High-pressure-resistant precision aluminum alloy circular tube

An aluminum alloy, high pressure-resistant technology, which is applied in metal processing, tubular objects, metal processing equipment, etc., can solve the problems of aluminum alloy round tubes such as sag, low compression coefficient, and weak support, so as to improve the compression coefficient , Improve the reinforcement effect and reduce the overall weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

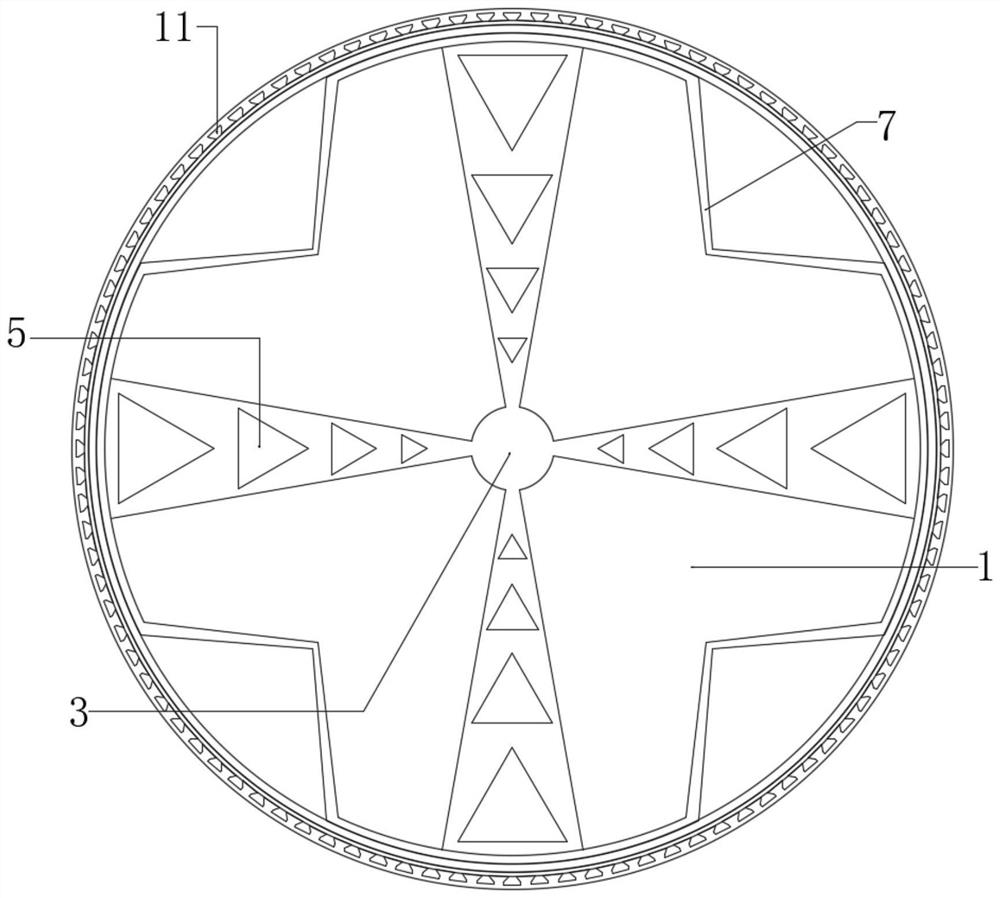

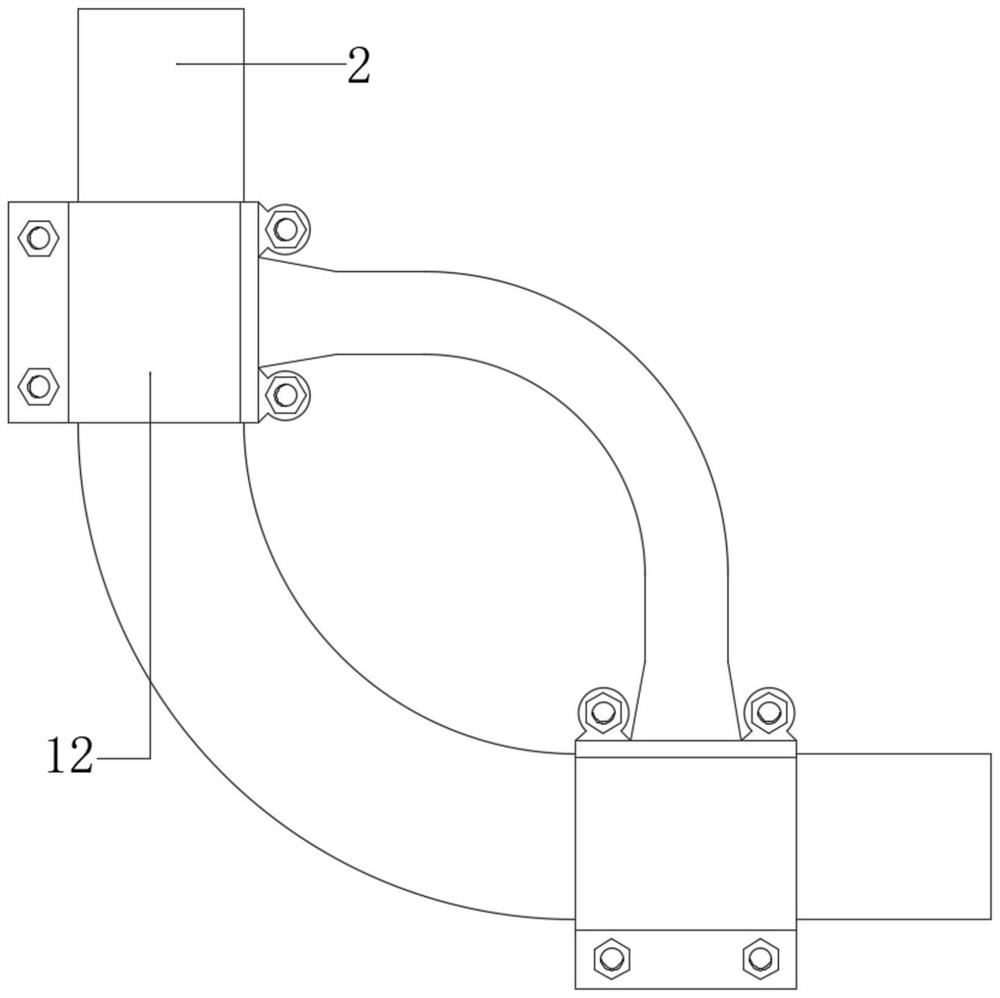

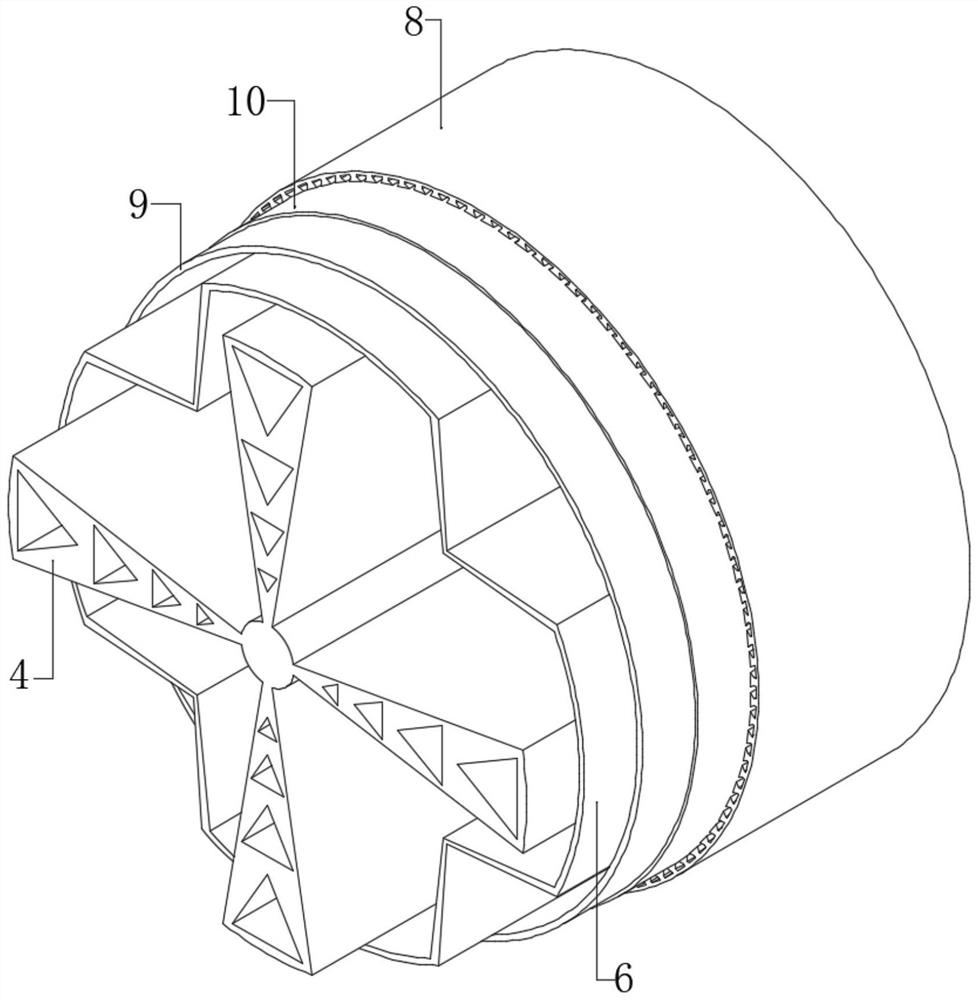

[0027] A high-pressure precision aluminum alloy round tube, such as figure 1 , figure 2 and image 3 As shown, it includes a straight pipe 1 and an elbow 2. A central shaft 3 is arranged inside the straight pipe 1, and the outer wall of the central shaft 3 is provided with four built-in dispersed support members 4, and the four built-in dispersed support members 4 are all Distributed equidistantly around the circumference, multiple triangular stabilizing holes 5 are provided on the four internally attached dispersed support members 4, and the size of the multiple triangular stabilizing holes 5 increases gradually from the inside to the outside, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com