Processing technology of electrolytic aluminum

A processing technology and electrolytic aluminum technology, applied in the field of electrolytic aluminum processing, can solve the problems of blockage of filter mesh, prolong filtration time, reduce filtration efficiency, etc., and achieve the effect of preventing blockage, improving operation performance, and reducing operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

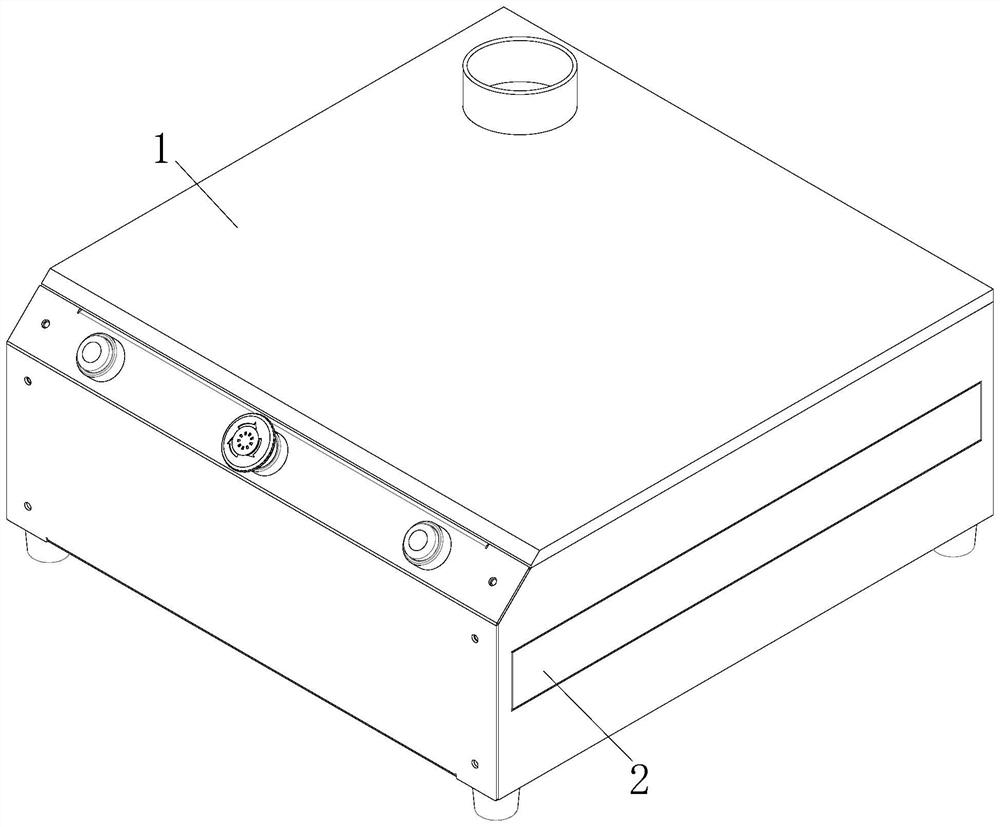

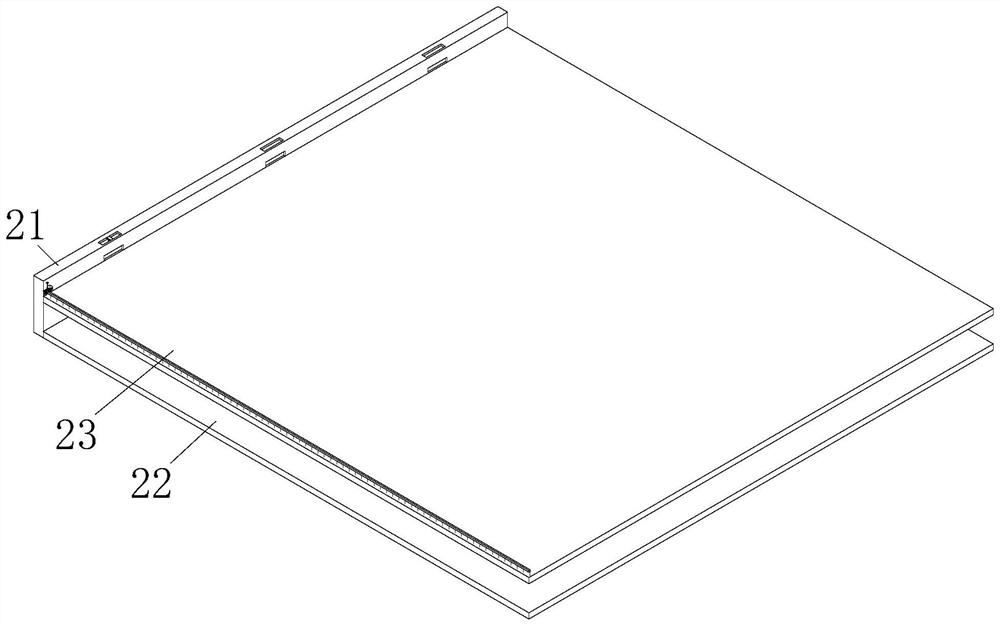

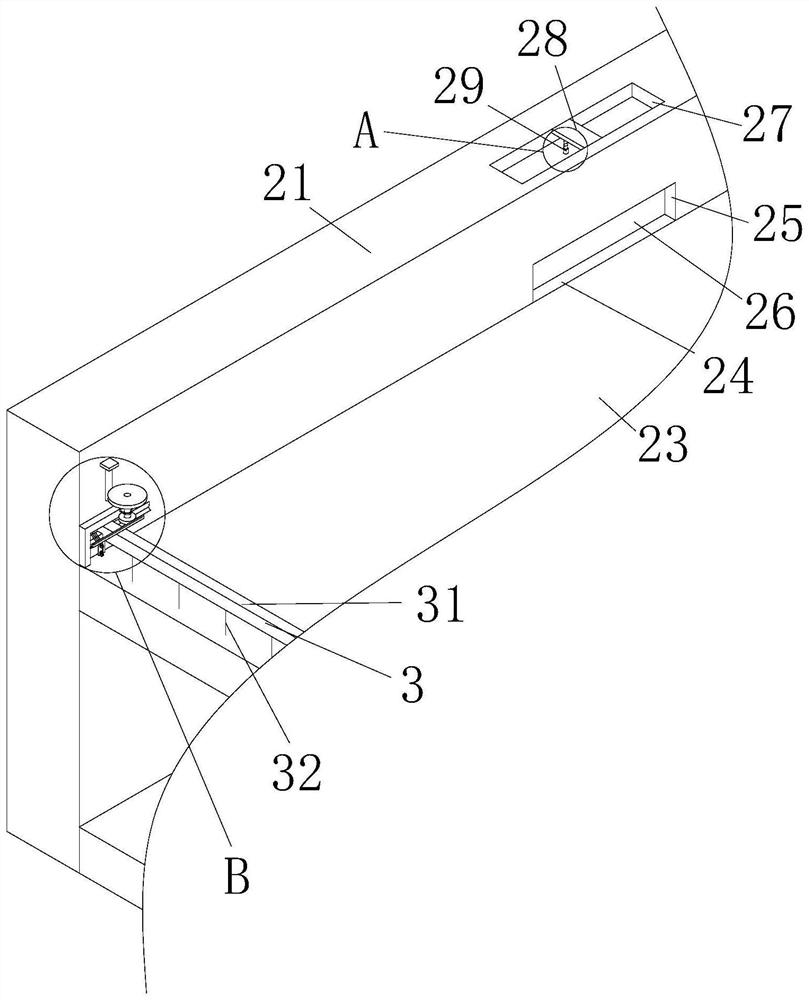

[0036] Attached below Figure 1-7 The present invention is further described with embodiment:

[0037] A processing technology for electrolytic aluminum, comprising the steps of:

[0038] A. Mix electrolytes other than alumina, cryolite is used as a solvent for electrolytic reaction alumina, dissolve alumina in cryolite, heat the electrolyte mixture except alumina until it is molten, and then add ice crystals containing alumina stone solution to obtain a melt;

[0039] B. Connect the electrodes of the electrolytic cell to the power supply, place the melt obtained in step A in the electrolytic cell and perform electrolysis at 800-820°C with a current density of 1A / cm2 to obtain electrolytic aluminum liquid;

[0040]C. The molten aluminum obtained in step B is stirred and filtered to remove impurities including slag in the molten aluminum to obtain pure aluminum for packaging. In the present invention, the structure of the existing filtering device is improved, and the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com