Aldehyde alcohol condensation reaction device

An aldol condensation and reaction device technology, applied in the field of aldol condensation reaction devices, can solve problems such as larger device scale, poor thermal efficiency, consumption, etc., and achieves expansion of equipment scale, miniaturization of required costs, and reduction of conversion rate high effect

Pending Publication Date: 2022-05-13

韩华思路信株式会社

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, the means of continuously circulating the reactants while using the heat exchanger to control the temperature to the desired temperature has been used, but this method has the disadvantages of poor thermal efficiency due to the consumption of a large amount of additional heat energy, and the scale of the device becomes large and complicated.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

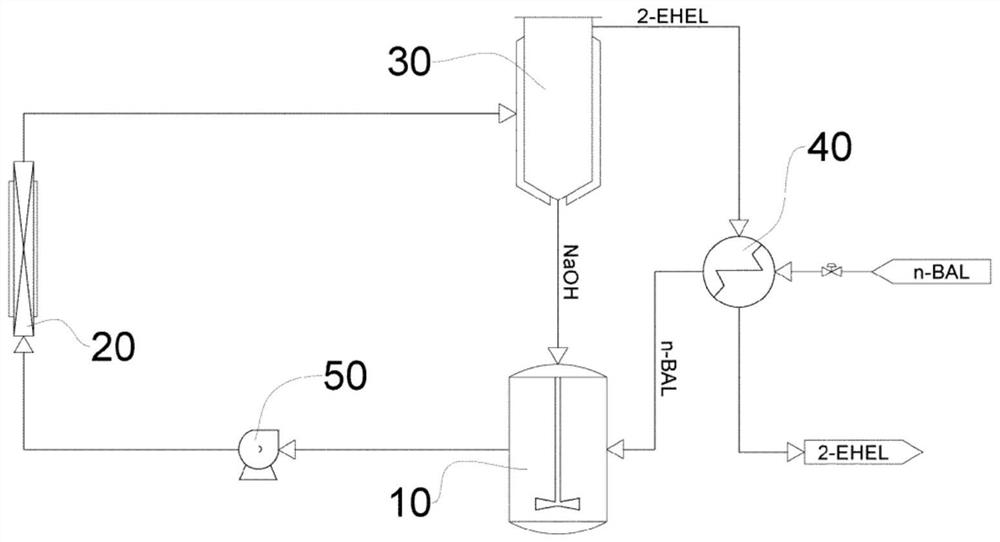

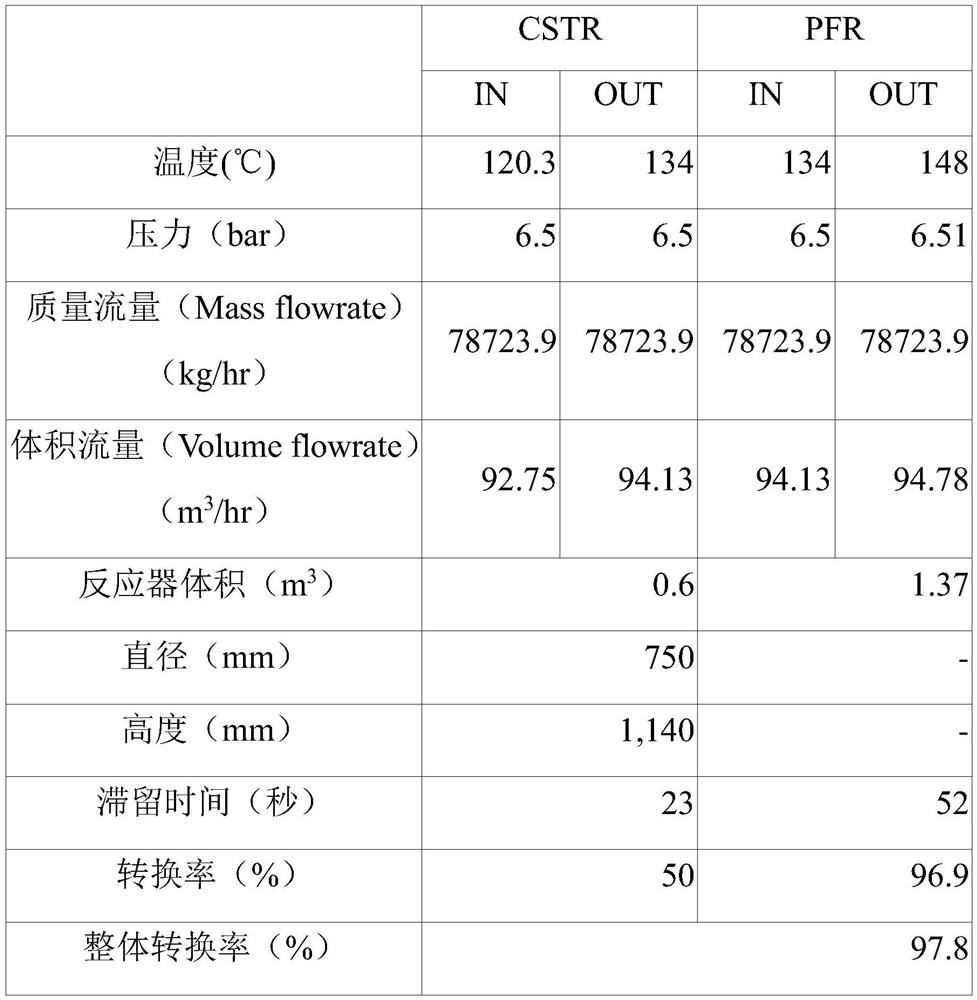

[0053] designed as figure 1 2-ethylhexenal was produced from n-butyraldehyde by an aldol condensation reaction under the conditions of the following Table 1 in the reaction apparatus shown in the process diagram of , and the conversion rate was measured.

[0054] At this time, the catalyst circulated through the oil-water separator 30 is not mixed with the reactants, but directly flows into the continuous stirred tank reactor 10 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The aldol condensation reaction device according to the present invention brings high productivity at a low cost, and particularly, the aldol condensation reaction device according to the present invention has the effect of preventing a decrease in conversion rate due to an increase in residence time when the scale of the device is expanded, thereby bringing high productivity. In addition, the present invention has the effects of achieving conditions for increasing the concentration and temperature of the catalyst and minimizing the use content of the catalyst at the same yield as in the prior art. Furthermore, the present invention has the effect of minimizing the cost required by enlarging the scale of equipment and minimizing the amount of harmful waste water generated without additionally adding a device such as a pump.

Description

technical field [0001] The invention relates to an aldol condensation reaction device. Background technique [0002] Usually the aldol condensation reaction refers to: through the hydroformylation (hydroformylation) reaction called oxo synthesis (OXO) reaction, in the presence of metal catalysts and ligands, various alkenes and synthetic gas (synthetic gas, CO / H 2 ) to react to generate a linear or branched aldehyde with one or more carbon atoms added to the olefin, and then generate an α, β unsaturated aldehyde through an aldol condensation reaction. [0003] The unsaturated aldehydes synthesized after the condensation reaction of aldol (Aldol) etc. can be converted into various acids or alcohols containing long-chain alkyl groups through oxidation or reduction reactions. Such alcohols or acids are used as solvents, additives, and various enhancers. Used as raw materials for plastics, etc. [0004] In order to improve the existing aldol condensation reaction, in the tec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J19/00B01J19/18B01J8/00C07C45/45C07C47/21B01D17/02

CPCB01J19/00B01J19/18B01J8/008B01J8/00B01J19/0046C07C45/45B01J19/0006B01D17/02B01J2219/0059B01J2219/00495B01J2219/00006C07C47/21C07C45/74C07C47/02B01J35/27B01J19/0013B01J19/0066B01J19/248B01J23/04B01J2219/00033B01J2219/00063B01J2219/00103B01J2219/00166C07C45/80

Inventor 李信范全孝镇郑景先韩基道韩俊熙

Owner 韩华思路信株式会社

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com