Slow-digestion type whole-grain energy bar and preparation method thereof

A technology of whole grains and energy bars, applied in the field of energy bars, can solve problems such as unsustainable energy supply, and achieve the effects of improving action efficiency, alleviating rough taste, and enriching nutrition and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Follow these steps to make a slow-digesting whole grain energy bar:

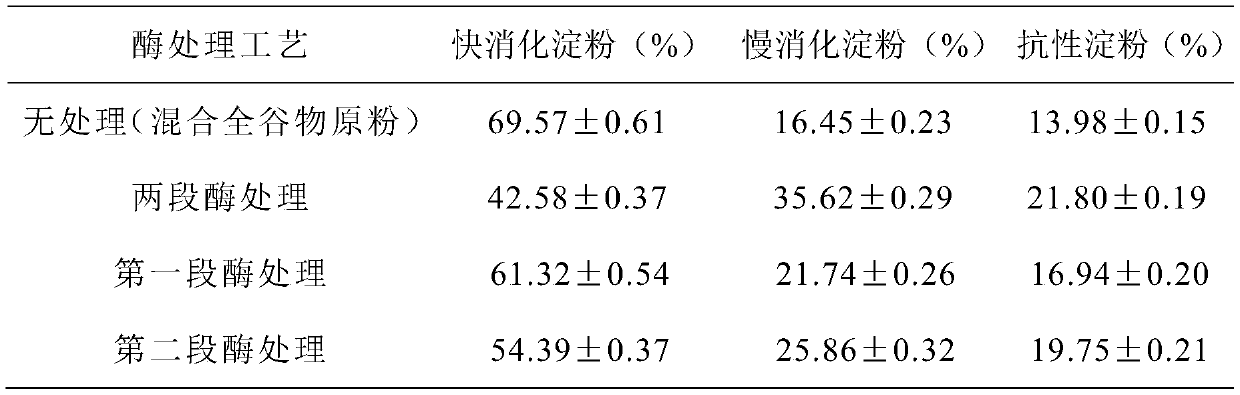

[0041] 1. Preparation of highly branched mixed whole grain flour

[0042] (1) Weigh brown rice, corn, buckwheat, oats, and millet of equal quality and mix them evenly to obtain mixed whole grains, and add purified water 4.5 times its total mass (obtained from tap water through purified water equipment, and the treatment process of purified water equipment is recommended) But not limited to: tap water → booster pump → multi-media filter → activated carbon filter → security filter → high pressure pump → first-stage reverse osmosis → purified water, or directly use commercially available purified water,) and put it into the beater In beating, the obtained uniform slurry is passed through a colloid mill to further obtain a mixed whole grain slurry with a smaller particle size and a finer grain size;

[0043](2) Place the mixed whole grain slurry in a water bath shaker at 45°C for 25 minutes, and then add...

Embodiment 2

[0068] Prepare Slow Digesting Whole Grain Energy Bars as follows:

[0069] 1. Preparation of highly branched mixed whole grain flour

[0070] (1) Take black rice, corn, buckwheat, oats, millet of equal quality and mix evenly, add the purified water of 4.2 times of its total mass, put into the beating machine and beat, and the uniform slurry obtained will be passed through colloid mill to further obtain finer grain size Smaller, finer blended whole grain slurries;

[0071] (2) Put the mixed whole grain slurry in a water bath shaker at 42°C for 28 minutes, then add food-grade cellulase and starch branching enzyme according to the dosage of 11U / g and 24U / g mixed whole grain respectively and stir evenly, keeping at React in a water bath shaker at 42°C for 11 hours to complete the first stage of enzyme treatment;

[0072] (3) Remove the first stage of enzyme-treated mixed whole grain slurry, place it in a boiling water bath for 38 minutes, complete the gelatinization treatment of...

Embodiment 3

[0081] Prepare Slow Digesting Whole Grain Energy Bars as follows:

[0082] 1. Preparation of highly branched mixed whole grain flour

[0083] (1) Weigh brown rice, corn, buckwheat, oats, and millet of the same quality and mix them evenly, add purified water 5 times the total mass, put them into a beater for beating, and pass the obtained uniform slurry through a colloid mill to further obtain a smaller particle size A finer blend of whole grain slurries;

[0084] (2) Put the mixed whole grain slurry in a water bath shaker at 50°C for 20 minutes, then add food-grade cellulase and starch branching enzyme according to the dosage of 15U / g and 21U / g mixed whole grain respectively and stir evenly, keeping at React in a water bath shaker at 48°C for 9 hours to complete the first stage of enzyme treatment;

[0085] (3) Remove the mixed whole grain slurry from the first stage of enzyme treatment, place it in a boiling water bath for 40 minutes, complete the gelatinization treatment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com