this example was subjected to an in vitro digestion simulation experiment, and the glucose content changes in the in vitro digestion process were as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com