A kind of neodymium-cerium composite zirconate thermal barrier coating material with ultra-low thermal conductivity and high-temperature phase stability and its preparation method

A technology of compounding zirconate and thermal barrier coating, which is applied in the field of thermal barrier coating, can solve the problem that the field of thermal barrier coating has not been paid attention to, and achieves improved thermal insulation effect, simple preparation method, high and high temperature phase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] According to one aspect of the present invention, the preparation method of the above-mentioned neodymium-cerium composite zirconate thermal barrier coating material is characterized in that it comprises:

[0034] With a purity of 99.99% Nd(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O is raw material, by mole ratio Nd(NO 3 ) 3 ·6H 2 O: Ce(NO 3 ) 3 ·6H 2 O:Zr(NO 3 ) 4 ·3H 2 O=(0.2-0.8): (0.2-0.8): 1 Weighing, prepare an aqueous solution with a total concentration of metal ions of 0.1mol / L, add additives citric acid and polyethylene glycol, and the addition amount is 50 grams / liter respectively , 30 g / L, magnetically stirred until a clear and transparent sol,

[0035] Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at 400°C to quickly remove moisture to obtain the precursor of the neodymium-cerium composite zirconate thermal barrier coating material, and then ...

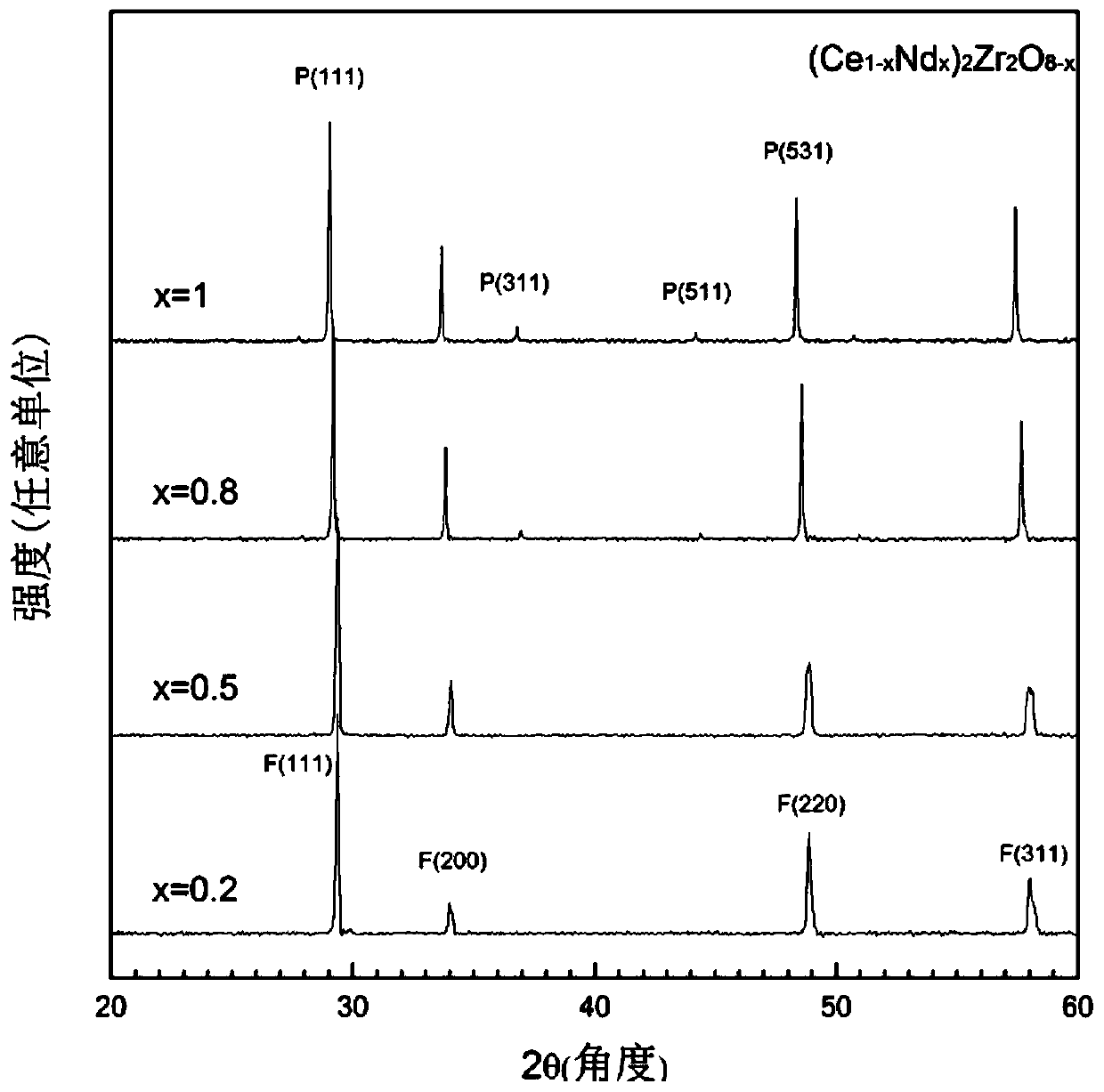

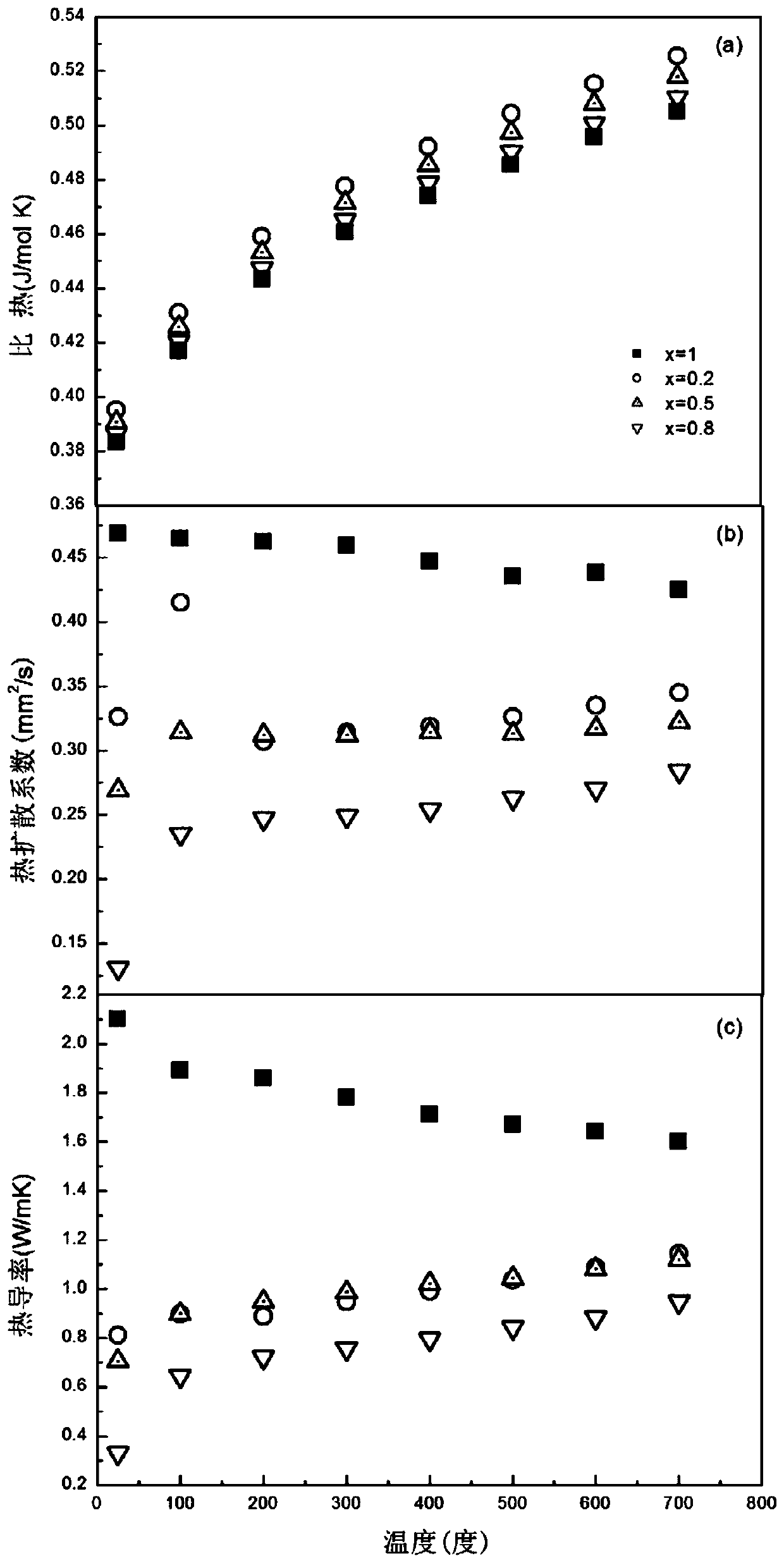

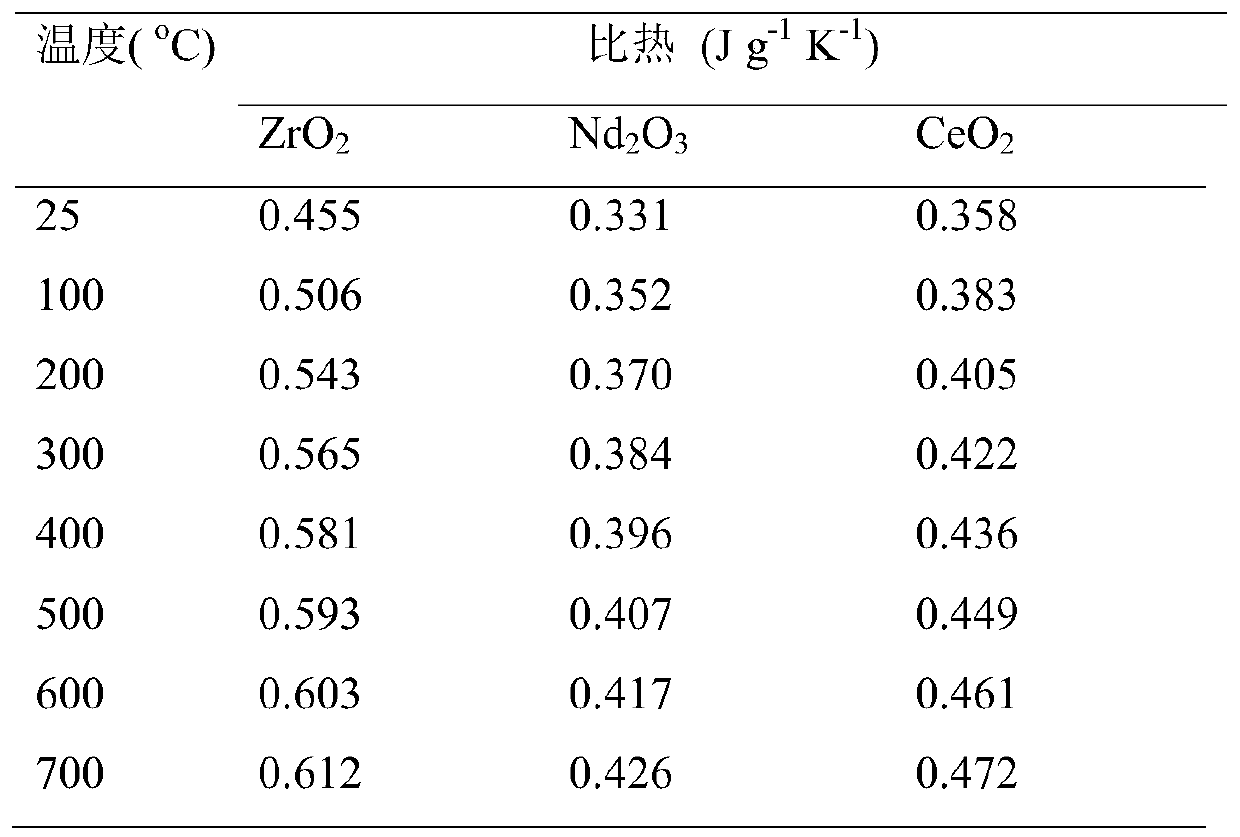

Embodiment 1

[0038] With a purity of 99.99% Nd(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O is raw material, by mole ratio Nd(NO 3 ) 3 ·6H 2 O: Ce(NO 3 ) 3 ·6H 2 O: Zr(NO 3 ) 4 ·3H 2 O=0.2:0.8:1 Weighing, preparing an aqueous solution with a total concentration of metal ions of 0.1mol / L, adding additives citric acid and polyethylene glycol, the addition amounts are 50 g / L and 30 g / L respectively, and magnetic stirring After 0.5 hours, a clear and transparent sol was obtained.

[0039] Using air with a purity of 99.99% and a pressure of 0.1 MPa as the atomizing medium, the sol was atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture, and then calcined in an air atmosphere at 1200°C for 6 hours and then cooled to room temperature to obtain (Ce 0.8 Nd 0.2 ) 2 Zr 2 o 7.8 powder.

[0040] Put the above-mentioned synthesized powder into an agate mortar for grinding, take an appropriate amount and put it into a stainless steel...

Embodiment 2

[0048] With a purity of 99.99% Nd(NO 3 ) 3 ·6H 2 O, Ce(NO 3 ) 3 ·6H 2 O, Zr(NO 3 ) 4 ·3H 2 O is raw material, by mole ratio Nd(NO 3 ) 3 ·6H 2 O: Ce(NO 3 ) 3 ·6H 2 O: Zr(NO 3 ) 4 ·3H 2 O=0.5:0.5:1 Weighing, preparing an aqueous solution with a total concentration of metal ions of 0.1mol / L, adding additives citric acid and polyethylene glycol, the addition amounts are 50 g / L and 30 g / L respectively, and magnetically stirred After 0.5 hours, a clear and transparent sol was obtained.

[0049] Using air with a purity of 99.99% and a pressure of 0.1MPa as the atomizing medium, the sol is atomized into a corundum crucible at a temperature of 400°C to quickly remove moisture to obtain a precursor, which is then calcined in an air atmosphere at 1200°C for 6 hours and then cooled. to room temperature, obtain (Ce 0.5 Nd 0.5 ) 2 Zr 2 o 7.5 powder.

[0050] Put the above-mentioned synthesized powder into an agate mortar for grinding, take an appropriate amount and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com