Carbon nano tube composite material wrapped by carbon material as well as preparation and application of carbon nano tube composite material

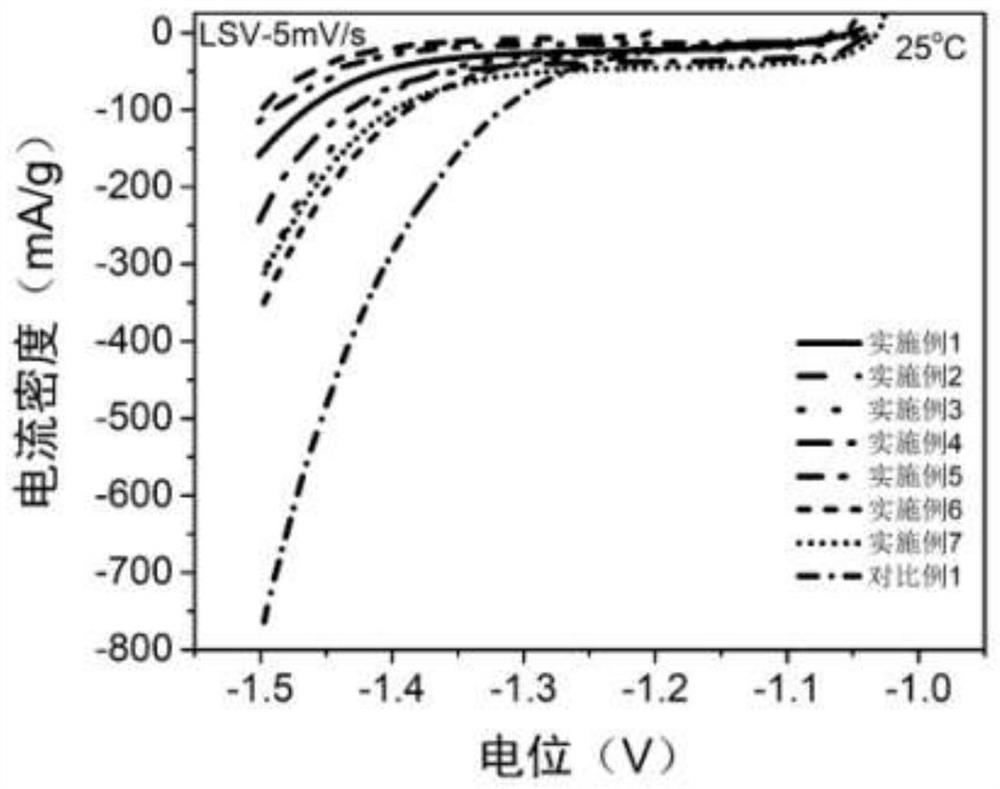

A carbon nanotube and composite material technology, which is applied in the preparation/purification of carbon, nanocarbon, active material electrodes, etc., can solve the problems of electrolyte drying, battery explosion, affecting battery life, etc., and reduce the amount of hydrogen produced. , The effect of reducing the hydrogen evolution current and reducing the peak current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1: Use the following method to prepare carbon materials-carbon nano-micro-ball composite materials:

[0023] 1) Full 10.269g sucrose to fully dissolved in 50ml ultra -pure water, and then add a 2G mass concentration of 5 % with a length of 100nm with a diameter of 10nm. In a polytimonia water heating kettle with a volume of 100ml, the water thermal kettle is transferred to 180 ° C for 12 hours at 180 ° C;

[0024] 2) 5G step 1) The solid product is made for centrifugal washing with ultra -pure water. The products obtained are scattered in a polyethylene pyrigne (PVP) solution with a mass concentration of 5 % after drying. After full stirring for 30 minutes, take the solid matter for 12 hours under 90 ° C. The carbon ball material containing carbon -carbon nanotubes with an average diameter of 3 μm;

[0025] 3) The drying product of step 2) is transferred to the N2 atmosphere environment for 5 hours under 800 ° C, and the sintered product is transferred to CO 2 The atmo...

Embodiment 2

[0031] The process is the same as the implementation example 1. The difference is that the lead carbon battery: According to the requirements of the embodiment 1, the other conditions are not changed, and the specifications of the commercial CNT are changed to 10nm and the diameter of 2nm. nanotube. The prepared electrode material analyzes the hydrogen current under -1.6V. The hydrogen current is 98.08545mA. The gas production rate of lead carbon batteries for this formula is 0.24ml / (WH · H).

Embodiment 3

[0033] The process is the same as the implementation example 1. The difference is that the lead carbon battery: according to the requirements of the embodiment 1, the specifications of the commercial CNT for the addition of the added commercial CNT are not changed. nanotube. The prepared electrode material analyzes the hydrogen current at 330.7894mA under the condition of -1.6V. The gas production rate of lead carbon batteries for this formula is 0.37ml / (WH · H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com