Vacuum electron beam cold hearth smelting furnace system capable of reducing evaporation coatings

A vacuum electron beam and cooling bed melting technology, which is applied in furnaces, coatings, crucible furnaces, etc., can solve the problems affecting the quality of material casting and hindering the mass production of materials, so as to reduce the production process time, slow down the formation rate, reduce effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

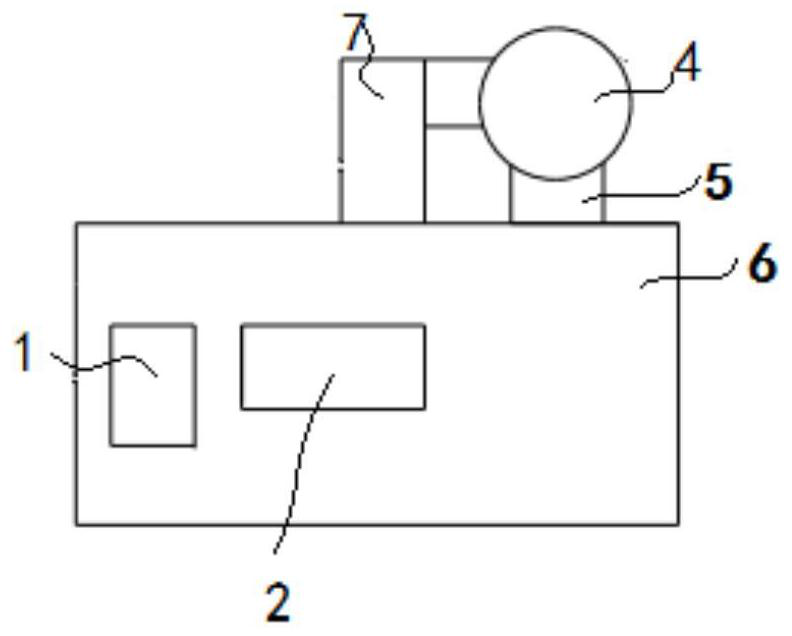

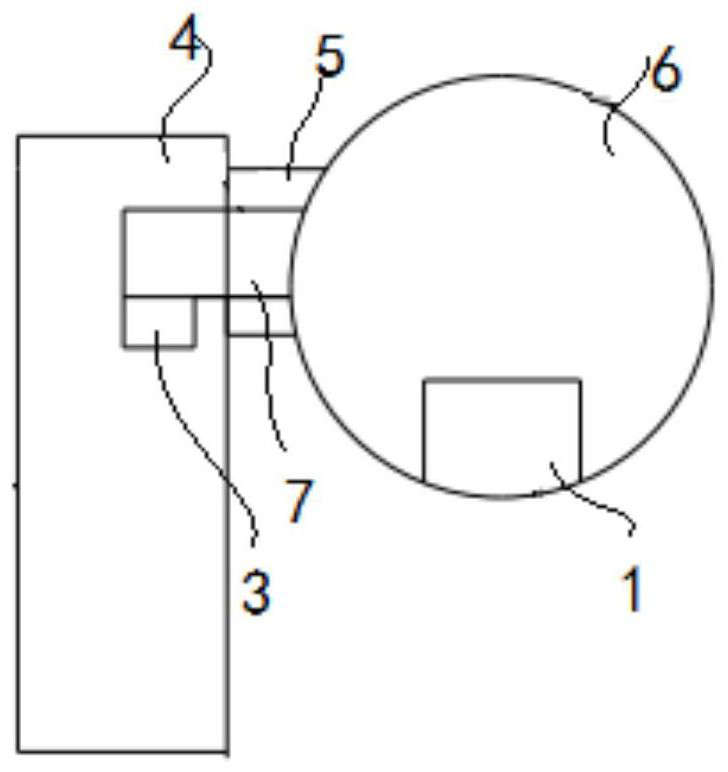

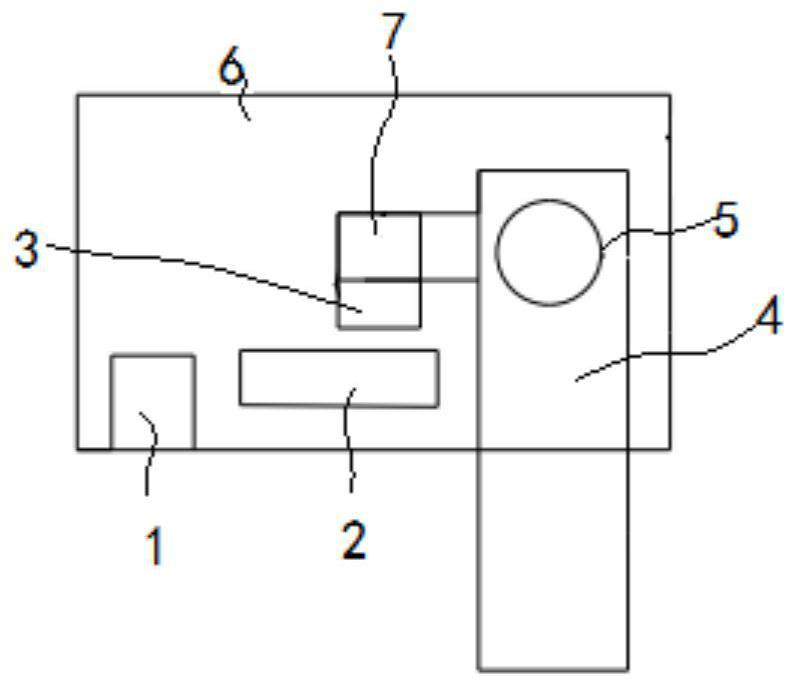

[0041] Such as Figure 1-3 Among them, this embodiment provides a vacuum electron beam cooling bed melting furnace system for reducing evaporation coating, including a melting unit, a vacuum pumping unit and a pumping material unit.

[0042] Specifically, the smelting unit includes a casting crucible 1 , a horizontal crucible 2 , and an EB furnace body 6 . The EB furnace body is provided with a casting crucible 1 and a horizontal crucible 2; on the outer surface of the end of the EB furnace body 6 away from the casting crucible 1, a vacuum port is provided; the EB furnace body 6 is located above the horizontal crucible 2, close to the diffusion pump The wall on one side of 4 is provided with an evaporation material extraction port.

[0043] The vacuum pumping unit includes a diffusion pump 4, and the EB furnace body 6 communicates with the diffusion pump 4 through a vacuum pumping pipeline 5;

[0044] The evaporating material extraction unit includes a sinking powder chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com