Fluorocarbon coating liquid and solar backboard

A technology of solar back sheet and coating liquid, applied in the field of solar back sheet, can solve the problem of low reflectivity, achieve the effects of anti-aging packaging strength, satisfying packaging strength and good reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

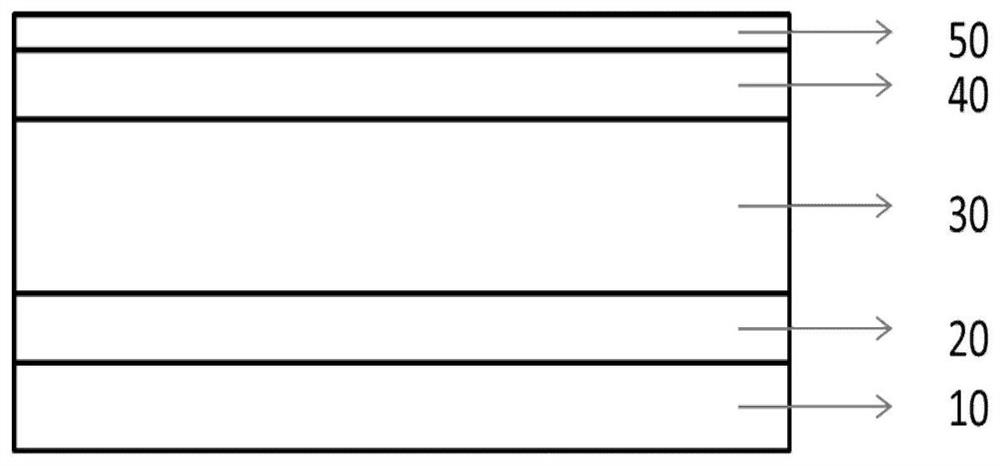

[0064] The preparation method of the solar backplane film provided by the invention comprises the following steps:

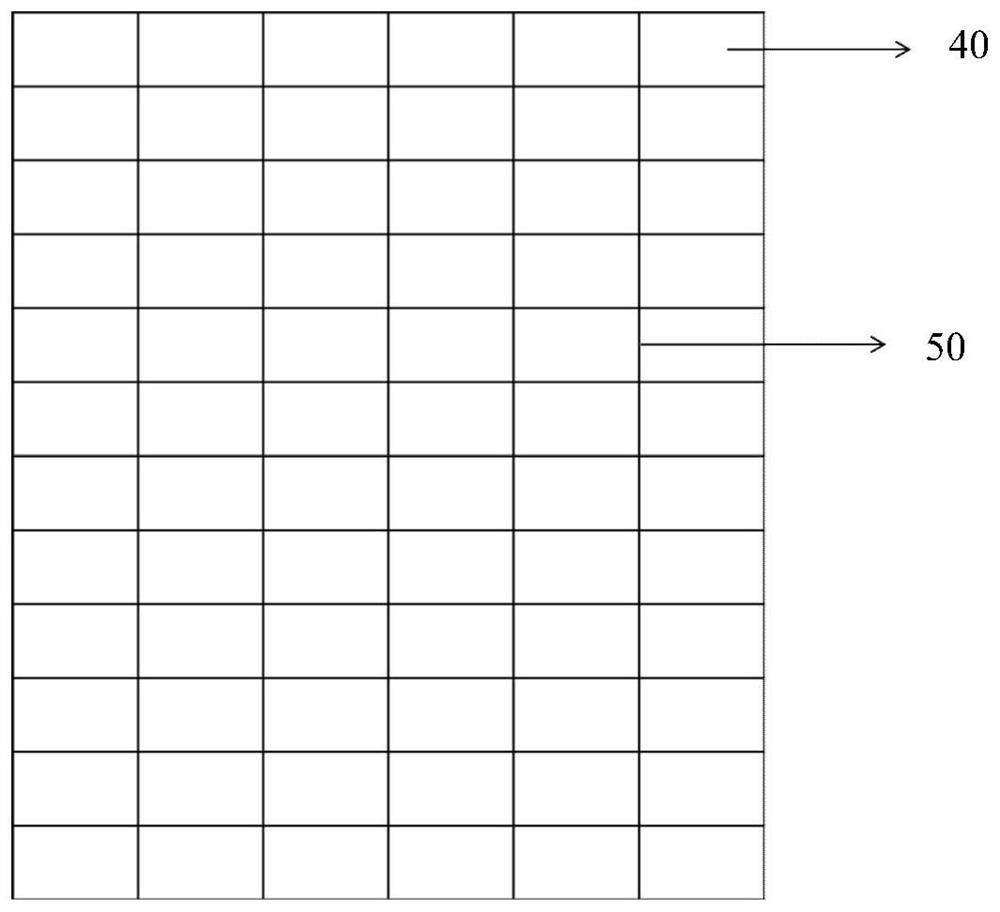

[0065] (1) Coat the white coating solution on the surface of the substrate, and place it in a circulation oven for curing to form a white fluorocarbon coating; (2) Use grid printing to print black grid fluorine on the white fluorocarbon layer The carbon layer is placed in a circulation oven for heat curing to form a black grid-like fluorocarbon coating; (3) Coat the other side of the semi-finished substrate coated with a black grid fluorocarbon layer with an adhesive to form an adhesive layer and place it on the Circulating oven drying treatment, and then composite fluorine film layer; (4) curing the finished solar backsheet; (5) laminating the fluorocarbon layer and EVA of the solar backsheet to prepare a simulated component to test the packaging strength.

[0066] Further, (1) in the process, the drying temperature of the circulating oven for the treatment of ...

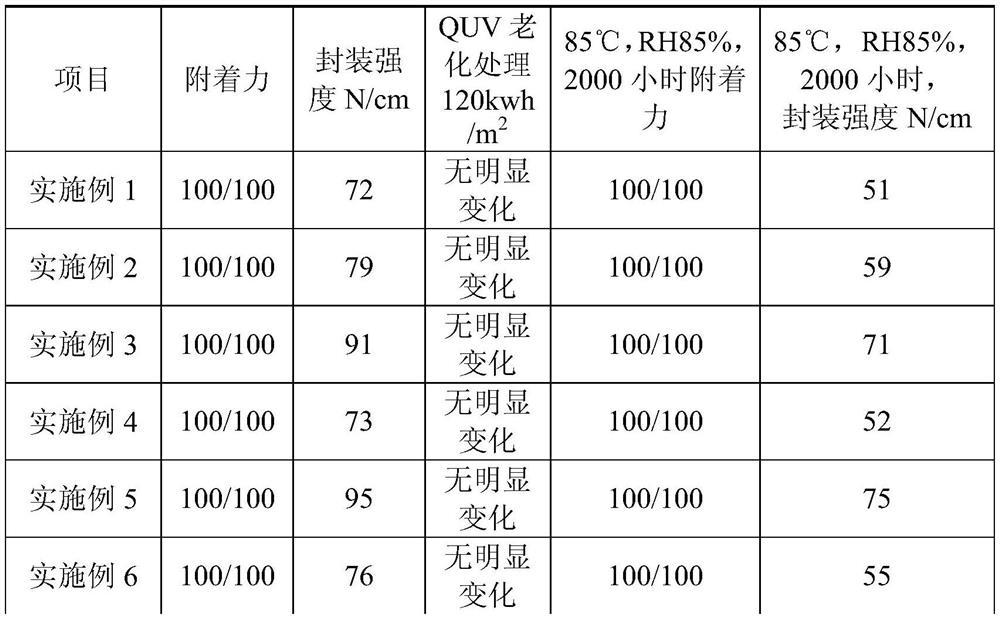

Embodiment 1

[0083] This embodiment provides a kind of fluorocarbon coating liquid, the preparation method of this fluorocarbon coating liquid comprises:

[0084] 61% polytetrafluoroethylene type fluorocarbon resin, 3.1% high-pigment carbon black, particle size 5-15nm, 30% thermoplastic polyurethane, 2% matting silica particles, 0.3% polyacrylate, 3.6% isocyanate. The aforementioned raw materials were dispersed in an organic solvent to form a fluorocarbon coating solution with a solid content of 53%. Among them, polytetrafluoroethylene type fluorocarbon resin is provided by Daikin Fluorochemical Co., Ltd., carbon black is provided by Mitsubishi Corporation of Japan, thermoplastic polyurethane is provided by Croda Chemicals, matting agent is provided by Grace Co., Ltd., polyacrylate is provided by BYK Chemicals Provided, the isocyanate is provided by Bayer, and the organic solvent is butyl acetate.

[0085] Apply the fluorocarbon coating solution on the white fluorocarbon coating and cure...

Embodiment 2

[0090] This embodiment provides a kind of fluorocarbon coating liquid, the preparation method of this fluorocarbon coating liquid comprises:

[0091] 80% polytetrafluoroethylene type fluorocarbon resin, 3% high-pigment carbon black, particle size 5-15nm, 11% thermoplastic polyurethane, 2.5% matting silica particles, 0.3% polyacrylate, 3.2 % isocyanate. The aforementioned raw materials are dispersed in an organic solvent to form a fluorocarbon coating solution with a solid content of 65%. Among them, polytetrafluoroethylene type fluorocarbon resin is provided by Daikin Fluorochemical Co., Ltd., carbon black is provided by Mitsubishi Corporation, thermoplastic polyurethane is provided by Croda Chemicals, matting agent is provided by Grace Co., Ltd., and polyacrylate is provided by BYK Chemicals , the isocyanate is provided by Bayer, and the organic solvent is butyl acetate.

[0092] Apply the fluorocarbon coating solution on the white coating of the preform, and form a black g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com