Degradable environment-friendly cinerary casket and production process thereof

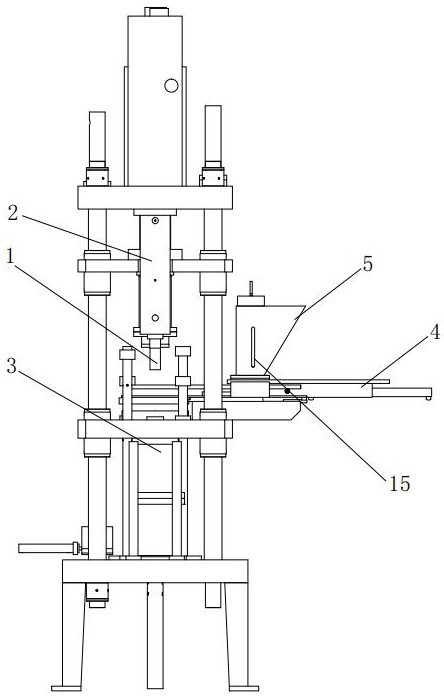

A production process and urn technology, applied in the direction of manufacturing tools, presses, material forming presses, etc., can solve the problems of inability to degrade rapidly and not environmental protection, and achieve the goal of promoting the construction of ecological civilization, saving resources and realizing scientific development. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A degradable environmental protection urn material, including: cornstarch, sorbitol, microcrystalline cellulose and glycerin, by weight percentage, wherein cornstarch is 70%, sorbitol is 20%, microcrystalline cellulose is 9% %, glycerin is 1%.

Embodiment 2

[0033] A degradable environmental protection urn material, including: cornstarch, sorbitol, microcrystalline cellulose and glycerin, by weight percentage, wherein cornstarch is 75%, sorbitol is 15%, microcrystalline cellulose is 9.5% %, glycerin is 0.5%.

Embodiment 3

[0035] A degradable environmental protection urn material, including: cornstarch, sorbitol, microcrystalline cellulose and glycerin, by weight percentage, wherein cornstarch is 72.5%, sorbitol is 17.5%, microcrystalline cellulose is 9.3% %, glycerin is 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com