Method for producing Luzhou-flavor liquor by adopting sorghum rich in beta-glucan

The technology of Luzhou-flavor liquor and glucan, which is applied in the field of winemaking, can solve the problems of weak refreshing and irritating liquor, lower total acid content, unsatisfactory effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for producing Luzhou-flavor liquor by adopting sorghum rich in β-glucan, comprising the following steps:

[0020] 1. Raw material processing

[0021] Raw material β-glucan sorghum has a content of 42g / kg (4.2%) (provided by Sichuan Huitai Agricultural Technology Co., Ltd., which is obtained by planting with the technology disclosed in the Chinese patent No. 201910030777.5). The grains are plump and fresh , no moth-eaten, mildew, no peculiar smell, no inclusions, and more than 75% of them are crushed to pass through a 20-mesh sieve;

[0022] Bran shells are fresh and clean, dry and free from mildew and odor, no more than 7% of them pass through a 20-mesh sieve, and steam for 30 minutes before use;

[0023] 2. Operation of distiller's grain ingredients and entering the cellar

[0024] Add 85Kg of β-glucan-containing sorghum to every cubic meter of distiller’s grains out of the cellar (after fermentation is complete, wait for the distiller’s grains to add bran h...

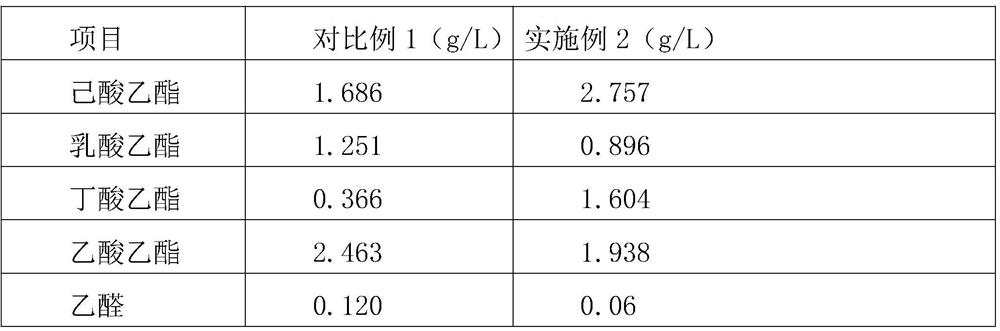

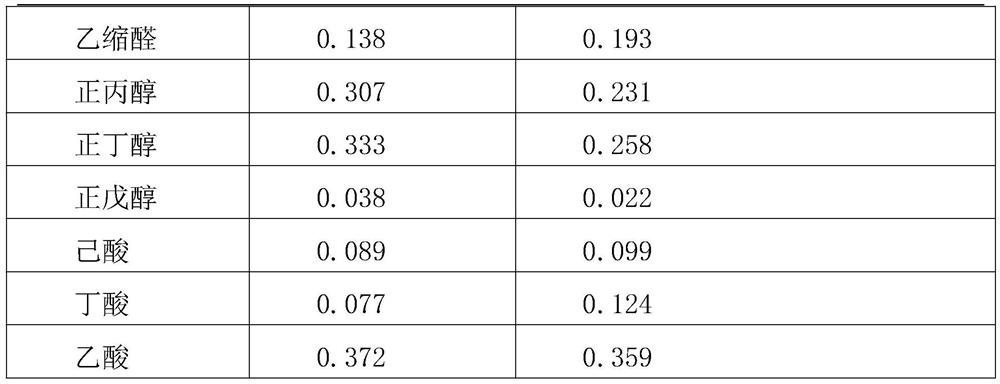

Embodiment 2

[0043] A method for producing Luzhou-flavor liquor by adopting sorghum rich in β-glucan, comprising the following steps:

[0044] 1. Raw material processing

[0045] Raw material, ordinary sorghum grains are full, fresh, free from moth-eaten, mildew, odor, and inclusions, more than 75% of which are crushed to pass through a 20-mesh sieve, and the content of β-glucan is 5g / kg (0.5%) ;

[0046] Bran shells are fresh and clean, dry and free from mildew and odor, and no more than 7% of them pass through a 20-mesh sieve, and steam for 30 minutes before use;

[0047] 2. Operation of distiller's grain ingredients and entering the cellar

[0048]Add 85Kg of ordinary sorghum, 1600g of β-glucan (purchased from Saiqi Biology), 20Kg of bran husks for every cubic meter of distiller’s grains out of the cellar (after fermentation is completed, wait for grain addition, bran husks, and steamed distiller’s grains), mix well, and steam the wine , measure 65Kg of water in every cubic meter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com