Positioning detection method of hot-formed workpieces in ultra-high-strength steel hot stamping production line

A positioning detection and production line technology, which is applied in image enhancement, computer parts, image analysis, etc., can solve problems such as production downtime and inadequate observation, and achieve the effects of reducing mold damage, saving labor costs, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those in the art of the present invention to better understand the technical solution in the present invention, the following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only part of the embodiments of the present invention, not all embodiments.

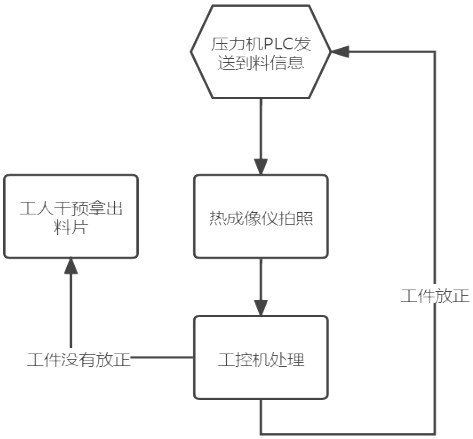

[0042] combine Figure 1 , a kind of positioning detection method for thermoformed workpieces in ultra-high strength rigid hot stamping production line, including the following steps:

[0043] A. Generate a positioning template

[0044] The use of thermal imager to shoot the heat map image of the raw material normally placed on the press mold after heating, the image is transmitted to the industrial computer of the press through industrial Ethernet, and the image recognition algorithm software on the industrial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com