Long-life t '-YSZ-based phosphorescent temperature measurement coating material and preparation method of temperature measurement coating

A coating material and long-life technology, applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of not meeting the requirements of gas turbines, insufficient temperature resistance of coatings, differences, etc., to improve the bearing temperature Temperature measurement ability, strong luminous intensity, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

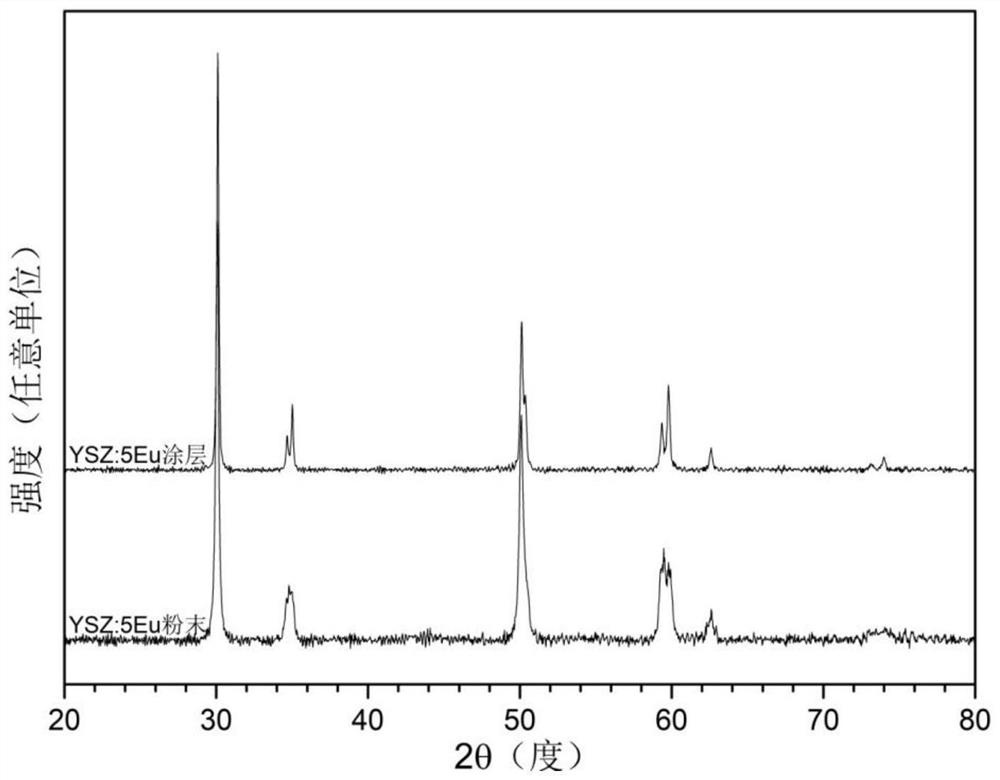

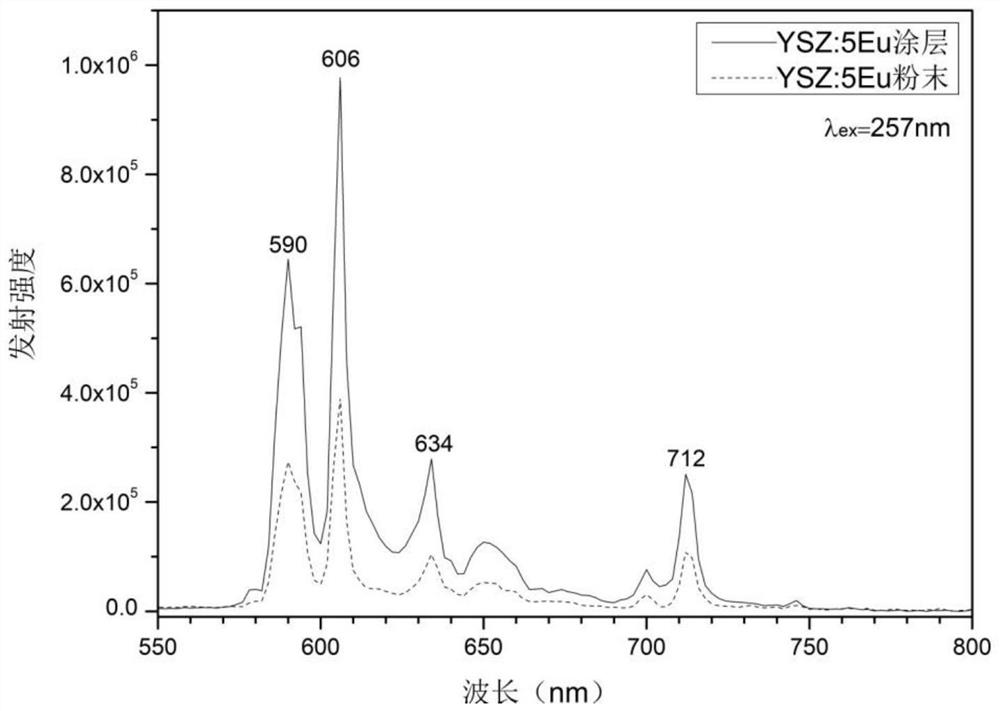

[0030] A long-life t′-YSZ-based phosphorescent temperature-measuring coating material, the chemical composition of the temperature-measuring coating material is Zr 0.913 Y 0.037 Eu 0.05 o 1.9565 , (referred to as YSZ:5Eu for short);

[0031] The preparation method of the temperature-measuring coating material is: Zr(NO 3 ) 4 ·3H 2 O, Y (NO 3 ) 3 ·6H 2 O, Eu(NO 3 ) 3 ·6H2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O:Eu(NO 3 ) 3 ·6H 2 O=0.913:0.037:0.05, weighing, preparation metal ion total energy concentration is the aqueous solution of 0.1mol / L, adds additive citric acid, polyethylene glycol, and its addition is respectively 50 grams / liter, 30 grams / liter, Magnetically stirred for 0.5 hours to obtain a clear and transparent sol, using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, atomizing the sol into a corundum crucible at a temperature of 400°C to quickly remove moisture, and obtain the lon...

Embodiment 2

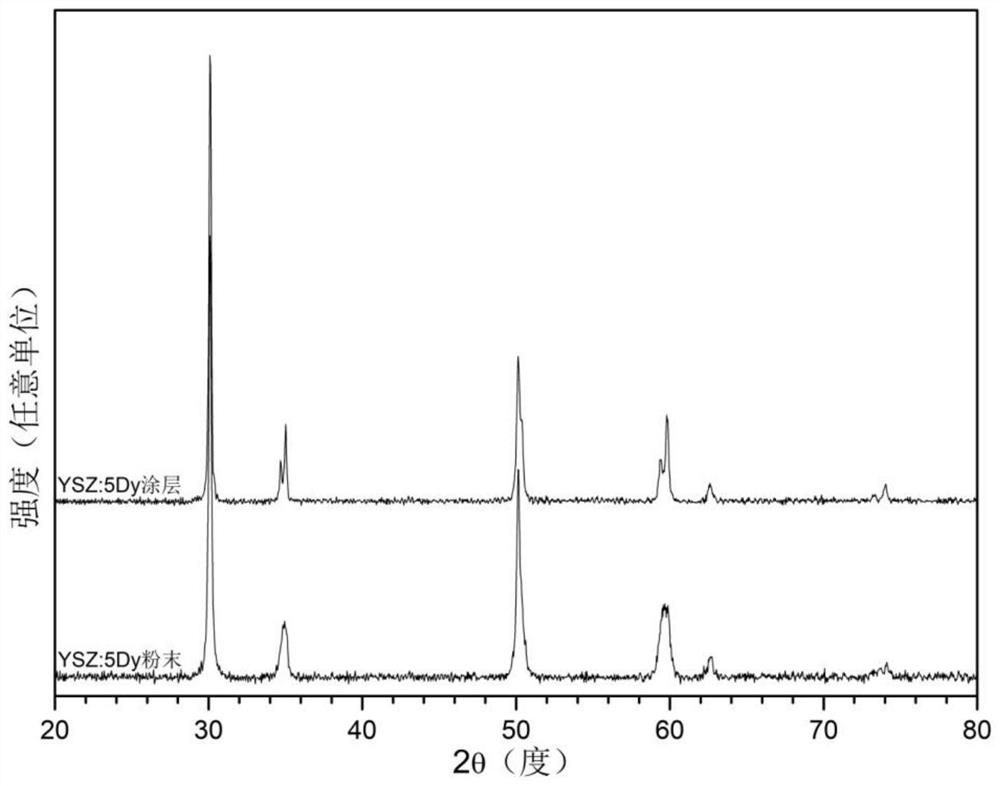

[0051] A long-life t′-YSZ-based phosphorescent temperature-measuring coating material, the chemical composition of the temperature-measuring coating material is Zr 0.913 Y 0.037 Dy 0.05 o 1.9565 , (referred to as YSZ:5Dy);

[0052] The preparation method of the temperature-measuring coating material is: Zr(NO 3 ) 4 ·3H 2 O, Y (NO 3 ) 3 ·6H 2 O, Dy(NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O:Dy(NO 3 ) 3 ·6H 2 O=0.913:0.037:0.05, weighing, preparation metal ion total energy concentration is the aqueous solution of 0.1mol / L, adds additive citric acid, polyethylene glycol, and its addition is respectively 50 grams / liter, 30 grams / liter, Magnetically stirred for 0.5 hours to obtain a clear and transparent sol, using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, atomizing the sol into a corundum crucible at a temperature of 400°C to quickly remove moisture, and obtain the long-life t...

Embodiment 3

[0062] A long-life t′-YSZ-based phosphorescent temperature-measuring coating material, the chemical composition of the temperature-measuring coating material is Zr 0.913 Y 0.057 T m 0.03 o1.9565 (referred to as YSZ:3Tm);

[0063] The preparation method of the temperature-measuring coating material is: Zr(NO 3 ) 4 ·3H 2 O, Y (NO 3 ) 3 ·6H 2 O, Tm (NO 3 ) 3 ·6H 2 O is the raw material, in molar ratio Zr(NO 3 ) 4 ·3H 2 O:Y(NO 3 ) 3 ·6H 2 O:Tm(NO 3 ) 3 ·6H 2 O=0.913:0.057:0.03, weighing, preparation metal ion total energy concentration is the aqueous solution of 0.1mol / L, adds additive citric acid, polyethylene glycol, and its addition is respectively 50 grams / liter, 30 grams / liter, Magnetically stirred for 0.5 hours to obtain a clear and transparent sol. Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture, and the ultra-high temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com