Auxiliary pressure-stabilizing feeding system for pressure-stabilizing tank of filter press and step-by-step pressure-stabilizing feeding method

A feeding system and pressure-stabilizing tank technology, which is applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems affecting the filtration effect and production efficiency, uniform mixed fluid resistance, uneven feeding of filter chambers, etc. problems, to achieve the effect of consistent filter cake wetness, consistent product quality and balanced pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

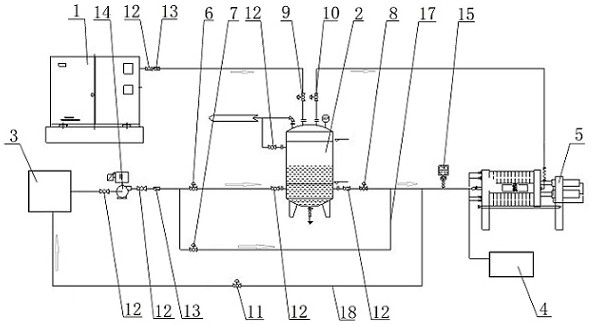

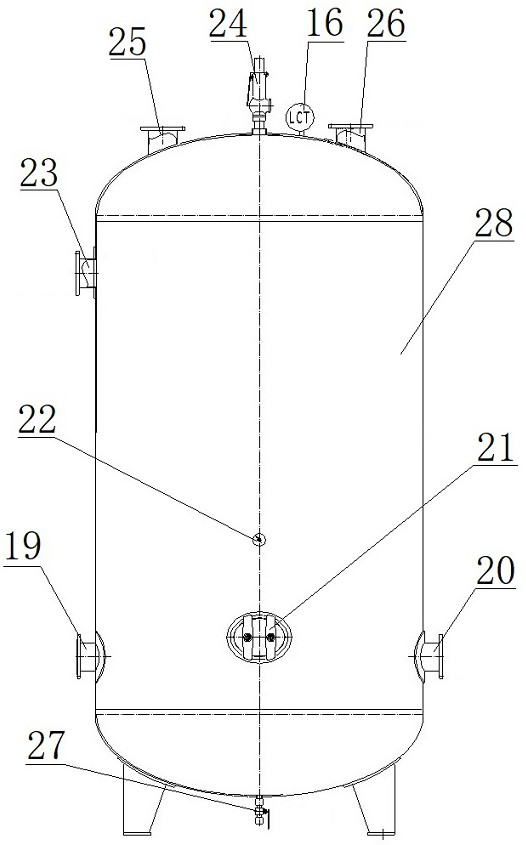

[0017]A pressure-stabilizing tank-assisted steady-pressure feeding system for a filter press (hereinafter referred to as: step-by-step steady-pressure feeding system), that is, a step-by-step steady-pressure feeding and backflushing and plugging-clearing system; key points of an innovative overall implementation plan Yes: Improve the existing one-step unstabilized pressure feeding and back-blowing and blocking-clearing system of the series-connected filter chambers, and improve the component-step steady-pressure feeding and back-blowing and blocking-clearing system, including air compressor 1, material pump 2, and surge tank 3 , material pool 5, pressure sensor 19, material conveying main road 21, material conveying bypass 22, air pressure pipeline 23, return pipeline 24, various pipeline valves; material pool 5, material pump 2, surge tank 3 And the filter press 4 are arranged in sequence from left to right; the main feeding road 21 is connected in series with the material poo...

Embodiment 2

[0028] An automatic filter press unit, which uses the pressure-stabilizing tank-assisted steady-pressure feeding system (abbreviation: step-by-step steady-pressure feeding system) of the filter press provided by the present invention; the automatic filter press unit is mainly composed of an automatic filter press 4. Composed of step-by-step stable pressure feeding system, hydraulic station, filtrate pool 6, filter cake storage and transportation equipment; automatic filter press 4, including double beam frame, filter plate pressing mechanism, multi-filter chamber filter mechanism, flap Liquid contact mechanism, plate pulling and cake unloading mechanism, filter cloth cleaning mechanism, PLC program control system; step-by-step stable pressure feeding system, that is, step-by-step stable pressure feeding and back-blowing and blocking-clearing system, including air compressor 1 (abbreviation: air compressor 1) press), material delivery pump 2 (abbreviation: material pump), materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com