Ultrahigh-temperature long-service-life thermal barrier coating material and preparation method of ultrahigh-temperature long-service-life thermal barrier coating

A thermal barrier coating and long-life technology, applied in coatings, chemical instruments and methods, metal material coating technology, etc., can solve problems such as not being used, achieve long life, high-temperature phase stability, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

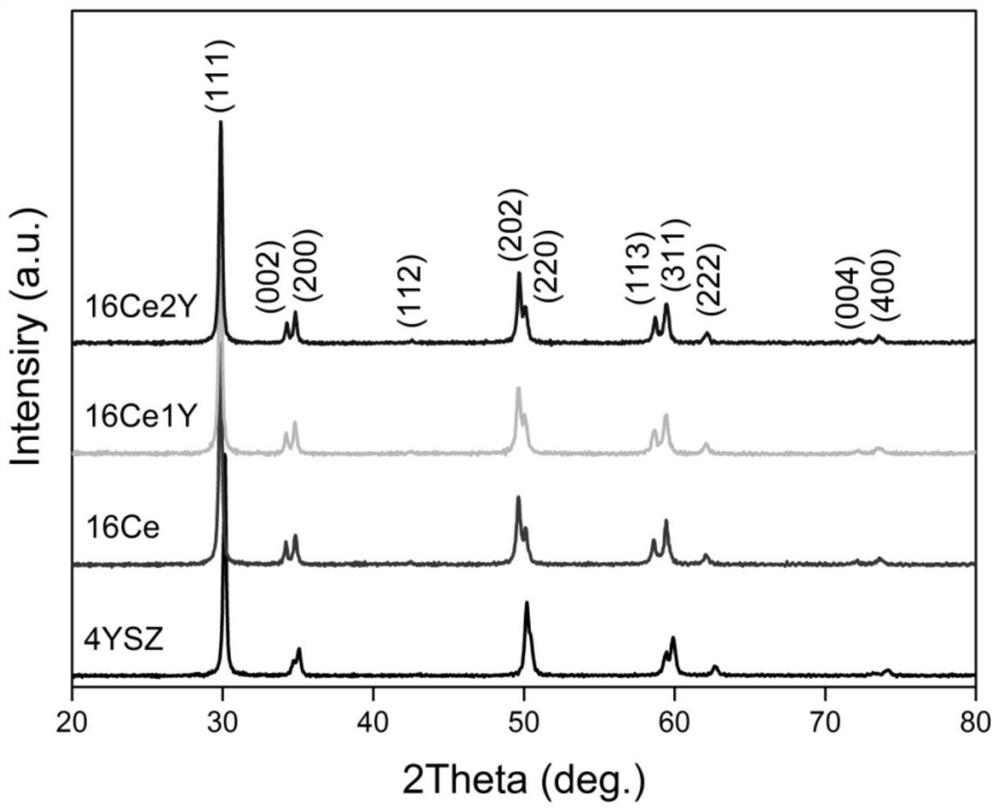

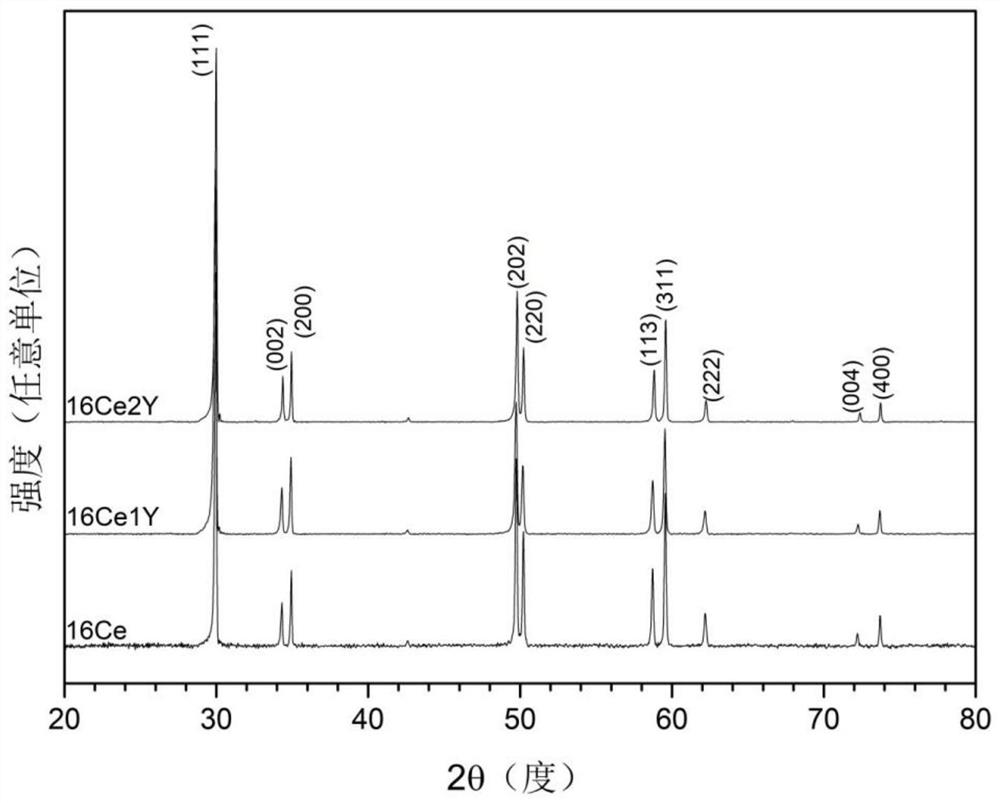

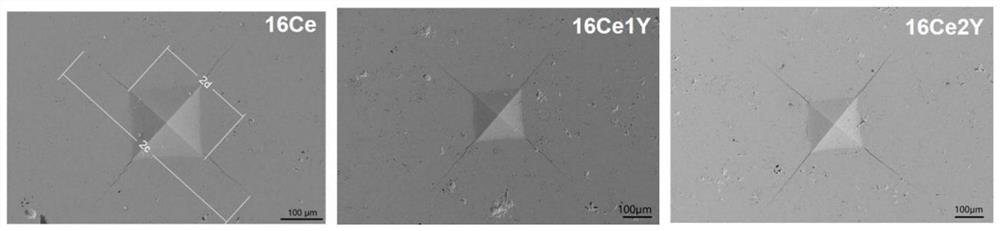

[0033] An ultra-high temperature and long-life thermal barrier coating material, the chemical composition of the thermal barrier coating material is (Zr 0.84 Ce 0.16 )O 2 , (referred to as 16Ce);

[0034] The preparation method of the thermal barrier coating material is: Zr(NO 3 ) 4 ·3H2 O, Ce(NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O: Ce(NO 3 ) 3 ·6H 2 O=0.84:0.16 Weighing, prepare the aqueous solution whose total energy concentration of metal ions is 0.1mol / L, add additive citric acid, polyethylene glycol, its addition amount is respectively 50 grams / liter, 30 grams / liter, magnetic stirring 0.5 Hour obtains clear and transparent sol;

[0035] Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture, and the precursor of the ultra-high temperature and long-life thermal barrier coating material was obtained. ...

Embodiment 2

[0037] An ultra-high temperature and long-life thermal barrier coating material, the chemical composition of the thermal barrier coating material is (Zr 0.83 Y 0.01 Ce 0.16 )O 2 , (referred to as 16Ce1Y);

[0038] The preparation method of the thermal barrier coating material is: Zr(NO 3 ) 4 ·3H 2 O, Y (NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O: Ce(NO 3 ) 3 ·6H 2 O=0.83:0.01:0.16 Weighing, preparation of an aqueous solution with a total energy concentration of metal ions of 0.1mol / L, adding additives citric acid and polyethylene glycol, the addition amount is 50 g / L and 30 g / L respectively, magnetic Stir for 0.5 hour to obtain a clear and transparent sol;

[0039] Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture, and the precursor of the ultra-high temperature and long-life t...

Embodiment 3

[0041] An ultra-high temperature and long-life thermal barrier coating material, the chemical composition of the thermal barrier coating material is (Zr 0.82 Y 0.02 Ce 0.16 )O 2 , (referred to as 16Ce1Y);

[0042] The preparation method of the thermal barrier coating material is: Zr(NO 3 ) 4 ·3H 2 O, Y (NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O: Ce(NO 3 ) 3 ·6H 2 O=0.82:0.02:0.16 Weighing, preparing an aqueous solution with a total energy concentration of metal ions of 0.1mol / L, adding additives citric acid and polyethylene glycol, the amount of which is 50 g / L and 30 g / L respectively, magnetic Stir for 0.5 hour to obtain a clear and transparent sol;

[0043] Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture, and the precursor of the ultra-high temperature and long-life therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com