Multi-purpose digital ray automatic detection method

An X-ray and X-ray machine technology, applied in the field of linked X-ray digital flat-panel detection devices, can solve the problems of difficult installation and debugging, small detection range of steel pipes, and inability to detect small-diameter steel pipes, so as to save protection costs and equipment costs, The equipment maintenance is convenient and simple, and the detection is stable and efficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

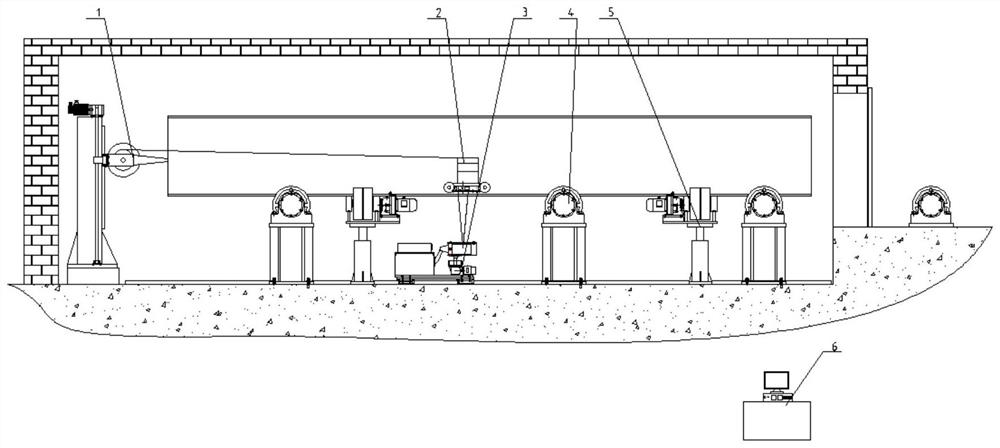

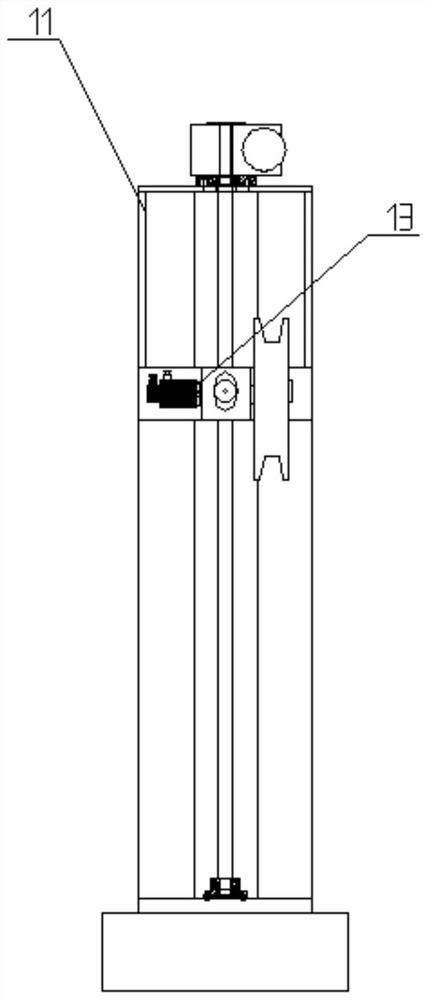

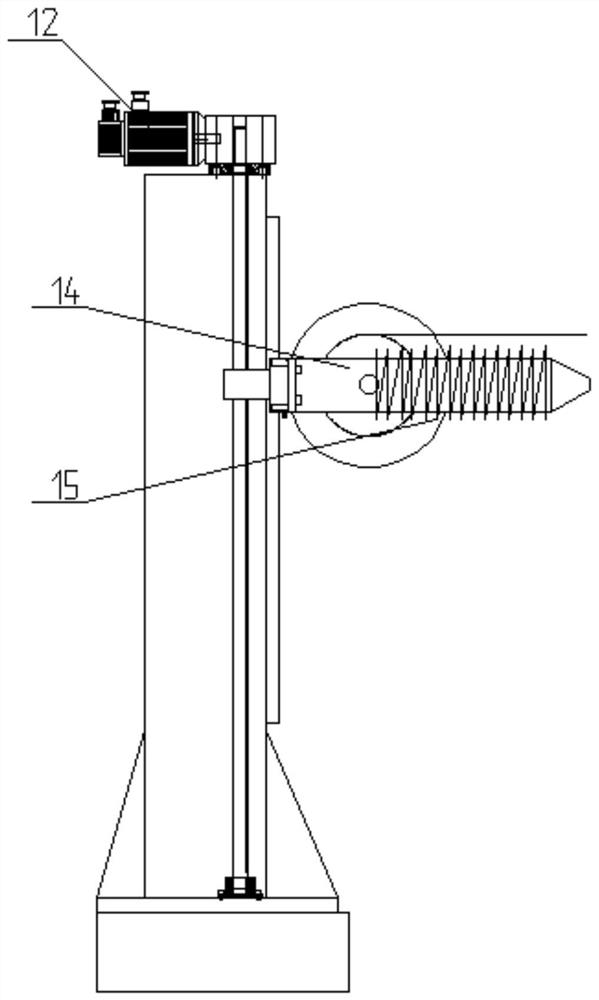

[0039] Such as Figure 1-Figure 8 A linkage type straight welded steel pipe X-ray digital flat-panel inspection device is shown, which is characterized by: including: climbing car fixing frame 1, walking imager climbing car 2, mobile lifting ray machine device 3, split conveyor roller table 4, The lifting and rotating track 5, the system console 6, the climbing car fixing frame 1 is set at the rear end of the detection room, the front end of the climbing car fixing frame 1 is connected with a walking imager climbing car 2, and the mobile lifting ray machine device 3 is set in the middle of the testing room On the ground track, you can move forward. The split conveying roller table 4 is placed at intervals in the center of the testing room. The lifting and rotating track 5 is placed in the middle of the split conveying roller table 4. The system console 6 is set outside the testing room. After the system console 6 feeds back and summarizes the information, it sends a drive cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com