Satellite vibration isolation/reduction support made of chopped carbon fiber reinforced thermoplastic composite material

A technology for reinforcing thermoplastic and chopped carbon fibers, which is applied in non-rotational vibration suppression, space navigation equipment, space navigation aircraft, etc. Easy to scale production, low cost, strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example 1

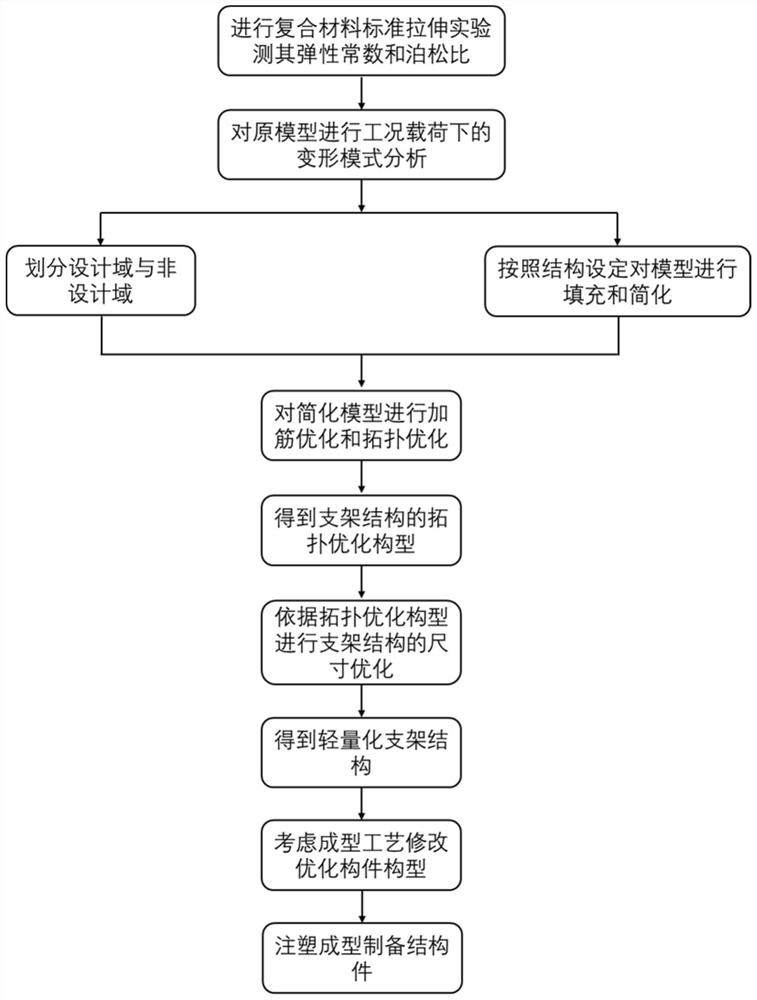

[0032] The specific example 1 is the design of the satellite isolation / vibration damping bracket of the chopped carbon fiber reinforced PPS composite material, and the steps are as follows:

[0033] 1) Perform a standard tensile test to test the basic mechanical properties of the composite material to obtain the elastic constant and Poisson's ratio. The tensile elastic modulus of the composite material is 28GPa, and the Poisson's ratio is 0.35.

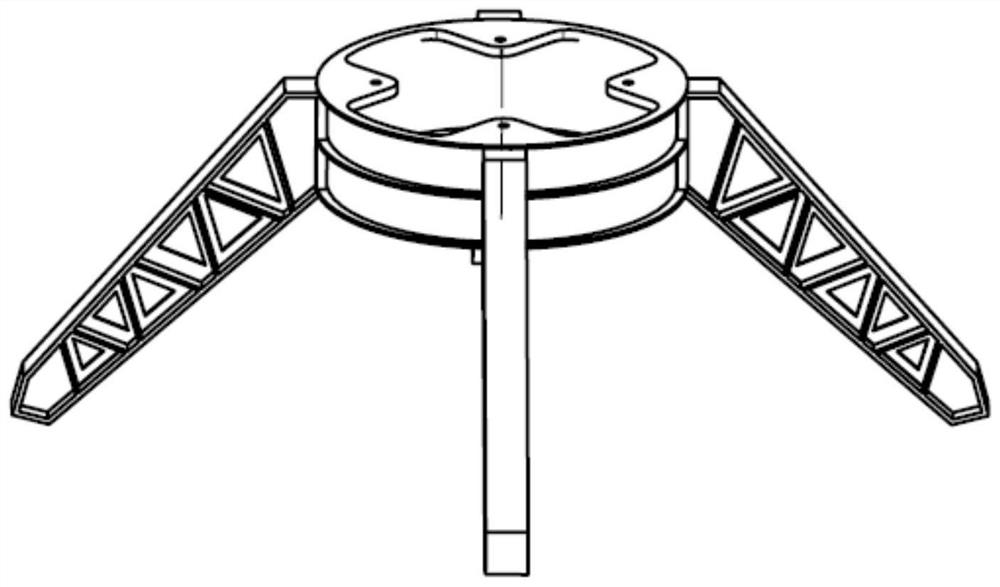

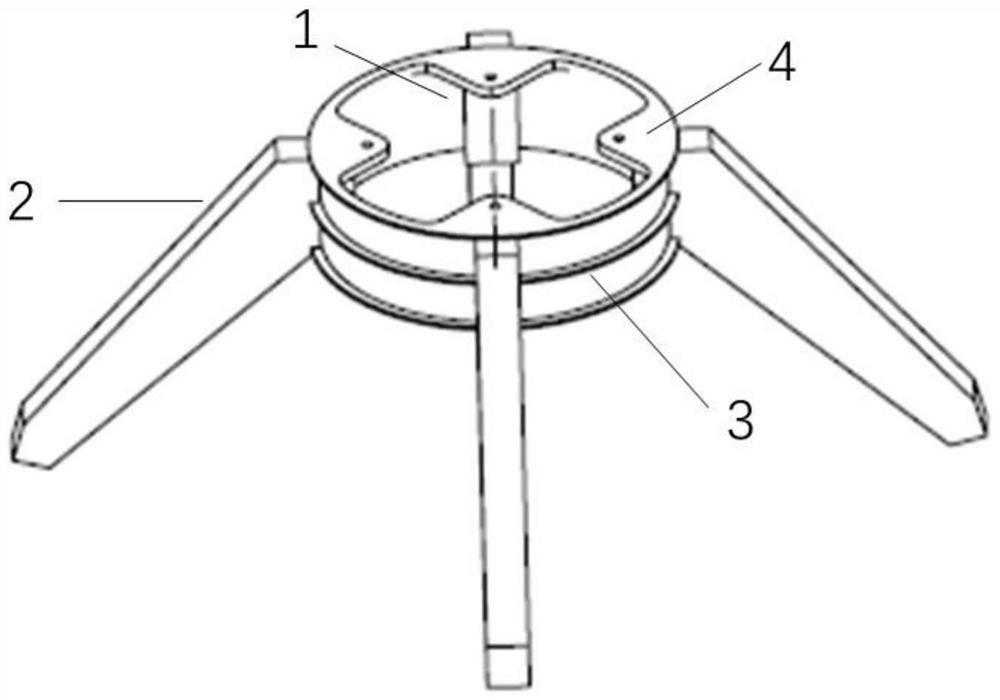

[0034] 2) Establish a finite element model of the initial body of the satellite bracket, the material is aluminum alloy, the mass is 7.0Kg, such as figure 2 , and carry out the bearing capacity analysis, it is concluded that the displacement of the bearing surface is 0.12mm under the static load of 1764N, and then the random vibration analysis is carried out. The power spectral density function of the random vibration is based on the rocket launch Based on the actual test, the real and reliable data obtained, in which the equivalent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com