Preparation method of single-phase MgSiN2 powder

A powder, single-phase technology, applied in the field of preparation of single-phase magnesium silicon nitride ceramic powder, can solve the problems of ethanol volatilization loss of additives, high combustion reaction temperature, evaporation loss of magnesium powder, etc., to reduce evaporation and reaction speed. The effect of reducing and reducing evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A single-phase MgSiN 2 The preparation of powder comprises the following steps:

[0016] 1) Take by weighing 17 grams of magnesium powder with a particle size of 1 micron, 33 grams of silicon nitride powder with a particle size of 0.5 micron and α phase content of 90 wt%, and 50 grams of silicon nitride magnesium powder with a particle size of 10 microns, and use roller milling The method mixes evenly to obtain the mixed powder;

[0017] 2) Put the above-mentioned mixed powder in the porous graphite crucible of the combustion synthesis device, and feed the nitrogen-argon mixed gas after vacuuming, the pressure is 10MPa, the volume percentage of nitrogen in the mixed gas is 30%, and the ignition induces self-propagating combustion reaction;

[0018] 4) After the reaction is completed and the temperature is lowered, the product is taken out to obtain the prepared single-phase MgSiN 2 Powder.

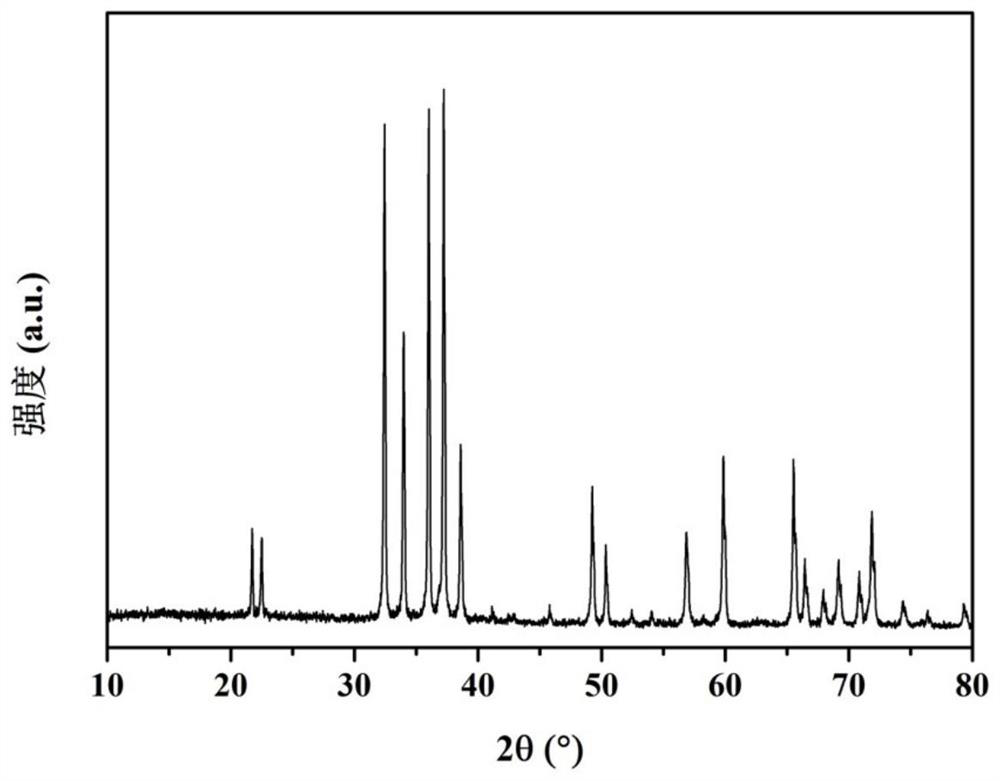

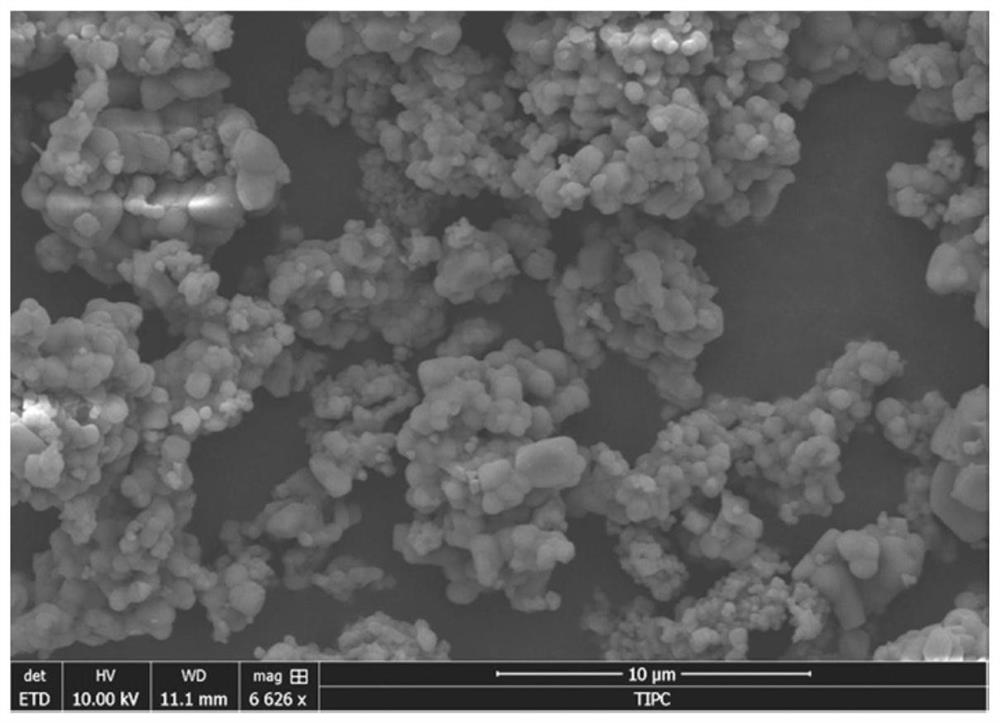

[0019] Carry out XRD phase test to the product, such as figure 1 As shown,...

Embodiment 2

[0021] A single-phase MgSiN 2 The preparation of powder comprises the following steps:

[0022] 1) Take by weighing 33 grams of magnesium powder with a particle size of 75 microns, 62 grams of silicon nitride powder with a particle size of 15 microns and α-phase content of 95 wt%, and 5 grams of silicon nitride magnesium powder with a particle size of 0.5 microns, and use roller milling The method mixes evenly to obtain the mixed powder;

[0023] 2) Put the above-mentioned mixed powder in the porous graphite crucible of the combustion synthesis device, and feed the nitrogen-argon mixed gas after vacuuming, the pressure is 1MPa, the volume percentage of nitrogen in the mixed gas is 50%, and the ignition induces self-propagating combustion reaction;

[0024] 4) After the reaction is completed and the temperature is lowered, the product is taken out to obtain the prepared single-phase MgSiN 2 Powder.

[0025] The XRD phase test was carried out on the product, and the analysis...

Embodiment 3

[0027] A single-phase MgSiN 2 The preparation of powder comprises the following steps:

[0028] 1) Take by weighing 25 grams of magnesium powder with a particle size of 45 microns, 48 grams of silicon nitride powder with a particle size of 5 microns and α-phase content of 92 wt%, and 27 grams of silicon nitride magnesium powder with a particle size of 5 microns, and use roller milling The method mixes evenly to obtain the mixed powder;

[0029] 2) Put the above-mentioned mixed powder in the porous graphite crucible of the combustion synthesis device, and feed the nitrogen-argon mixed gas after vacuuming, the pressure is 5MPa, the volume percentage of nitrogen in the mixed gas is 10%, and the ignition induces self-propagating combustion reaction;

[0030] 4) After the reaction is completed and the temperature is lowered, the product is taken out to obtain the prepared single-phase MgSiN 2 Powder.

[0031] The XRD phase test was carried out on the product, and the analysis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com