Water-based PVDF coated lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and coating technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of uneven distribution of PVDF resin powder, affecting the performance of lithium-ion batteries, and increasing the thickness of the coating, achieving improved Rate discharge performance and cycle performance, which is conducive to industrialization and the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

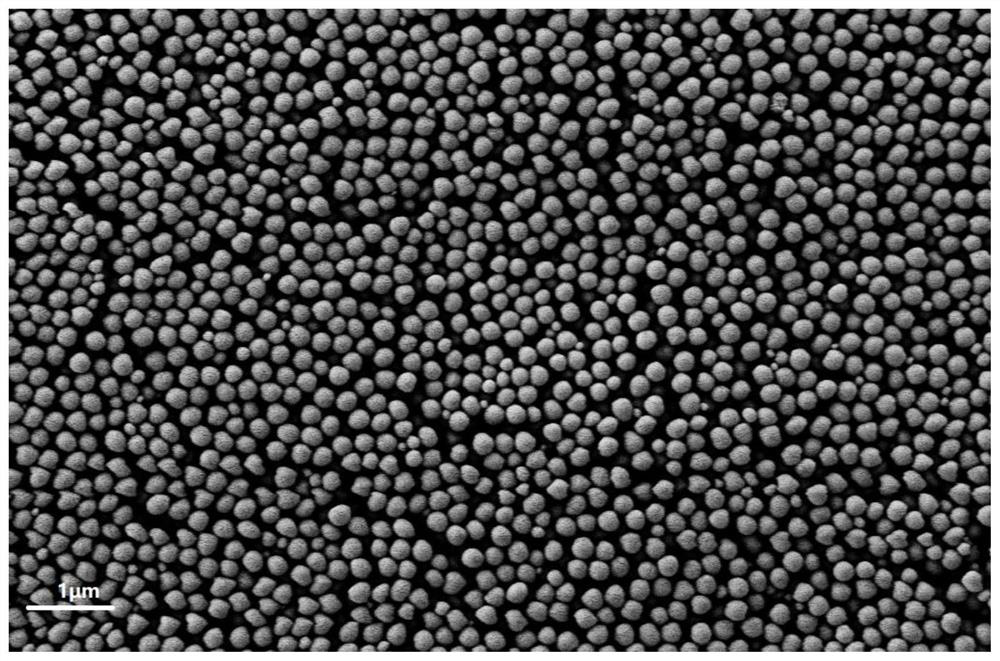

Image

Examples

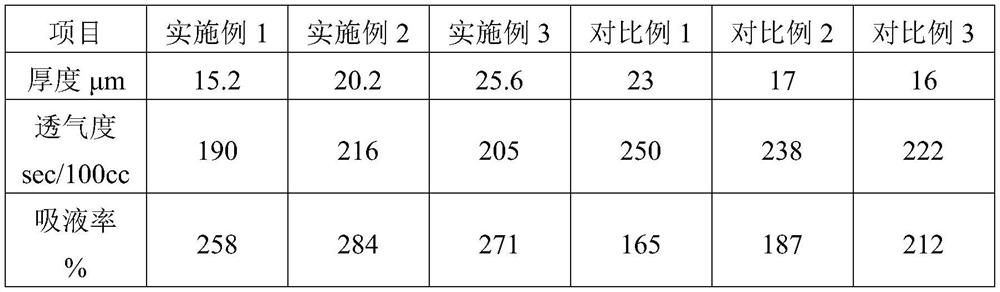

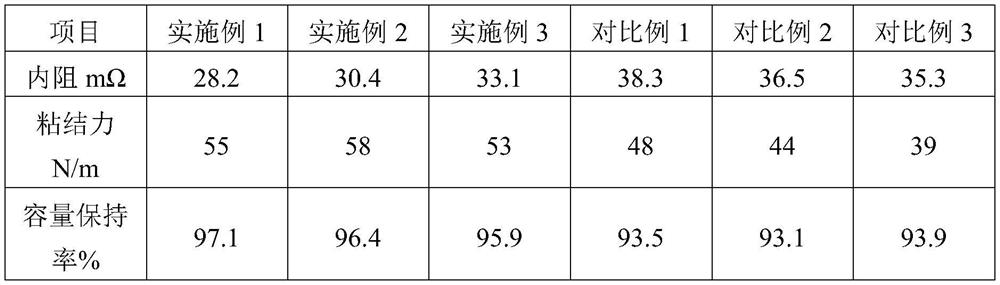

Embodiment 1

[0046] Weigh 95 parts of vinylidene fluoride-hexafluoropropylene copolymer emulsion by mass fraction, its solid content is 20%, 5 parts of polyethyl methacrylate emulsion, its solid content is 58%, mix uniformly and stir at room temperature for 10 minutes to obtain Mixed emulsion, the PVDF mixed emulsion is coated on both sides of a polyethylene-based film with a thickness of 15 μm and a porosity of 40% by gravure coating, and the coating speed is 20m / min; a three-stage oven is used for drying, each The temperature of the stage oven was 55°C, 70°C, and 60°C, respectively, and after drying, a water-based PVDF-coated lithium-ion battery separator was prepared. The thickness of the composite separator was 15.2 μm, and the thickness of each side coating was 0.1 μm.

Embodiment 2

[0048] Weigh 90 parts of polyvinylidene fluoride emulsion according to mass fraction, its solid content is 30%, 10 parts of polymethyl acrylate emulsion, its solid content is 40%, mix uniformly and stir at room temperature for 15 minutes to obtain mixed emulsion, adopt narrow slit type Coating method The PVDF mixed emulsion is coated on one side of a polyethylene-based film with a thickness of 20 μm and a porosity of 38%. °C, 60 °C, 55 °C, after drying, a water-based PVDF-coated lithium-ion battery separator was prepared, the thickness of the composite diaphragm was 20.2 μm, and the thickness of the coating was 0.2 μm.

Embodiment 3

[0050] Weigh 92 parts of vinylidene fluoride-hexafluoropropylene copolymer emulsion by mass fraction, its solid content is 35%, 8 parts of polybutyl methacrylate emulsion, its solid content is 48%, mix uniformly and stir at room temperature for 8 minutes to obtain Mixed emulsion, the PVDF mixed emulsion is coated on both sides of a polyethylene-based film with a thickness of 25 μm and a porosity of 45% by dip coating, and the coating speed is 30m / min; a three-stage oven is used for drying. The oven temperatures at all levels were 60°C, 80°C, and 70°C, and after drying, a water-based PVDF-coated lithium-ion battery separator was prepared. The thickness of the composite separator was 25.6 μm, and the thickness of each side coating was 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com