Preparation method of lithium battery diaphragm adopting VDF polymer water-based coating liquid

A lithium battery diaphragm and water-based coating solution technology, which is applied in the direction of lithium batteries, non-aqueous electrolyte batteries, battery components, etc., can solve the problems of difficult production, high cost, and complicated equipment, and is conducive to industrialization. Promotion, The effect of low production cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

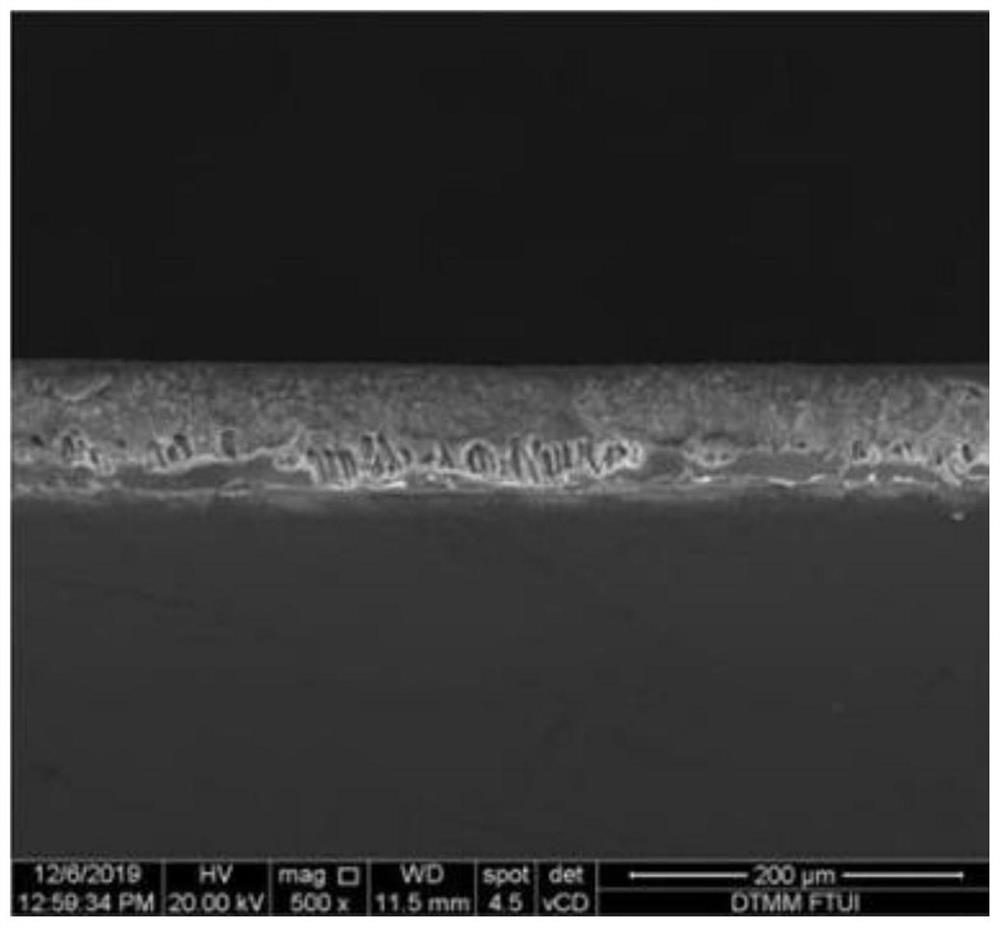

[0039] Using polyethylene film and coating VDF polymer lithium battery separator coating liquid on both surfaces of the film, the coating rate is 5m / min, and drying in a 60°C oven to obtain a lithium battery separator.

[0040] The preparation method of VDF polymer coating liquid for lithium battery separator is as follows:

[0041] (1) 100 g of polyvinylidene fluoride emulsion was added to 30 g of potassium hydroxide solution with a concentration of 20%, nitrogen was introduced, and heated and stirred at 60° C. for 5 h to obtain a polyvinylidene fluoride emulsion with carbon-carbon double bonds on the molecular chain;

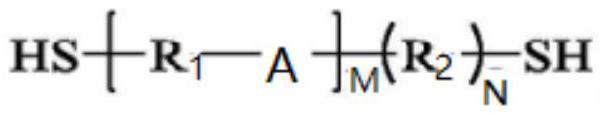

[0042] (2) Add 100g of carbon-carbon double bond polyvinylidene fluoride emulsion, 10g of thiodiethylene mercaptan, 2g of vinyltributanone oximosilane, 0.02g of lithium acrylate, 0.5g of 2-hydroxy-2 into the reactor -Methyl-1-phenylacetone, mix uniformly, and age at 60° C. for 16 hours to obtain a VDF polymer lithium battery separator coating solution.

[004...

Embodiment 2

[0045] Using polypropylene film and coating VDF polymer lithium battery separator coating liquid on both sides of the film at a coating rate of 5 m / min, and drying in a 60° C. oven to obtain a lithium battery separator.

[0046] The preparation method of VDF polymer coating liquid for lithium battery separator is as follows:

[0047](1) 100 g of vinylidene fluoride-hexafluoropropylene emulsion was added to 30 g of potassium hydroxide solution with a concentration of 20%, nitrogen was introduced, and heated and stirred at 60 ° C for 5 h to obtain vinylidene fluoride- Hexafluoropropylene emulsion;

[0048] (2) Add 100g of carbon-carbon double bond vinylidene fluoride-hexafluoropropylene emulsion, 12g of ethanedithiol, 3g of vinyltributanone oximosilane, 0.03 part of lithium acrylate, 1.0g of 1-hydroxyl ring in the reactor Hexyl phenyl ketone, mixed uniformly, and aged at 65° C. for 16 h to obtain a VDF polymer lithium battery separator coating solution.

[0049] (3) When coati...

Embodiment 3

[0051] A polyethylene / polypropylene composite film was used and the VDF polymer lithium battery separator coating liquid was coated on both sides of the film at a coating rate of 5 m / min, and dried in an oven at 60°C to obtain a lithium battery separator.

[0052] The preparation method of VDF polymer coating liquid for lithium battery separator is as follows:

[0053] (1) 100 g of vinylidene fluoride-trifluoroethylene emulsion was added to 30 g of potassium hydroxide solution with a concentration of 20%, nitrogen was introduced, and heated and stirred at 60 ° C for 5 h to obtain vinylidene fluoride- trifluoroethylene emulsion;

[0054] (2) in the reactor, add the vinylidene fluoride-trifluoroethylene emulsion of 100g carbon-carbon double bond, 16g ethanedithiol, 4g vinyltributanone oximosilane, 0.04 part of lithium acrylate, 1.5g 2,4, 6-trimethylbenzoyl-diphenylphosphine oxide, mixed uniformly, and aged at 70° C. for 12 hours to obtain a VDF polymer lithium battery separator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com